FAW Russian Front-Axle Reduction Gearbox: Engineering 39 Strategic Components for Ultimate 6×6 Traction

The FAW Russian Front-Axle Reduction Gearbox assembly represents the spearhead of the CA3250P66K24L1TE5Z dump truck’s all-wheel-drive capability. Situated within the front axle housing, this intricate logic assembly manages the primary gear reduction and the critical inter-wheel differential locking mechanism. In the unforgiving frozen tundra of the Russian Federation, where traction determines survival, this gearbox must convert high-speed driveshaft rotation into massive, ground-churning torque. This comprehensive guide deconstructs the 39 essential components, from the precision-machined drive bevel gear to the pneumatic differential lock actuators, ensuring that the FAW Russian Front-Axle Reduction Gearbox delivers unyielding performance in temperatures as low as -40°C.

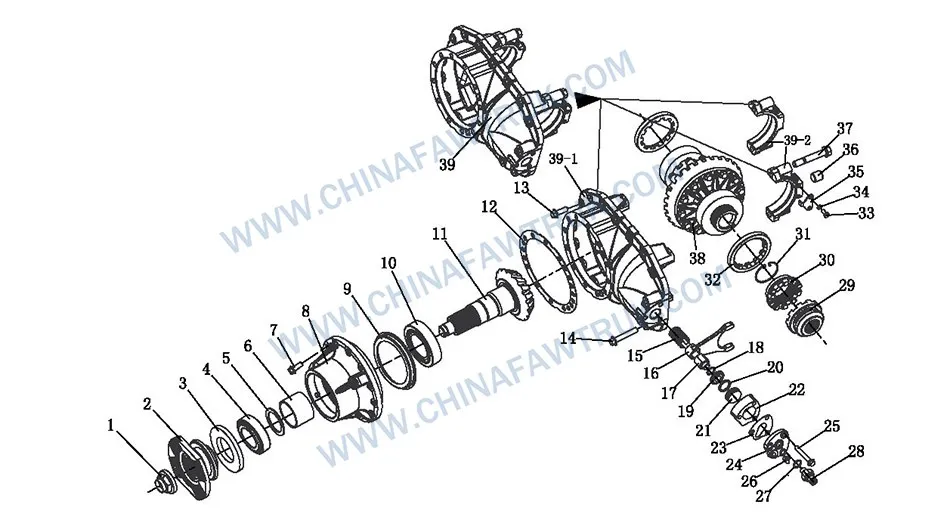

FAW Russian Front-Axle Reduction Gearbox

Input Precision: Flanges and Oil Seals

The entry point for power into the FAW Russian Front-Axle Reduction Gearbox is the Flange Assembly (Part No. 2502065-557). This heavy-duty forged component connects the front driveshaft to the input pinion. It is secured by the high-torque Lock Nut – 2nd Shaft Flange (Part No. 1701471-11), which applies the necessary preload to the bearing stack. In the FAW Russian Front-Axle Reduction Gearbox, the rigidity of this connection is paramount. Any looseness at the flange translates to backlash in the gears, which can shatter the teeth under the shock loads of off-road driving.

Sealing this rotating interface against the harsh Russian elements is the job of the Drive Bevel Gear Oil Seal Assembly (Part No. 2302055-820-C00). This is not a standard seal; it is a multi-lip, cassette-style seal designed to operate in an environment of abrasive mud, ice, and chemical road salts. The material composition of the seal is critical for the FAW Russian Front-Axle Reduction Gearbox. It utilizes advanced fluoroelastomers that retain flexibility at -40°C, ensuring that the gear oil remains inside the housing and contaminants remain out.

Furthermore, the Bearing Seat – 1st Front Axle Drive Bevel Gear (Part No. 2302049-820) provides the structural housing for the input assembly. This casting is precision-machined to hold the outer races of the tapered roller bearings. It features an integrated Oil Shield – Drive Bevel Gear Bearing Seat (Part No. 2402048-A0E) to manage oil flow. This shield prevents oil churned by the ring gear from flooding the front bearing, ensuring that the FAW Russian Front-Axle Reduction Gearbox maintains optimal lubrication levels without aeration or overheating.

