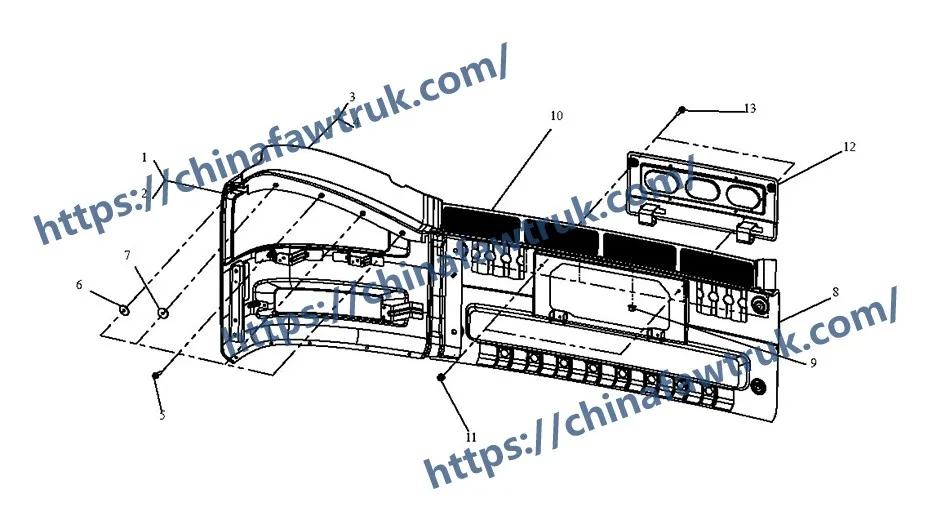

This is a technical deconstruction of the FAW J6P Front Bumper, designed for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide breaks down the 13 serviceable component types, including the main sections, integrated steps, and hardware, providing a complete guide for repair and replacement.

The FAW J6P Front Bumper is a multi-piece, modular assembly engineered for durability and serviceability. As the first line of defense for the chassis in harsh, off-road conditions, its design is critical. It is not a single piece, but a three-part system (left, right, and center) allowing for a damaged section to be replaced without replacing the entire unit. This deconstruction will analyze the main structural components, the integrated access steps, and the specific high-strength hardware used to mount the FAW J6P Front Bumper to the truck’s frame. A fully intact FAW J6P Front Bumper is essential for both vehicle protection and operator safety.

This group represents the main body of the FAW J6P Front Bumper. The 3-piece design is a critical engineering choice for heavy-duty dump trucks, prioritizing serviceability and reduced repair costs.

1. Component: ‘Bumper Middle Assy’ (2803010-70U) – Qty 1

This (Comp 8) is the central, structural backbone of the FAW J6P Front Bumper. It is typically the largest and strongest section, as it protects the radiator and engine components directly behind it. It also serves as the mounting base for the license plate holder (Comp 12).

2. Component: ‘Front Bumper Left Assy’ (2803035-70U) & ‘Front Bumper Right Assy’ (2803040-70U) – Qty 1 each

These (Comp 1 & 2) are the corner sections of the FAW J6P Front Bumper. The Modular Logic is that these corners are the most frequently damaged parts in off-road or construction site incidents. By making them separate, bolt-on assemblies, a technician can replace just the damaged corner instead of the entire FAW J6P Front Bumper, saving significant time and cost.

This 3-piece design is fundamental to the FAW J6P Front Bumper‘s role on a dump truck. It ensures that impact damage can be localized and repaired efficiently, maximizing vehicle uptime. The entire FAW J6P Front Bumper assembly is designed to absorb and deflect impacts, protecting the more critical frame rails and steering components.

A key feature of the FAW J6P Front Bumper is its integration of secure, anti-slip steps. These are essential for allowing the driver to safely clean the windscreen or perform daily checks.

1. Component: ‘Left Upper Step’ (2803031B71A) & ‘Right Upper Step’ (2803032B71A) – Qty 1 each

These (Comp 3 & 4) are the primary access steps integrated into the top surface of the left and right bumper sections. They are designed with aggressive tread patterns to provide grip even when wet or muddy. These are critical safety features of the FAW J6P Front Bumper.

