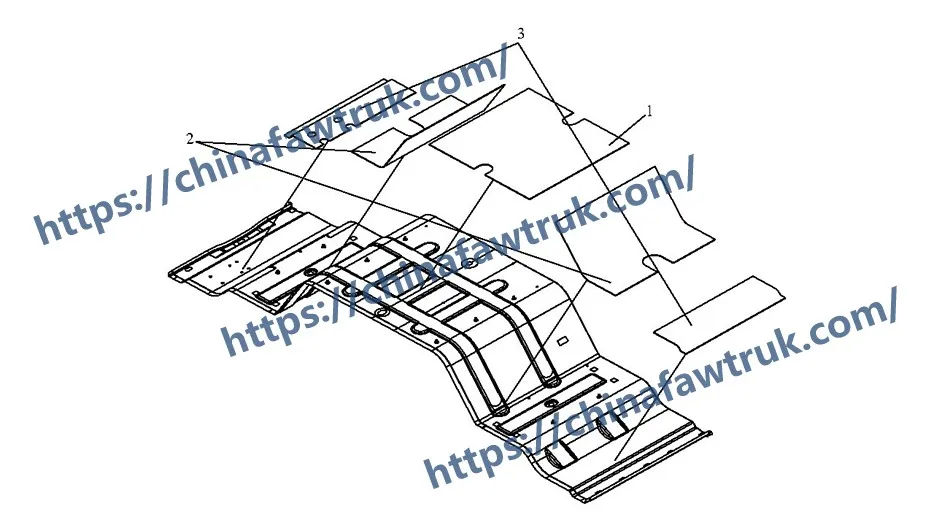

This is a comprehensive technical guide to the Soundproofing And Heat Insulation Pad system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 3 primary component types, detailing the specialized pads that form the critical acoustic and thermal barrier beneath the cab floor.

The Soundproofing And Heat Insulation Pad system is an integral part of the vehicle’s defense against operational noise and engine heat. Placed directly against the metal floor pan, this high-density material barrier is essential for maintaining driver comfort, focus, and mitigating the immense thermal energy generated by the drivetrain and exhaust system. The multi-piece design ensures full coverage across the complex floor contours.

This detailed component breakdown will delineate the unique features of the three distinct pad shapes (A, B, and C) and the material science behind their performance. A correctly fitted Soundproofing And Heat Insulation Pad is critical for cab longevity, preventing heat-related damage to in-cab components, and ensuring compliance with noise regulations. Every section of the Soundproofing And Heat Insulation Pad must be intact to maintain the full designed protection against the harsh environment of a heavy-duty truck.

The core purpose of the Soundproofing And Heat Insulation Pad is to achieve optimal acoustic isolation. This involves reducing airborne noise and structure-borne vibration, which can cause discomfort and long-term hearing issues for the driver. The pads are strategically divided to cover different zones of the cab floor, maximizing their performance.

1. Component: ‘Soundproofing/Heat Insulation Pad A’ (5109631-B35) – Qty 1

Pad A is typically the largest component, designed to cover the expansive, central flat area of the cab floor or the primary section of the transmission tunnel. Its size suggests it handles the greatest volume of noise and heat transfer. The acoustic material used in this section of the Soundproofing And Heat Insulation Pad possesses a high density, which is crucial for absorbing low-frequency rumbles inherent to a powerful diesel engine and preventing resonance within the cab structure. This singular piece provides the foundation for the entire soundproofing system.

2. Component: ‘Soundproofing/Heat Insulation Pad B’ (5109632-B35) – Qty 2

Pad B, utilized in a pair, likely addresses the footwell areas on both the driver and passenger sides. These zones are geometrically more complex, often requiring cutouts for pedals, steering column mounts, and fresh air ducts. The material integrity here must withstand frequent mechanical stress from foot traffic and operation. Since these areas are closer to the side structures, Pad B of the Soundproofing And Heat Insulation Pad is optimized for vibration damping that travels up the cab frame.

3. Component: ‘Soundproofing/Heat Insulation Pad C’ (5109633-B35) – Qty 2

Pad C, also used in a pair, may be designed for the extreme perimeter areas or the sloping toe-board near the front firewall. These areas often feature complex bends and mounting points. The material composition of this section of the Soundproofing And Heat Insulation Pad is engineered for maximum flexibility without sacrificing its sound-deadening capabilities. This ensures a seamless continuation of the acoustic barrier where the floor meets the front panel, which is vital for complete sound isolation.

The combined surface area coverage provided by Pad A, B, and C guarantees that minimal noise penetrates the protective layer. The use of multiple, interlocking sections in the Soundproofing And Heat Insulation Pad allows for easier installation and replacement compared to a single, monolithic piece, which would be cumbersome and prone to error. This design enhances both serviceability and long-term performance longevity.

Beyond sound control, the **Soundproofing And Heat Insulation Pad** serves as a robust thermal barrier. The effectiveness of the system stems from its composite material construction, which typically involves layers of dense, fibrous material and reflective surfaces.

