Welcome to this expert deconstruction of the FAW J6P Crankshaft, the “spine” of the engine for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

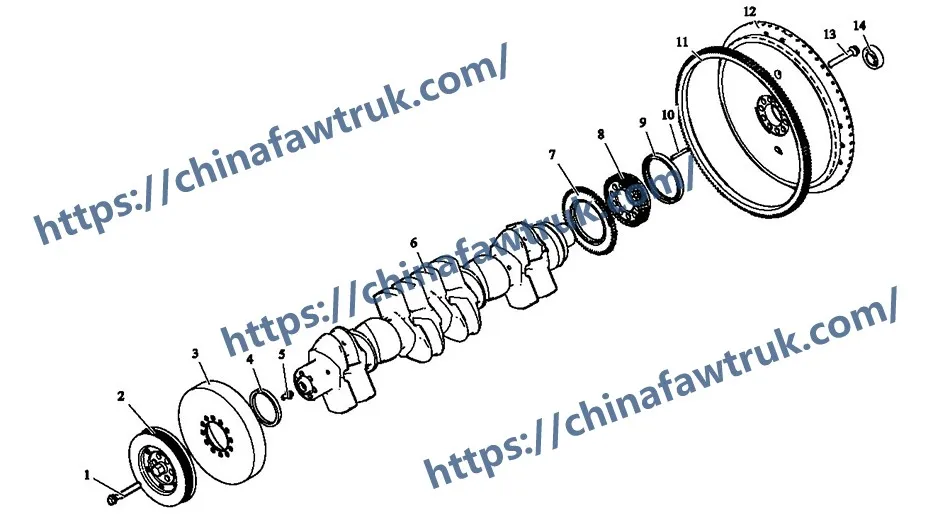

This is not a single part but a complete “Logic Assembly” of 14 components, all engineered to perform one task: to convert the violent, linear force of six pistons into the smooth, continuous rotational power that moves the truck.

The “logic” of the FAW J6P Crankshaft (P/N 1005014-36D) is all about force-transfer and balance, making it the most critical component for engine reliability.

The “Metallurgy Logic” of the FAW J6P Crankshaft is its most important feature. This is not a cast-iron component; it is drop-forged from a single billet of high-tensile steel. This “forged logic” is essential to withstand the two opposing forces that try to destroy it: the “compression” (the downward push of the combustion stroke) and the “tension” (the high-RPM “stretch” as it pulls the piston back up). The entire assembly, from the ‘Silicone oil damper’ at the front to the ‘Flywheel’ at the back, is a precisely balanced system designed to run for millions of cycles without failure.

This technical guide is an essential resource for engine rebuilders, machine shop technicians, and fleet parts managers. We will deconstruct the entire 14-component group into its four primary “logic” systems: the “Structural Core Logic” (the crankshaft itself), the “Front-End NVH & Drive Logic” (the damper and pulley assembly), the “Rear-End Power Transfer Logic” (the flywheel assembly), and the critical “Internal Sealing & Gearing Logic.” This is the complete guide to the FAW J6P Crankshaft.

This component is the literal and functional “spine” of the entire rotating assembly.

1. Component: ‘Crankshaft’ (1005014-36D / 1005014-36DB)

This (Comp 6) is the main FAW J6P Crankshaft. Its “Forged Logic” means it is forged from a single, high-tensile steel billet to handle the “compression” and “tension” forces. Its “Balancing Logic” is in the massive, integrated “counterweights.” These are precisely weighted to cancel out the massive, oscillating forces of the six pistons, providing a smooth rotation and preventing the engine from shaking itself apart. Its “Fluid Logic” is a network of internal oil galleries, drilled through the shaft. Oil is fed *in* via the main bearings and flows *out* through the “rod journals” to lubricate the connecting rod bearings. This internal lubrication is the lifeblood of the FAW J6P Crankshaft.

This group of components bolts to the “nose” or front of the FAW J6P Crankshaft. Its logic is to dampen vibration and drive the engine’s accessories.

1. The “NVH Damping” Logic: ‘Silicone oil damper’ (1005190-36D) & ‘Damper bolt’ (1005048K29D)

This is the “harmonic damper” (Comp 3). Its “logic” is critical: every combustion stroke *twists* the FAW J6P Crankshaft slightly. This is “torsional vibration.” This damper, which is a heavy steel ring floating in a layer of silicone oil, is “tuned” to that exact frequency. It oscillates *out of phase* with the crank, absorbing the twisting energy and turning it into heat. This “damping logic” prevents the FAW J6P Crankshaft from finding its resonant frequency and shattering. It is held on by six (6) ‘Damper bolts’ (Comp 1).

2. The “Accessory & Timing” Logic: (Comp 2, 4, 8)

The ‘Multi-groove belt pulley’ (Comp 2) bolts to the damper. Its “logic” is to transfer the crank’s rotation to the serpentine belt, which drives the alternator, water pump, and A/C compressor. The ‘Crankshaft timing gear’ (Comp 8) is a toothed gear that drives the engine’s camshaft and/or injection pump, ensuring the valves and fuel are “timed” perfectly. The ‘Front oil seal’ (Comp 4) is the “dynamic seal logic,” a high-temperature rubber lip seal that rides on the front of the crank, keeping the oil inside the crankcase.

