FAW Russian Atmospheric Temperature Sensor Logic: Orchestrating 4 Precision Elements for Optimized Arctic Combustion

The FAW Russian Atmospheric Temperature Sensor logic assembly is the environmental awareness unit for the CA3250P66K24L1TE5Z dump truck. In the extreme climate of the Russian Federation, where ambient temperatures can swing from -50°C to +30°C, the engine management system relies entirely on the FAW Russian Atmospheric Temperature Sensor to calculate air density and determine the precise fuel injection mass. This guide analyzes the sensor unit, its specialized mounting architecture, and the critical fasteners that ensure this sensitive instrument survives the vibration and corrosion of the mining sector.

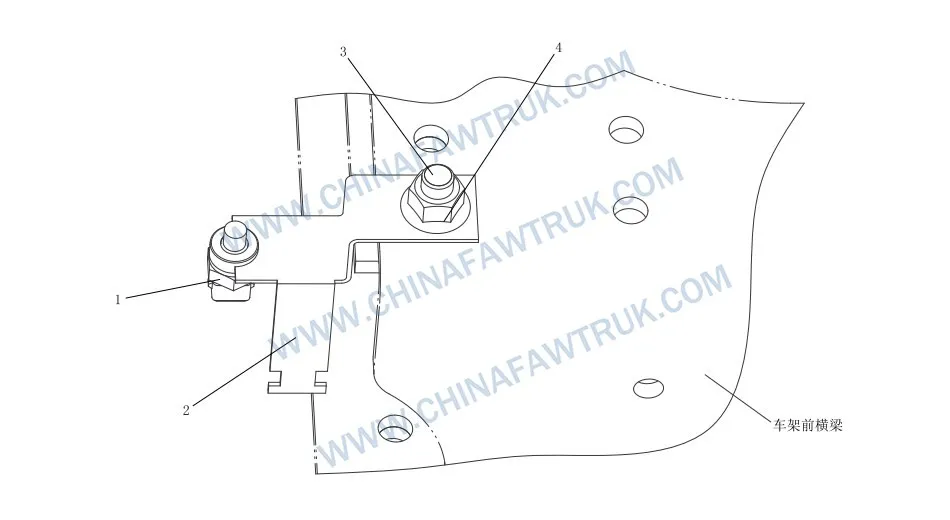

FAW Russian Atmospheric Temperature Sensor

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3602155-60D-C00 | Temperature Sensor Assembly | 1 |

| 2 | 3602520-64R | Atmospheric Temperature Sensor Bracket Assembly | 1 |

| 3 | Q1841440 | Hexagon Flange Bolt (Coarse Shank/Standard) | 1 |

| 4 | CQ39614 | Hexagon Flange Nut | 1 |

Precision Sensing in Cryogenic Conditions

The primary functional unit of the FAW Russian Atmospheric Temperature Sensor assembly is the Temperature Sensor Assembly (Part No. 3602155-60D-C00). This is not a generic thermistor; it is a specialized automotive-grade sensor designed with a Negative Temperature Coefficient (NTC) element encased in a thermal-conductive polymer shell. In the context of the FAW Russian Atmospheric Temperature Sensor, this component serves as the reference point for the entire engine control strategy. The “60D-C00” designation indicates a specific calibration curve optimized for the CA3250P66K24L1TE5Z engine, providing enhanced resolution at the lower end of the temperature spectrum, specifically between -40°C and 0°C.

In the Russian Arctic, air density varies significantly compared to temperate zones. Cold air is denser, containing more oxygen per cubic meter. Without accurate data from the FAW Russian Atmospheric Temperature Sensor, the ECU might underestimate the air mass entering the cylinders, leading to a lean fuel mixture. A lean mixture in a high-compression diesel engine in winter can cause hard starting, rough idling, and in severe cases, failure to generate sufficient combustion heat to warm the block. The Temperature Sensor Assembly ensures that the fuel injection timing and duration are perfectly matched to the density of the intake air, facilitating immediate cold starts and smooth power delivery.

The construction of the Temperature Sensor Assembly also addresses the issue of thermal lag. The sensing tip is exposed to the airflow but protected by a cage structure to prevent damage from road debris or ice impact. This design allows the FAW Russian Atmospheric Temperature Sensor to react almost instantaneously to changes in ambient conditions—for example, when the truck moves from a heated workshop into a blizzard. This rapid response prevents the engine from running “rich” or “lean” during the critical transition period, optimizing fuel economy and reducing raw hydrocarbon emissions during the warm-up phase.

Structural Integrity: The Bracket Assembly

Mounting a precision instrument on a heavy-duty dump truck requires a robust interface, provided here by the Atmospheric Temperature Sensor Bracket Assembly (Part No. 3602520-64R). This bracket is more than a simple piece of metal; it is an engineered isolation unit. The location of the FAW Russian Atmospheric Temperature Sensor is critical—it must be in a stream of fresh air, away from engine heat soak, yet protected from direct wheel spray. The Atmospheric Temperature Sensor Bracket Assembly positions the sensor precisely to meet these conflicting requirements, often near the intake snorkel or behind the front grille, shielded from the radiator’s thermal plume.

