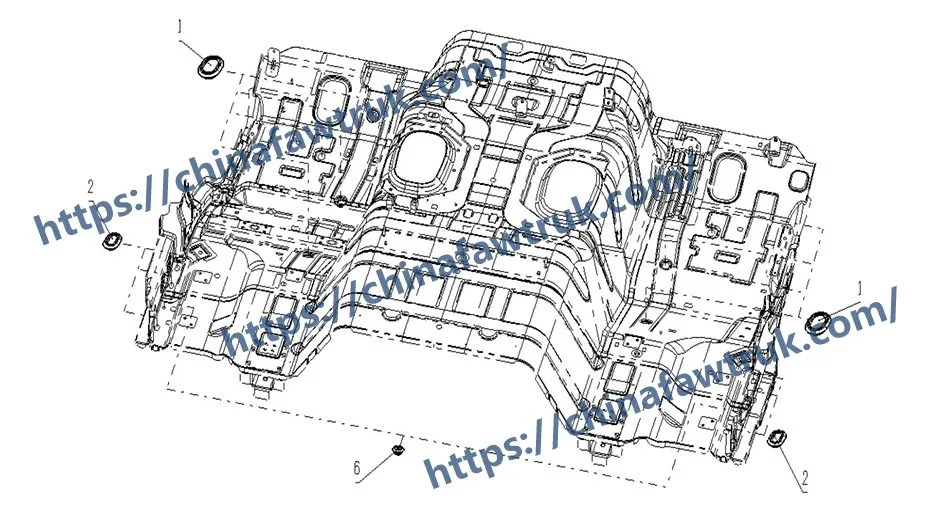

This is a comprehensive technical guide to the FAW J6P Floor Blockage assembly (Floor Plugs and Grommets) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 3 serviceable component types, detailing the specialized plugs that seal the cab floor and rear enclosure.

The FAW J6P Floor Blockage system is a vital component of the cab’s passive protection system. Its primary function is to seal the cab floor and rear enclosure against water, dust, exhaust fumes, and road noise that would otherwise enter the operator compartment. These plugs fill large, engineered holes in the metal cab structure, which are necessary for access during assembly and wiring harness installation.

The effectiveness of the **FAW J6P Floor Blockage** depends entirely on the material quality and precise fitment of each plug. A single missing or deteriorated plug in the **FAW J6P Floor Blockage** assembly can compromise the acoustic and thermal isolation of the cab, leading to significant structural corrosion over the vehicle’s lifespan. This deconstruction will analyze the types of plugs used and their specific roles in protecting the cab. The integrity of the **FAW J6P Floor Blockage** is paramount for cab longevity.

This group of components provides the main moisture barrier directly on the cab floor. These plugs seal large openings, often used for major cable routing or drainage holes during manufacturing.

1. Component: ‘Oval plug A – floor’ (5109613-A01) – Qty 8

This (Comp 1) is one type of oval-shaped plug. The Sealing Redundancy Logic is evident in the quantity; eight of these plugs are distributed across the cab floor, securing various sized holes. These are the primary defense against road spray and water pooling beneath the vehicle. The proper installation of every single plug in the FAW J6P Floor Blockage is vital.

2. Component: ‘Oval plug B – floor’ (5109612-A01) – Qty 6

This (Comp 2) is the second type of oval plug, slightly different in size or profile from Comp 1. Six of these are also installed on the cab floor. The use of different types of plugs (A and B) ensures maximum flexibility in sealing various engineered openings within the FAW J6P Floor Blockage system. Any missing component from the FAW J6P Floor Blockage allows noise and water to enter.

This component focuses on sealing the rear structure of the cab, typically the firewall or rear enclosure, which is a major source of engine noise and heat intrusion.

1. Component: ‘Plug – rear enclosure’ (5613163-A01) – Qty 2

This (Comp 3) is a specialized plug designed for the rear panel of the cab. The Acoustic Isolation Logic demands that the rear plugs be installed securely to dampen engine noise and prevent exhaust fumes from entering the cab. Two of these are used, strategically placed near the air intake or main wiring pass-throughs. The structural integrity of the FAW J6P Floor Blockage is maintained by these plugs.

2. Component: Material Integrity

All components in the FAW J6P Floor Blockage assembly are typically made from durable rubber or high-density PVC. This material choice is essential because it must remain flexible enough to install and remove but rigid enough to maintain a seal under constant vehicle vibration and extreme temperature cycling (hot engine bay below, cool cab above). This material science aspect is crucial for the FAW J6P Floor Blockage.

This group relates to the overall lifespan and service function of the FAW J6P Floor Blockage system. The plugs are designed not only to seal but also to allow technicians access.

1. Component: Service Access

The plugs (Comp 1, 2) often sit over access holes used for routing the main chassis wiring harness and brake lines up into the cab. The Maintenance Access Logic requires these plugs to be tight-fitting but removable. Their secondary role is to protect the exposed metal edges of the cab floor holes from the environment, minimizing the risk of corrosion. A rusted floor pan is a direct threat to the structural integrity of the entire cab. The FAW J6P Floor Blockage prevents this damage.

2. Component: Damage Prevention

Given the harsh conditions of a dump truck, the underside of the cab is constantly battered by road debris and high-pressure washing. The FAW J6P Floor Blockage must be resilient to these forces. Damage to a single plug allows high-pressure water to be forced into the cab, leading to rust, mold, and damage to electrical components under the seat and dashboard. This makes the simple **FAW J6P Floor Blockage** a critical component for the cab’s long-term health.

The following table provides the complete, detailed breakdown of all 3 component types in the FAW J6P Floor Blockage assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the FAW J6P Floor Blockage.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5109613-A01 | Oval plug A – floor | 8 |

| 2 | 5109612-A01 | Oval plug B – floor | 6 |

| 3 | 5613163-A01 | Plug – rear enclosure | 2 |

The specifications for the FAW J6P Floor Blockage are defined by its function as a multi-point, flexible sealing system for the cab floor and rear enclosure.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Floor Blockage (Floor Plugs/Grommets) |

| Primary Logic | Water, dust, and fume isolation for cab interior |

| Total Plugs | 16 (14 floor, 2 rear enclosure) |

| Floor Plugs P/N | 5109613-A01 (Type A) & 5109612-A01 (Type B) |

| Material | Durable rubber or high-density PVC (implied) |

| Total Component Types | 3 |

| Associated System | Cab Interior / HVAC. The FAW J6P Floor Blockage is the core barrier. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.