This group bolts to the rear flange of the FAW J6P Crankshaft. Its logic is to store rotational energy and provide the mounting surface for the clutch and transmission.

1. Component: ‘Flywheel’ (1005121-630-0000)

This (Comp 12) is the “Rotational Battery.” Its “Inertia Logic” is its massive weight. Each combustion stroke is a single “punch.” The flywheel’s mass “stores” this energy, smoothing out the pulses into the continuous, usable rotation needed to move the truck. Its “Clutch Logic” is its large, perfectly flat, machined “friction surface.” The clutch disc presses against this surface, which is how 100% of the engine’s power is transferred to the transmission. The ‘Thrust ring’ (Comp 11) is likely part of this flywheel interface.

2. The “Fastener & Alignment” Logic: (Comp 10, 13)

The ‘Positioning key’ (Comp 10) is a small steel key. Its “logic” is to ensure the flywheel can only be installed onto the FAW J6P Crankshaft in *one* exact position. This is critical for timing and balance. The ‘Flywheel bolts’ (Comp 13) are the “Critical Fastener Logic.” The list calls for 10 high-tensile bolts. These are almost always “Torque-to-Yield” (TTY) bolts that are *single-use* and must be replaced to prevent the flywheel from detaching under load.

This final group consists of the serviceable components that are either pressed onto or housed within the FAW J6P Crankshaft.

1. Component: ‘Oil pump drive gear – crankshaft’ (1005039-36D)

This (Comp 7) is the “Lifeblood Logic.” This gear is pressed onto the FAW J6P Crankshaft, usually near the front. Its sole purpose is to drive the engine’s oil pump. If this gear fails, the oil pump stops, and the entire engine (including the FAW J6P Crankshaft itself) will be destroyed from oil starvation in minutes.

2. Component: ‘Rear oil seal’ (1005060-29D)

This (Comp 9) is the “Main Seal Logic.” It is a large-diameter, high-temperature rubber seal that is pressed into the engine block or a seal housing. Its “dynamic sealing” logic allows the FAW J6P Crankshaft to spin freely while preventing oil from leaking out of the “rear main” of the engine. A failure here results in a large, hard-to-fix oil leak between the engine and transmission.

3. Component: ‘Ball bearing 60305-2RS’ (GB/T 276-1994)

This (Comp 14) is the “Pilot Bearing Logic.” This small, sealed bearing is pressed into a recess in the *very end* of the FAW J6P Crankshaft. Its “logic” is to support the “nose” of the transmission’s input shaft. This ensures the transmission shaft stays perfectly centered with the crankshaft. A failed pilot bearing will cause a grinding noise when the clutch is pressed and make shifting gears very difficult.

The following table provides the complete, detailed breakdown of all 14 component types identified in this FAW J6P Crankshaft assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1005048K29D | Damper bolt | 6 |

| 2 | 1005046-36D | Multi-groove belt pulley – crankshaft | 1 |

| 3 | 1005190-36D | Silicone oil damper | 1 |

| 4 | 1005050-29D | Front oil seal | 1 |

| 5 | Q1841020 | Hexagon flange bolt | 12 |

| 6 | 1005014-36D (1005014-36DB) | Crankshaft (Fully interchangeable) | 1 |

| 7 | 1005039-36D | Oil pump drive gear – crankshaft | 1 |

| 8 | 1005037-29D | Crankshaft timing gear | 1 |

| 9 | 1005060-29D | Rear oil seal | 1 |

| 10 | 1005031-29D | Positioning key – main drive gear & flywheel | 1 |

| 11 | 1005122-29D | Thrust ring | 1 |

| 12 | 1005121-630-0000 | Flywheel | 1 |

| 13 | 1005071K29D | Flywheel bolt | 10 |

| 14 | GB/T 276-1994 60305-2RS | Ball bearing 60305-2RS | 1 |

The specifications for the FAW J6P Crankshaft Assembly are defined by its function as the central rotating mass of the engine.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Crankshaft, Pulley & Flywheel Assembly |

| Main Crankshaft P/N | 1005014-36D / 1005014-36DB |

| Material Logic | Drop-Forged High-Tensile Steel Billet |

| Primary Logic | Convert Linear Force to Rotational Torque, Internal Lubrication |

| Front-End NVH Logic | ‘Silicone oil damper’ (1005190-36D) |

| Front-End Drive Logic | ‘Multi-groove belt pulley’ (1005046-36D) |

| Rear-End Inertia Logic | ‘Flywheel’ (1005121-630-0000) |

| Rear-End Fastener Logic | ‘Flywheel bolt’ (1005071K29D) – Qty 10 (TTY, Single-Use) |

| Internal Gearing | ‘Crankshaft timing gear’ (1005037-29D), ‘Oil pump drive gear’ (1005039-36D) |

| Sealing System | ‘Front oil seal’ (1005050-29D) & ‘Rear oil seal’ (1005060-29D) |

| Transmission Interface | ‘Ball bearing 60305-2RS’ (Pilot Bearing) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.