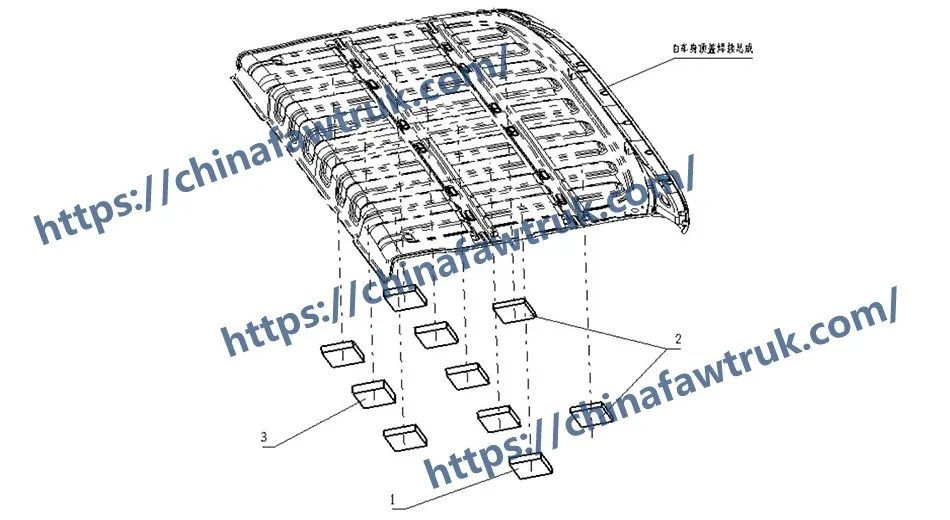

Bienvenido a esta guía esencial para el Conjunto de panel de cubierta de techo, un sistema clave para el FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado. Esta deconstrucción se centra en la 3 Tipos críticos de bloques espaciadores que constituyen este conjunto.. Estas no son partes simples; Están diseñados para sellar y amortiguar vibraciones..

El Conjunto de panel de cubierta de techo (Sistema 140) se refiere al conjunto de componentes que soportan y sellan el panel principal del techo de la cabina J6P. En un camión volquete pesado, el techo está sujeto a intensas vibraciones, torsión-giro del chasis, y exposición ambiental constante. Esta guía analizará los tres bloques espaciadores distintos. (A, B, y C) que son fundamentales para la integridad estructural del techo y su capacidad para sellar.

Este componente representa el principal, bloque espaciador más numeroso utilizado en el Conjunto de panel de cubierta de techo. Su elevada cantidad indica su papel como principal elemento portante y amortiguador..

1. Componente: «Bloque distanciador para panel de cubierta de tejado A’ (5702061-B35) – Cantidad 7

Este (compensación 1) es el “A” bloque espaciador. Con una cantidad de siete, estos son los caballos de batalla del Conjunto de panel de cubierta de techo. Están distribuidos estratégicamente en toda la estructura del techo para brindar un soporte uniforme y consistente al panel principal..

La lógica de amortiguación es su función principal.. El panel del techo de la cabina de un camión es un gran, pieza plana de metal, lo que lo hace altamente susceptible a los tambores y las vibraciones., como un gran altavoz. El motor diésel del CA3250P66K2L1T1E y el terreno accidentado en el que opera transmiten constante, vibraciones de baja frecuencia.

Estos siete bloques (compensación 1) están hechos de una alta densidad, elastómero que absorbe vibraciones, como caucho EPDM. Su propósito es “flotar” el panel del techo, aislándolo de la subestructura metálica de la cabina. Actúan como pequeños amortiguadores en cada uno de los siete puntos., Interrumpiendo el camino de la vibración..

Esto evita que el techo resuene., lo que reduce drásticamente el nivel de ruido (Nvh, o ruido, Vibración, y dureza) dentro de la cabina. Una 'A faltante o endurecida’ El bloqueo es una causa común de un persistente, Ruido de zumbido o traqueteo difícil de encontrar.

La lógica del espaciado también es fundamental.. Estos bloques crean un preciso, espacio de aire diseñado entre el panel exterior del techo y la estructura interior de la cabina. Este hueco es vital para el aislamiento térmico., ayudando a mantener la cabina más fresca bajo el sol. También asegura que el panel del techo mantenga su contorno aerodinámico correcto..

Este componente es el segundo tipo de bloque en el Conjunto de panel de cubierta de techo. Su cantidad de dos sugiere un específico, aplicación simétrica, probablemente diferente de la 'A’ bloques.

1. Componente: «Bloque espaciador para panel de cubierta de techo B’ (5702071-B35) – Cantidad 2

Este (compensación 2) es el “B” bloquear. La cantidad de dos implica fuertemente un espejo, aplicación izquierda/derecha. Es probable que se encuentren en los pilares C de la cabina o a lo largo del borde trasero del techo., uno a cada lado.