Reduction Logic: Bevel Gears and Tapered Rollers

The heart of the FAW Russian Front-Axle Reduction Gearbox is the Drive Bevel Gear – 1st Front Axle (Part No. 2302036A820). This pinion gear features a hypoid tooth profile, which allows for a larger contact patch and smoother operation compared to spiral bevel gears. The metallurgy of this gear is specifically formulated for the high-torque, low-speed crawling typical of dump truck operations. It must resist pitting and fatigue fracture under extreme loads.

Supporting the immense axial and radial loads generated by the hypoid gear mesh are the Tapered Roller Bearing units (Part Nos. 30312 and 30314). The FAW Russian Front-Axle Reduction Gearbox utilizes a “stiff” bearing arrangement to maintain precise gear alignment. If the pinion gear deflects under load, the tooth contact pattern shifts, leading to noise and rapid failure. These bearings are preloaded using the Adjusting Shim – Drive Bevel Gear Bearing (Part No. 2402081-557) and separated by the Spacer – Drive Bevel Gear Bearing (Part No. 2402088-557).

The precise adjustment of this bearing stack is the most critical aspect of assembling the FAW Russian Front-Axle Reduction Gearbox. The shim thickness determines the pinion depth and bearing preload. In the Russian Arctic, thermal contraction of the housing can increase bearing preload. Therefore, the setup specifications for the FAW Russian Front-Axle Reduction Gearbox are calibrated to account for a wide operating temperature range, ensuring the bearings do not seize during a cold start or become loose during heavy hauling.

Traction Control: The Inter-Wheel Lock

A defining feature of the FAW Russian Front-Axle Reduction Gearbox is its integrated inter-wheel differential lock. This system is crucial for maintaining mobility on ice. The mechanism is pneumatically actuated via the Cylinder – Inter-wheel Diff Lock (Part No. 2406011-A0E) and Piston – Inter-wheel Diff Lock (Part No. 2406013-A0E). When the driver activates the switch, compressed air enters the cylinder through the Terminal Elbow Joint (Part No. CQ63505), forcing the piston to move.

The sealing of this pneumatic circuit relies on the O-Ring – Diff Lock Piston (Part No. 2406014-55R) and the Gasket – Cylinder Cover (Part No. 2406017-A0E). In the FAW Russian Front-Axle Reduction Gearbox, these rubber components are made from low-temperature compounds. Standard O-rings would freeze and shrink at -40°C, causing air leaks and preventing the lock from engaging. The reliability of these seals ensures that the driver has instant access to 6×6 traction when needed.

The piston movement is transmitted to the Shift Fork – Inter-wheel Diff Lock (Part No. 2306024-820) via the Shift Fork Shaft – Inter-wheel Diff (Part No. 2306026-820). This fork pushes the Sliding Gear Sleeve – Inter-wheel Diff (Part No. 2306032-820) to lock the axle shafts together via the Fixed Gear Sleeve – Inter-wheel Diff Lock (Part No. 2306033-820). The FAW Russian Front-Axle Reduction Gearbox design ensures that this mechanism is robust enough to handle engagement under load without bending or jamming.

Housing Logic: Structural Containment

Containing the massive forces of the reduction gear is the Reducer Housing – 1st Front Axle (Part No. 2302018-820). This casting is designed with extreme rigidity to prevent gear deflection. Along with the Cap – Diff Bearing (Part No. 2402019-557), it forms the rigid cradle for the Differential Assembly – 1st Front Axle (Part No. 2303010A820). The FAW Russian Front-Axle Reduction Gearbox housing is manufactured from nodular iron to resist shock fracturing in cold climates.