1. Material: Reflective Foil Layer

The underside of the **Soundproofing And Heat Insulation Pad**, facing the engine compartment, is often treated or laminated with an aluminum or similar heat-reflective foil. This is the **Radiant Heat Logic** at work, reflecting the majority of infrared radiation back towards the heat source before it can conduct into the metal floor. This single feature drastically lowers the temperature increase within the cab.

2. Material: Core Insulating Layer

The core material of the **Soundproofing And Heat Insulation Pad** is typically a high-loft, closed-cell foam or heavy textile batting. This core works on the principle of **Conduction Blocking**, trapping air within its matrix to prevent heat from conducting through to the interior surface. This thickness and material choice ensure a high R-value (thermal resistance). The density of the pad is calibrated to provide both thermal and acoustic properties without creating excessive bulk that would interfere with pedal operation or seat mounting.

3. Environmental Resistance

Given the heavy-duty nature of the truck, the material used for the Soundproofing And Heat Insulation Pad must be highly resistant to common contaminants. The materials are designed not to absorb moisture, which would lead to mold, rust on the floor pan, and a drastic loss of insulating capability. They are engineered to repel oil, grease, and water, ensuring the thermal and acoustic performance of the **Soundproofing And Heat Insulation Pad** is preserved even after accidental spills or exposure to chassis washing procedures.

Proper installation of the **Soundproofing And Heat Insulation Pad** requires meticulous attention to seams and edges. Overlapping or improperly seated pads can create thermal bridges, allowing concentrated heat to pass directly through the floor and negating the system’s benefits. This attention to detail is essential for maximizing the lifespan and operational effectiveness of the Soundproofing And Heat Insulation Pad in real-world trucking environments.

Maintaining the optimal condition of the cab requires regular inspection and, when necessary, the timely replacement of the **Soundproofing And Heat Insulation Pad** components. Although designed for durability, wear and tear, especially around high-traffic areas like the driver’s footwell, is inevitable.

1. Installation Sequence

When replacing the full set, the removal of the seats, center console, and primary floor mats is mandatory to gain access to the **Soundproofing And Heat Insulation Pad**. Technicians must adhere to the factory installation sequence, usually starting with the largest central pad (Pad A, 5109631-B35) to ensure proper seating over the transmission hump, followed by the footwell pads (Pad B and C). Correct placement is not only for performance but also for proper reinstallation of the overlying floor coverings.

2. Inspection Criteria

During maintenance checks, key inspection criteria for the **Soundproofing And Heat Insulation Pad** include checking for compression set (permanent crushing due to weight or stress), tears or cuts (especially around bolt holes and pedal access points), and any evidence of water damage or microbial growth. A compromised pad in the **Soundproofing And Heat Insulation Pad** assembly must be replaced immediately to prevent further deterioration of the cab environment. Small tears can be entry points for water, accelerating corrosion of the steel floor pan beneath.

3. Component Sourcing

When sourcing replacement parts, it is crucial to use genuine FAW components. Generic insulation materials often fail to meet the specific fire-retardant, acoustic, and thermal specifications required for the Soundproofing And Heat Insulation Pad in a commercial vehicle application. Using non-specified materials can lead to regulatory non-compliance, poor driver comfort, and potential safety risks related to flammability. The specific part numbers (5109631-B35, 5109632-B35, 5109633-B35) for the Soundproofing And Heat Insulation Pad guarantee that the material composition and dimensions perfectly match the CA3250P66K2L1T1E cab chassis.

The longevity of the entire cabin structure and the continued well-being of the operator are directly linked to the performance of the Soundproofing And Heat Insulation Pad. This simple yet sophisticated system acts as the cab’s foundation for environmental protection. Its modular, three-part design facilitates target maintenance, allowing a technician to replace only the damaged section without needing to purchase the entire cab flooring system.

The following table provides the complete, detailed breakdown of all 3 component types in the Soundproofing And Heat Insulation Pad assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5109631-B35 | Soundproofing/Heat Insulation Pad A | 1 |

| 2 | 5109632-B35 | Soundproofing/Heat Insulation Pad B | 2 |

| 3 | 5109633-B35 | Soundproofing/Heat Insulation Pad C | 2 |

The specifications for the Soundproofing And Heat Insulation Pad are defined by its function as a multi-piece, high-density material barrier against cabin noise and drivetrain heat, crucial for the FAW Jiefang CA3250P66K2L1T1E dump truck.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Soundproofing And Heat Insulation Pad |

| Primary Logic | Combined acoustic damping and thermal conduction blocking |

| Pad Structure | Modular 3-piece design (Pad A, B, and C) for complete floor coverage |

| Critical Area Coverage | Engine/Transmission tunnel and front toe-board region |

| Total Component Types | 3 |

| Associated System | Cab Interior / HVAC. The Soundproofing And Heat Insulation Pad is the primary comfort barrier. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.