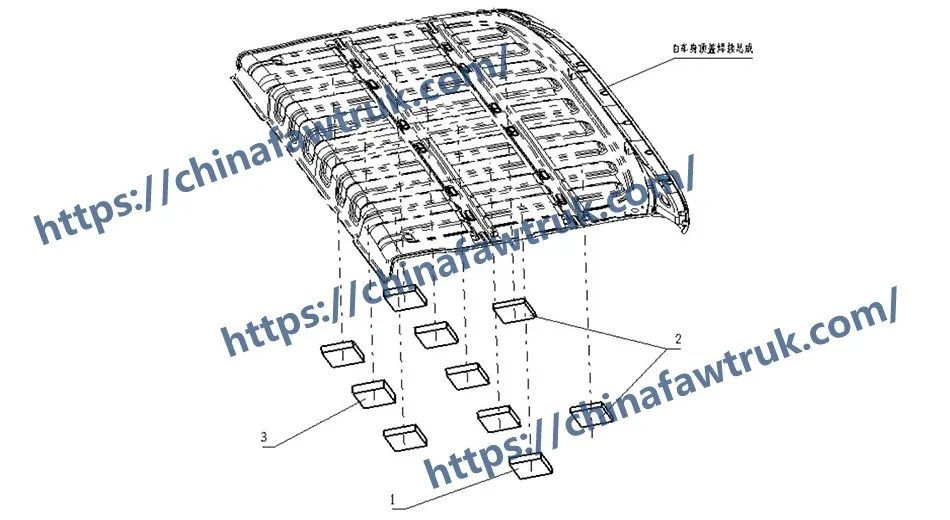

Welcome to this essential guide to the Roof Cover Panel Assembly, a key system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction focuses on the 3 critical types of spacer blocks that constitute this assembly. These are not simple parts; they are engineered for sealing and vibration damping.

The Roof Cover Panel Assembly (System 140) refers to the set of components that support and seal the main roof panel of the J6P cab. On a heavy-duty dump truck, the roof is subjected to intense vibration, torque-twist from the chassis, and constant environmental exposure. This guide will analyze the three distinct spacer blocks (A, B, and C) that are critical to the roof’s structural integrity and its ability to seal.

This component represents the primary, most numerous spacer block used in the Roof Cover Panel Assembly. Its high quantity points to its role as the main load-bearing and damping element.

1. Component: ‘Spacer block for roof cover panel A’ (5702061-B35) – Qty 7

This (Comp 1) is the “A” spacer block. With a quantity of seven, these are the workhorses of the Roof Cover Panel Assembly. They are strategically distributed across the roof structure to provide even and consistent support for the main panel.

The Damping Logic is their primary function. The roof panel of a truck cab is a large, flat piece of metal, which makes it highly susceptible to drumming and vibration, like a large speaker. The CA3250P66K2L1T1E’s diesel engine and the rough terrain it operates on transmit constant, low-frequency vibrations.

These seven blocks (Comp 1) are made from a high-density, vibration-absorbing elastomer, like EPDM rubber. Their purpose is to “float” the roof panel, isolating it from the cab’s metal sub-structure. They act as small shock absorbers at each of the seven points, interrupting the path of vibration.

This prevents the roof from resonating, which dramatically reduces the noise level (NVH, or Noise, Vibration, and Harshness) inside the cab. A missing or hardened ‘A’ block is a common cause of a persistent, hard-to-find rattle or humming noise.

The Spacing Logic is also critical. These blocks create a precise, engineered air gap between the outer roof panel and the inner cab structure. This gap is vital for thermal insulation, helping to keep the cab cooler in the sun. It also ensures that the roof panel maintains its correct aerodynamic contour.

This component is the second type of block in the Roof Cover Panel Assembly. Its quantity of two suggests a specific, symmetrical application, likely different from the ‘A’ blocks.