The differential carrier is secured by Support Pin – Reducer & Axle Housing (Part No. 2402021-A0E) and Bolt – Diff Bearing Cap (Part No. 2402087-A6D). These fasteners are critical for maintaining the position of the differential ring gear relative to the pinion. The Adjusting Ring – Differential Bearing (Part No. 2403071-A8R) allows for the precise setting of backlash and carrier bearing preload, a setting that is locked in place by the Locking Plate – Adjusting Ring (Part No. 2303072-820).

Structural integrity is maintained by a multitude of high-tensile Lock Bolts (Part Nos. 2402043-557, 2402016-557, 2302016-820). These bolts secure the bearing housing and the differential carrier. The FAW Russian Front-Axle Reduction Gearbox utilizes pre-applied thread lockers or mechanical locking features to prevent these bolts from backing out under the severe vibration of off-road use. The sheer number of bolts reflects the immense internal forces trying to separate the gear housing.

Component Breakdown: 129. Front Axle Reducer Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | 1701471-11 | Lock Nut – 2nd Shaft Flange | 1 |

| 2 | 2502065-557 | Flange Assembly | 1 |

| 3 | 2302055-820-C00 | Drive Bevel Gear Oil Seal Assembly | 1 |

| 4 | 30312 | Tapered Roller Bearing | 1 |

| 5 | 2402081-557 | Adjusting Shim – Drive Bevel Gear Bearing | 1 |

| 6 | 2402088-557 | Spacer – Drive Bevel Gear Bearing | 1 |

| 8 | 2302049-820 | Bearing Seat – 1st Front Axle Drive Bevel Gear | 1 |

| 9 | 2402048-A0E | Oil Shield – Drive Bevel Gear Bearing Seat | 1 |

| 10 | 30314 | Tapered Roller Bearing | 1 |

| 11 | 2302036A820 | Drive Bevel Gear – 1st Front Axle | 1 |

| 15 | 2306028-820 | Return Spring – Inter-wheel Diff Lock | 1 |

| 16 | 2306024-820 | Shift Fork – Inter-wheel Diff Lock | 1 |

| 20 | 2406014-55R | O-Ring – Diff Lock Piston | 1 |

| 21 | 2406013-A0E | Piston – Inter-wheel Diff Lock | 1 |

| 22 | 2406011-A0E | Cylinder – Inter-wheel Diff Lock | 1 |

| 28 | 3774010-55A | Neutral Switch Assembly | 1 |

| 29 | 2306032-820 | Sliding Gear Sleeve – Inter-wheel Diff | 1 |

| 30 | 2306033-820 | Fixed Gear Sleeve – Inter-wheel Diff Lock | 1 |

| 31 | 2306034-820 | Wire Snap Ring – Diff Lock Fixed Gear Sleeve | 1 |

| 32 | 2403071-A8R | Adjusting Ring – Differential Bearing | 2 |

| 35 | 2303072-820 | Locking Plate – Adjusting Ring | 2 |

| 38 | 2303010A820 | Differential Assembly – 1st Front Axle | 1 |

| 39 | 2302015-820 | Reducer Housing & Diff Bearing Cap Assembly | 1 |

Conclusion: The Pinnacle of Traction Engineering

The FAW Russian Front-Axle Reduction Gearbox is more than just a mechanism; it is the ultimate enabler of all-terrain mobility. By combining high-precision hypoid gears with a robust, pneumatically actuated differential lock, FAW has created a front drive unit that offers both highway efficiency and unstoppable off-road traction. The careful selection of cold-resistant materials for seals and gaskets ensures that this performance is maintained even in the harshest Siberian winters.

For fleet operators, the complexity of this assembly underscores the need for genuine parts. Substituting a generic seal or an incorrect shim pack can lead to rapid failure of the bevel gears or the differential lock. By adhering to the specifications of the FAW Russian Front-Axle Reduction Gearbox and using only authentic components, maintenance teams can guarantee the long-term reliability and safety of their heavy-duty fleet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.