The material choice for the Atmospheric Temperature Sensor Bracket Assembly reflects the corrosive reality of Russian roads, which are heavily treated with chloride-based de-icing salts. FAW utilizes a heavy-gauge steel for this bracket, treated with a multi-stage zinc-nickel coating or e-coating process. This ensures that the bracket does not rust and fail, which would leave the FAW Russian Atmospheric Temperature Sensor dangling by its wiring harness—a scenario that inevitably leads to wire fatigue, signal shorting, and a “Check Engine” light that grounds the vehicle.

Furthermore, the rigidity of the Atmospheric Temperature Sensor Bracket Assembly prevents harmonic vibration. Diesel engines generate significant low-frequency vibration that can shatter delicate electronic solder joints. The bracket is designed with stiffening ribs to raise its natural frequency above the engine’s idle vibration range. By stabilizing the Temperature Sensor Assembly, the bracket ensures that the data stream remains clean and uninterrupted, proving that mechanical engineering is just as vital to the FAW Russian Atmospheric Temperature Sensor system as electronic design.

Fastener Logic: Securement in High Vibration

The security of the entire logic assembly depends on the Hexagon Flange Bolt (Coarse Shank/Standard) (Part No. Q1841440) and the Hexagon Flange Nut (Part No. CQ39614). While these may appear to be standard hardware, their specification is integral to the FAW Russian Atmospheric Temperature Sensor reliability. The “Coarse Shank” designation of the bolt indicates a design optimized for shear strength. In the high-vibration environment of a dump truck chassis, fine-thread bolts can sometimes loosen or strip more easily if the bracket shifts. The coarse thread profile provides a deeper engagement, resisting the micro-movements that lead to fastener back-off.

The Hexagon Flange Nut (Part No. CQ39614) complements the bolt by distributing the clamping load over a wider surface area of the bracket. This integrated flange eliminates the need for a separate washer, reducing the part count and potential points of failure during field service. The face of the flange is often serrated, biting into the Atmospheric Temperature Sensor Bracket Assembly to create a mechanical lock. For the FAW Russian Atmospheric Temperature Sensor, this locking action is the primary defense against the constant shaking induced by driving on corrugated haul roads or frozen earth.

Additionally, the metallurgy of these fasteners is selected to minimize galvanic corrosion. The Atmospheric Temperature Sensor Bracket Assembly and the chassis rail may be of different steel grades. The Hexagon Flange Bolt acts as the bridge between them. Using a bolt with the correct sacrificial coating ensures that the fastener does not seize in place, allowing for easy removal if the sensor needs to be relocated or the bracket replaced. Maintenance of the FAW Russian Atmospheric Temperature Sensor requires checking the torque on these fasteners to ensure the system remains physically secure.

System Integration and Maintenance

The FAW Russian Atmospheric Temperature Sensor is not an isolated component; it is a node in the vehicle’s Controller Area Network (CAN). The Temperature Sensor Assembly connects to the main chassis harness via a weather-sealed connector. While the connector itself is part of the sensor pigtail, its security is managed by the bracketry. Proper routing ensures that water does not wick down the wires into the sensor body. Any compromise in the wiring insulation near the Atmospheric Temperature Sensor Bracket Assembly can lead to signal corruption, causing the ECU to default to a “safe mode” value (usually -40°C or +20°C), which can severely hamper engine performance.

Diagnostics for the FAW Russian Atmospheric Temperature Sensor involve checking the resistance across the sensor terminals against a temperature chart. Technicians should also inspect the Hexagon Flange Bolt and Hexagon Flange Nut for tightness and corrosion. A loose bracket can cause the sensor to rattle against the chassis, physically damaging the plastic housing or the internal element. In the dusty environment of a mine, the sensor tip can also become coated with mud or grime, insulating it from the ambient air. Cleaning the Temperature Sensor Assembly is a simple but vital maintenance task to ensure accurate readings.

Ultimately, the FAW Russian Atmospheric Temperature Sensor dictates how the engine breathes. By ensuring the air-fuel ratio is correct for the specific density of the air, it protects the engine from running too hot (lean) or washing the cylinders with excess fuel (rich). Fleet operators must recognize that this small assembly, held on by a single Hexagon Flange Bolt, is the keystone of fuel efficiency. Replacing a faulty Temperature Sensor Assembly with a genuine FAW part restores the engine’s ability to adapt to the harsh Russian environment, ensuring longevity and power.

Conclusion: Small Part, Massive Impact

The FAW Russian Atmospheric Temperature Sensor logic assembly proves that size does not equate to importance in modern automotive engineering. These 4 components—the sensor, bracket, bolt, and nut—form a vital link between the environment and the engine’s computer brain. The precision of the Temperature Sensor Assembly enables the CA3250P66K24L1TE5Z to operate efficiently in one of the world’s most hostile climates.

For maintenance professionals, the simplicity of the FAW Russian Atmospheric Temperature Sensor assembly should not lead to complacency. Ensuring the Atmospheric Temperature Sensor Bracket Assembly is secure and the sensor is clean is essential for optimal vehicle performance. By adhering to the breakdown provided and using only genuine fasteners like the Hexagon Flange Bolt, operators ensure that their fleet remains responsive, efficient, and ready for the cold.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.