FAW Russian Front Axle Sensor Logic: Synchronizing 4 Precision Units for Absolute Steering Stability

The FAW Russian Front Axle Sensor logic assembly is the primary data acquisition point for the Anti-Lock Braking System (ABS) on the steering axle of the CA3250P66K24L1TE5Z dump truck. In the treacherous driving conditions of the Russian Arctic, where steering control is often compromised by black ice, the FAW Russian Front Axle Sensor provides the millisecond-accurate wheel speed data necessary to prevent lockups. This guide details the specialized bracketry, sensor technology, and wiring protection that make up the FAW Russian Front Axle Sensor assembly, ensuring directional authority is maintained even during panic stops at -50°C.

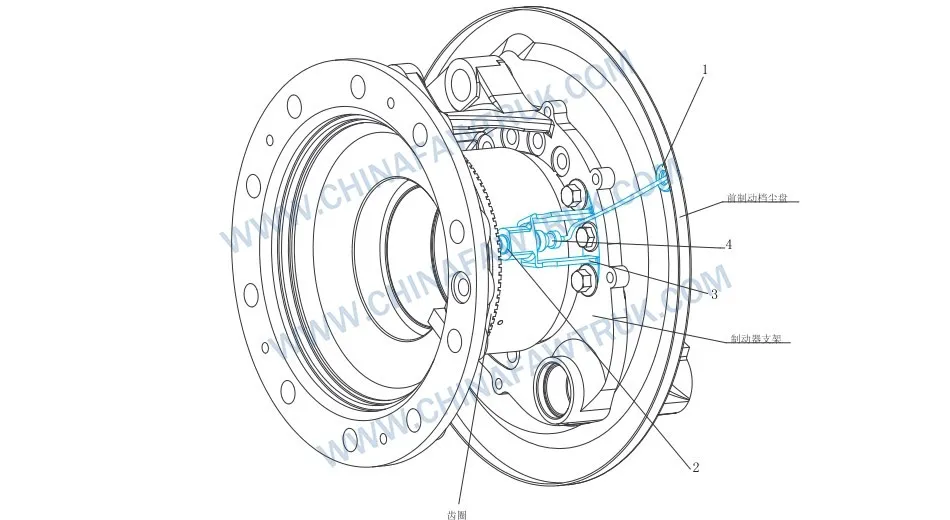

FAW Russian Front Axle Sensor

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3550221-6S | Wheel Speed Sensor Wire Bushing | 1 |

| 2 | 3550361-6S | Sensor Sleeve | 1 |

| 3 | 3605215-820 | Wheel Speed Sensor Bracket Assembly | 1 |

| 4 | 3605360-820 | Wheel Speed Sensor Assembly | 1 |

Sensor Technology: The Eye of the ABS

The cornerstone of the FAW Russian Front Axle Sensor logic is the Wheel Speed Sensor Assembly (Part No. 3605360-820). This inductive sensor is tasked with monitoring the rotation of the front wheels, which are the most critical for directional stability. Unlike rear sensors that simply manage traction, the FAW Russian Front Axle Sensor must provide data that allows the ECU to differentiate between a skid and a steering input. The sensor head contains a coil wound around a permanent magnet, encased in a stainless steel shell to resist the impact of gravel flung by the tires.

The voltage signal generated by the FAW Russian Front Axle Sensor is an analog sine wave created by the passing teeth of the pole wheel (tone ring). In the specific context of the Russian market, the sensor’s internal circuitry is reinforced to handle “cold soak” conditions. Standard sensors can suffer from internal open circuits when the potting compound contracts at -45°C, severing the fine copper wires. The Wheel Speed Sensor Assembly used in the FAW Russian Front Axle Sensor kit utilizes a low-expansion epoxy and flexible internal leads to ensure continuity is maintained regardless of the ambient temperature.

Signal clarity is another priority for the FAW Russian Front Axle Sensor. The front axle is located near the alternator and high-current starter cables, sources of significant electromagnetic interference (EMI). The sensor cable features a braided shield and twisted-pair wiring to reject this noise. If the FAW Russian Front Axle Sensor signal were corrupted by EMI, the ABS might trigger falsely during normal braking, extending stopping distances rather than shortening them. This high-fidelity signal ensures that the truck stops safely and predictably on the variable surfaces of a mining haul road.

Mounting Architecture: The Bracket Assembly

The physical stability of the FAW Russian Front Axle Sensor is secured by the Wheel Speed Sensor Bracket Assembly (Part No. 3605215-820). This is not a simple stamped part; it is a precision-machined component designed to align the sensor tip perfectly with the tone ring inside the wheel hub. The front axle experiences significant shock loads as the truck hits potholes and ruts. The bracket must be rigid enough to prevent the FAW Russian Front Axle Sensor from vibrating, which would modulate the air gap and create a “phantom” speed signal.