2. Component: ‘Upper Step – Front Bumper’ (2803096-70U) – Qty 1

This (Comp 10) is the central upper step, likely mounted on the ‘Bumper Middle Assy’ (Comp 8). This component provides a continuous, safe platform across the entire width of the FAW J6P Front Bumper, allowing the operator to move from side to side without stepping down.

The Access Logic of the FAW J6P Front Bumper demonstrates a design that considers operator workflow. These components are not just aesthetic; they are functional tools that improve maintenance efficiency and safety. A proper FAW J6P Front Bumper includes these secure stepping surfaces.

This group includes the final components and the critical hardware used to assemble the FAW J6P Front Bumper and attach it to the vehicle.

1. Component: ‘License Plate Holder Assy’ (2803080A71A) – Qty 1

This (Comp 12) is the dedicated bracket for mounting the front license plate. It is a serviceable part, designed to be bolted onto the ‘Bumper Middle Assy’ (Comp 8) using ‘Cross recessed pan head screws’ (Comp 13, Q2360516F6).

2. Component: ‘Gasket – floor heat shield’ (5109318-A01) – Qty 2

This (Comp 6) is a specialized gasket. Its presence suggests that a part of the FAW J6P Front Bumper assembly is close to a high-heat source (like the exhaust or turbo piping). This gasket is likely used to protect the bumper’s paint or composite materials from heat damage, or to protect the cab floor.

3. Component: Fastener Group (Q2360516, CQ32606, CQ34005)

This group includes ‘Cross recessed pan head screws’ (Comp 5, Qty 10), ‘Hex flange lock nuts’ (Comp 9, Qty 6), and ‘Hex nuts’ (Comp 11, Qty 2). The Fastener Logic is critical for a high-vibration component like the FAW J6P Front Bumper. The use of ‘lock nuts’ (Comp 9) is deliberate, as they provide prevailing torque to prevent the nuts from backing off, ensuring the FAW J6P Front Bumper remains secure to the chassis.

The following table provides the complete, detailed breakdown of all 13 component types in the FAW J6P Front Bumper assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing repairs on the FAW J6P Front Bumper.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2803035-70U | Front Bumper Left Assy | 1 |

| 2 | 2803040-70U | Front Bumper Right Assy | 1 |

| 3 | 2803031B71A | Left Upper Step – Front Bumper | 1 |

| 4 | 2803032B71A | Right Upper Step – Front Bumper | 1 |

| 5 | Q2360516 | Cross recessed pan head screw | 10 |

| 6 | 5109318-A01 | Gasket – floor heat shield | 2 |

| 7 | Q40206 | Large washer | 4 |

| 8 | 2803010-70U | Bumper Middle Assy | 1 |

| 9 | CQ32606 | Hex flange lock nut | 6 |

| 10 | 2803096-70U | Upper Step – Front Bumper | 1 |

| 11 | CQ34005 | Hex nut | 2 |

| 12 | 2803080A71A | License Plate Holder Assy | 1 |

| 13 | Q2360516F6 | Cross recessed pan head screw | 2 |

The specifications for the FAW J6P Front Bumper are defined by its modular, heavy-duty construction designed for the demanding environment of a 6×4 dump truck. Understanding these specifications is key to ordering the correct FAW J6P Front Bumper parts.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Front Bumper |

| Primary Logic | Modular, 3-piece assembly for protection and serviceability |

| Core Component (Left) | ‘Front Bumper Left Assy’ (2803035-70U) |

| Core Component (Middle) | ‘Bumper Middle Assy’ (2803010-70U) |

| Core Component (Right) | ‘Front Bumper Right Assy’ (2803040-70U) |

| Key Feature | Integrated anti-slip operator steps (Left, Right, Upper) |

| Ancillary Component | ‘License Plate Holder Assy’ (2803080A71A) |

| Fastener Type | High-tensile bolts and ‘Hex flange lock nuts’ (CQ32606) |

| Total Component Types | 13 |

| Associated System | Cab / Chassis Exterior. The FAW J6P Front Bumper is the primary frame protector. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.