1. Component: ‘Spacer block for roof cover panel B’ (5702071-B35) – Qty 2

This (Comp 2) is the “B” block. The quantity of two strongly implies a mirrored, left/right-hand application. These are likely found on the cab’s C-pillars or along the rear edge of the roof, one on each side.

The Locating Logic may be their purpose. While the ‘A’ blocks provide general support, these two ‘B’ blocks may have a different shape or density. They could be designed to handle a different load or to precisely locate the roof panel during assembly.

For example, these blocks might be positioned at key structural points where the roof panel experiences the most “racking” or twisting force as the truck’s chassis flexes. By placing two specialized blocks at these points, FAW engineers can add extra stiffness and support where it is needed most.

The Water Sealing Logic is also a strong possibility. These blocks, as part of the greater Roof Cover Panel Assembly, are critical to the cab’s environmental seal. The “B” blocks may be located near a seam or a water channel (drip rail).

Their unique design might be to not only support the panel but also to create a high-compression seal that prevents water from wicking under the roof panel and into the cab. A failure of one of these ‘B’ blocks could be the direct cause of a water leak.

This final component of the Roof Cover Panel Assembly is a single, unique block, pointing to a highly specific and critical application.

1. Component: ‘Spacer block for roof cover panel C’ (5702081-B35) – Qty 1

This (Comp 3) is the “C” block. With a quantity of only one, it is not a general-purpose part. This is a specialized locator, likely with a unique shape, density, or material property, designed for a single, specific point on the roof.

The ‘Key’ or ‘Index’ Logic is its most probable function. This single block could be the “master” locator for the entire Roof Cover Panel Assembly. During installation on the assembly line, this ‘C’ block might fit into a corresponding slot or hole in the cab structure.

This would “key” the roof panel, ensuring it is perfectly aligned (fore/aft and side-to-side) *before* any of the other fasteners for the ‘A’ and ‘B’ blocks are secured. This prevents misalignment, guarantees consistent panel gaps, and is crucial for the proper function of the other seals.

Alternatively, this single block could be located under a high-stress point, such as the mounting base for an antenna, an air horn, or a marker light. In this case, the ‘C’ block would be a reinforced, high-density puck designed to absorb the specific vibrations and loads of that auxiliary component.

The Failure Mode Logic for this entire Roof Cover Panel Assembly is consistent. Over many years, all three types of blocks (A, B, and C) will harden from UV and heat exposure. They will compress and lose their elasticity.

When this happens, the roof panel will loosen. The primary symptom will be a loud rattle or “oil-canning” sound from the roof. A secondary symptom will be water leaks. The Service Logic is clear: these blocks are a complete set. If the roof panel is removed for service, it is mandatory to replace all 10 blocks (7 A, 2 B, 1 C) to restore the factory-spec damping and sealing.

The following table provides the complete, detailed breakdown of all 3 component types in the Roof Cover Panel Assembly (System 140) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5702061-B35 | Spacer block for roof cover panel A | 7 |

| 2 | 5702071-B35 | Spacer block for roof cover panel B | 2 |

| 3 | 5702081-B35 | Spacer block for roof cover panel C | 1 |

The specifications for the Roof Cover Panel Assembly are defined by its function as a multi-point vibration damping and sealing system for the J6P cab.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Roof Cover Panel Assembly |

| Assembly Reference | 140 |

| Primary Logic | NVH Damping, Structural Spacing, & Environmental Sealing |

| Component Material | High-Density Elastomer (e.g., EPDM Rubber) |

| Total Components in Set | 10 (Total Spacer Blocks) |

| Component Type A | ‘Spacer… A’ (5702061-B35) – Qty 7 (Distributed Support) |

| Component Type B | ‘Spacer… B’ (5702071-B35) – Qty 2 (Symmetrical/Locating) |

| Component Type C | ‘Spacer… C’ (5702081-B35) – Qty 1 (Specialized/Key) |

| Serviceability | Recommended to replace as a complete 10-piece set |

| Associated System | Cab Structure & Roof Panel |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.