La lógica de localización puede ser su propósito.. Mientras que la 'A’ Los bloques proporcionan soporte general., estos dos 'B’ Los bloques pueden tener una forma o densidad diferente.. Podrían diseñarse para soportar una carga diferente o para ubicar con precisión el panel del techo durante el montaje..

Por ejemplo, Estos bloques pueden colocarse en puntos estructurales clave donde el panel del techo experimenta más “atroz” o fuerza de torsión cuando el chasis del camión se flexiona. Colocando dos bloques especializados en estos puntos., Los ingenieros de FAW pueden agregar rigidez y soporte adicionales donde más se necesita.

La lógica del sellado de agua también es una gran posibilidad.. Estos bloques, como parte de la mayor Conjunto de panel de cubierta de techo, son fundamentales para el sello ambiental de la cabina. El “B” Los bloques pueden estar ubicados cerca de una costura o un canal de agua. (riel de goteo).

Su diseño único podría consistir no solo en soportar el panel sino también en crear un sello de alta compresión que evite que el agua se filtre debajo del panel del techo y dentro de la cabina.. Un fallo de uno de estos 'B’ Los bloques podrían ser la causa directa de una fuga de agua..

Este último componente del Conjunto de panel de cubierta de techo es un solo, bloque único, apuntando a una aplicación altamente específica y crítica.

1. Componente: «Bloque distanciador para panel de cubierta de tejado C’ (5702081-B35) – Cantidad 1

Este (compensación 3) es el “C” bloquear. Con una cantidad de solo uno., no es una pieza de uso general. Este es un localizador especializado, probablemente con una forma única, densidad, o propiedad material, diseñado para un solo, punto específico en el techo.

La 'llave’ o 'Índice’ La lógica es su función más probable.. Este único bloque podría ser el “maestro” localizador para toda Conjunto de panel de cubierta de techo. Durante la instalación en la línea de montaje., esta 'C’ El bloque puede encajar en una ranura u orificio correspondiente en la estructura de la cabina..

esto seria “llave” el panel del techo, asegurándose de que esté perfectamente alineado (adelante/atrás y de lado a lado) *antes* de cualquiera de los otros sujetadores para el 'A’ y 'B’ los bloques están asegurados. Esto evita la desalineación, garantiza espacios de panel consistentes, y es crucial para el correcto funcionamiento de los demás sellos..

Alternativamente, este único bloque podría ubicarse debajo de un punto de alta tensión, como la base de montaje para una antena, una bocina de aire, o una luz marcadora. En este caso, la 'C’ bloque sería un reforzado, Disco de alta densidad diseñado para absorber las vibraciones y cargas específicas de ese componente auxiliar..

La lógica del modo de falla para todo este Conjunto de panel de cubierta de techo es consistente. Durante muchos años, los tres tipos de bloques (A, B, y C) Se endurecerá por la exposición a los rayos UV y al calor.. Se comprimirán y perderán su elasticidad..

cuando esto sucede, el panel del techo se aflojará. El síntoma principal será un ruido fuerte o “enlatado de aceite” sonido desde el techo. Un síntoma secundario serán las fugas de agua.. La lógica del servicio es clara: Estos bloques son un conjunto completo.. Si se retira el panel del techo para realizar el mantenimiento, es obligatorio reemplazar todos 10 bloques (7 A, 2 B, 1 C) para restaurar la amortiguación y el sellado de fábrica.

La siguiente tabla proporciona la información completa, desglose detallado de todos 3 tipos de componentes en el Conjunto de panel de cubierta de techo (Sistema 140) Para FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 5702061-B35 | Bloque distanciador para panel de cubierta de tejado A | 7 |

| 2 | 5702071-B35 | Bloque espaciador para panel de cubierta de techo B | 2 |

| 3 | 5702081-B35 | Bloque distanciador para panel de cubierta de tejado C | 1 |

Las especificaciones para el Conjunto de panel de cubierta de techo se definen por su función como sistema de sellado y amortiguación de vibraciones multipunto para la cabina J6P.

| Solicitud de vehículo | FAW Jiefang CA3250P66K2L1T1E 6×4 Camión de la basura |

| Grupo de sistema | Conjunto de panel de cubierta de techo |

| Referencia de ensamblaje | 140 |

| Lógica primaria | Amortiguación NVH, Espaciado estructural, & Sellado ambiental |

| Material componente | Elastómero de alta densidad (P.EJ., Caucho EPDM) |

| Componentes totales en el conjunto | 10 (Bloques espaciadores totales) |

| Componente tipo A | 'Espaciador… A’ (5702061-B35) – Cantidad 7 (Soporte distribuido) |

| Componente tipo B | 'Espaciador… B’ (5702071-B35) – Cantidad 2 (Simétrico/Localización) |

| Componente tipo C | 'Espaciador… C’ (5702081-B35) – Cantidad 1 (Especializado/Clave) |

| Utilidad | Recomendado para reemplazar como un juego completo de 10 piezas. |

| Sistema asociado | Estructura de la cabina & Panel de techo |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.