The mounting location of the Wheel Speed Sensor Bracket Assembly on the steering knuckle presents a unique challenge: the cable must accommodate the steering angle. As the wheel turns from lock to lock, the distance between the sensor and the chassis harness changes. The bracket design includes specific routing guides to ensure the cable loops correctly without snagging on the brake chamber or suspension arms. This dynamic cable management is a key feature of the FAW Russian Front Axle Sensor logic, protecting the wiring from fatigue failure.

Corrosion resistance is also built into the Wheel Speed Sensor Bracket Assembly. Exposed to the spray of de-icing chemicals, a standard steel bracket would rust and swell, potentially crushing the sensor body. The FAW Russian Front Axle Sensor bracket is treated with a heavy-duty zinc-flake coating or galvanization. This ensures that the sensor can be removed for service years down the line. A seized sensor often results in the destruction of the bracket during removal, so this corrosion protection directly lowers the long-term maintenance costs of the FAW Russian Front Axle Sensor system.

The Interface: Sleeve and Bushing Logic

The interface between the static bracket and the adjustable sensor is managed by the Sensor Sleeve (Part No. 3550361-6S). This component is the unsung hero of the FAW Russian Front Axle Sensor assembly. It creates a friction fit that holds the sensor in place against the vibration of the road but allows it to be pushed back if the wheel bearing runout causes the tone ring to strike the sensor tip. This “push-back” capability is a critical self-preservation mechanism for the FAW Russian Front Axle Sensor, preventing the sensor head from being sheared off during extreme suspension articulation events.

The material of the Sensor Sleeve is a high-memory spring copper or stainless steel alloy. In the FAW Russian Front Axle Sensor specification, this material must retain its elasticity at sub-zero temperatures. If the sleeve loses its grip in the cold, the sensor will back out of the bore, increasing the air gap. An excessive air gap weakens the voltage signal, causing the ABS light to illuminate and disabling the safety system. Therefore, the clamping force of the Sensor Sleeve is a vital parameter for the reliability of the FAW Russian Front Axle Sensor.

Cable protection is further enhanced by the Wheel Speed Sensor Wire Bushing (Part No. 3550221-6S). This rubber grommet secures the cable as it exits the harsh environment of the wheel end and enters the protected chassis rail. In the FAW Russian Front Axle Sensor design, this bushing prevents the cable insulation from chafing against the sharp edges of the metal bracketry. Made from EPDM rubber, it remains flexible in the Russian winter, ensuring a watertight seal around the cable and preventing moisture from wicking into the harness.

Diagnostics and Replacement Best Practices

Diagnosing issues with the FAW Russian Front Axle Sensor usually involves a multimeter and an oscilloscope. The resistance across the sensor pins should typically fall between 1100 and 1800 ohms. However, an insulation resistance test is equally important for the FAW Russian Front Axle Sensor; checking for shorts to ground can reveal if the internal windings have touched the housing due to thermal expansion damage. When spinning the wheel by hand, the sensor should generate at least 0.2V AC; if it doesn’t, the air gap managed by the Sensor Sleeve is likely too large.

When replacing the Wheel Speed Sensor Assembly, it is mandatory to replace the Sensor Sleeve (Part No. 3550361-6S) simultaneously. Reusing an old sleeve in the FAW Russian Front Axle Sensor setup invites failure, as the metal memory is fatigued and will not hold the new sensor securely. The bore in the Wheel Speed Sensor Bracket Assembly must be cleaned of all rust and old grease using a wire brush. Applying a specialized dielectric grease to the sensor body can help prevent future seizure, but standard anti-seize should be avoided if it contains conductive metallic particles that could interfere with the magnetic flux.

Finally, the routing of the cable through the Wheel Speed Sensor Wire Bushing must be checked for proper slack. The steering should be turned fully left and right to ensure the cable is not pulled tight. The FAW Russian Front Axle Sensor is only as reliable as its connection to the truck. By ensuring the cable is stress-free and the sensor is securely seated in a new sleeve, maintenance teams can guarantee the active safety of the vehicle in the most challenging driving conditions.

Conclusion: Steering with Confidence

The FAW Russian Front Axle Sensor logic assembly is a compact system with an outsized impact on vehicle safety. By converting wheel rotation into digital data, it allows the truck to maintain steering control during emergency braking on ice. The 4 components—the sensor, bracket, sleeve, and bushing—form a cohesive unit designed to survive the rigors of the Russian environment.

For fleet operators, the FAW Russian Front Axle Sensor is a non-negotiable safety item. Using genuine parts ensures that the signal characteristics match the ECU’s expectations, preventing false ABS activation. By maintaining these sensors and their mounting hardware, fleets ensure that their drivers have the technology they need to navigate safely, protecting both the personnel and the valuable machinery in their charge.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.