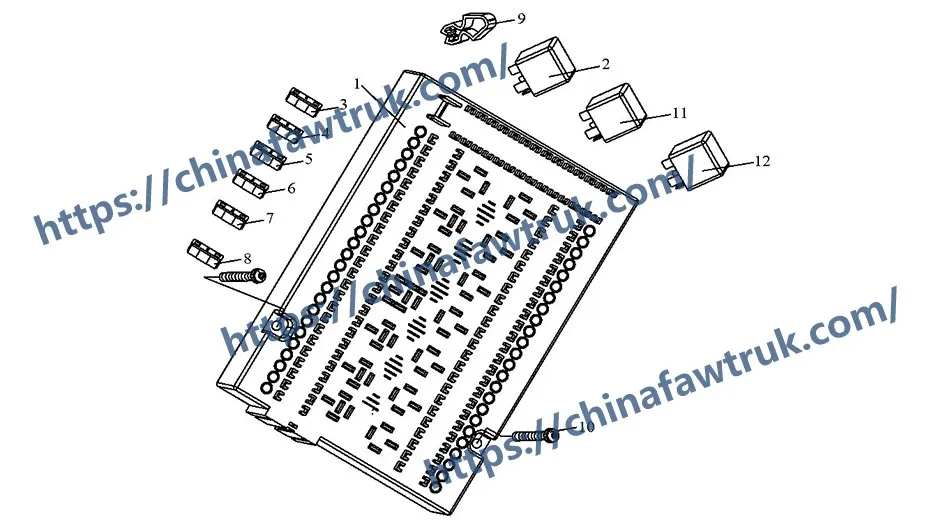

This is an in-depth technical deconstruction of the Fuse Box Assembly With Relay for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide details the 12 serviceable component types, including the main 48-circuit box, the various blade fuses, and the integrated relays that protect the cab’s electrical systems.

The Fuse Box Assembly With Relay is the central nervous system for all electrical equipment in the cab. It functions as the primary power distribution and protection hub. Located inside the cab, this module receives main power from the battery and chassis distribution box and splits it into dozens of individual, protected circuits.

Its primary role is to safeguard the vehicle’s expensive wiring harnesses and electronic modules from damage caused by over-currents and short circuits. It does this by utilizing a combination of sacrificial fuses and high-power switches (relays). This deconstruction will analyze the core components of the Fuse Box Assembly With Relay, including the main housing, the various types of relays, and the array of blade fuses. A properly functioning Fuse Box Assembly With Relay is essential for the reliability of every component, from the instrument cluster to the power windows and lights.

This component is the foundation of the entire Fuse Box Assembly With Relay. It is the physical structure that holds all the fuses and relays and contains the complex internal circuitry.

1. Component: ‘Fuse box assy (48-circuit)’ (3722010-A01) – Qty 1

This (Comp 1) is the main housing. The 48-Circuit Logic means this single box is the distribution point for 48 independent electrical circuits. Internally, it consists of a multi-layer printed circuit board (PCB) or a complex network of busbars that route power from the ‘Main relay assy’ (Comp 12) to the various fuse and relay sockets.

This design simplifies the vehicle’s wiring harness, as all circuit protection is centralized in one serviceable location. This main housing of the Fuse Box Assembly With Relay is a non-serviceable unit; if its internal busbars or PCB fails, the entire box must be replaced. Its cover (not listed) is also critical, as it protects the components from dust, moisture, and accidental shorts. The Fuse Box Assembly With Relay housing is the nerve center of the cab.

This group of components provides the “muscle” for the Fuse Box Assembly With Relay. Relays are electro-mechanical switches that use a low-current signal (from a dashboard switch) to control a high-current circuit (like headlights or a blower motor).

1. Component: ‘Main relay assy’ (3722110-417) – Qty 1

This (Comp 12) is the master switch for the entire Fuse Box Assembly With Relay. The Master Power Logic is that this large relay is typically activated by the ignition switch. When the key is turned, it sends a low-current signal to this relay, which then closes and provides high-amperage 24V power to the main busbars of the fuse box, “waking up” all the vehicle’s electrical systems.

2. Component: ‘4-pin relay assy (20A)’ (3711030-240) – Qty 9

This (Comp 2) is the most common type of relay in the Fuse Box Assembly With Relay. A 4-pin relay is a simple On/Off switch. It has two “control” pins (for the low-current signal) and two “load” pins (for the high-current circuit). These are used for functions like headlights, fog lights, or the HVAC blower motor.

3. Component: ‘5-pin relay assy (20A)’ (3741070-240) – Qty 2

This (Comp 11) is a more complex “changeover” relay. A 5-pin relay has one “common” load pin that can switch between two different “output” pins (one “normally open” and one “normally closed”). This Changeover Logic is used for functions that require switching *between* two circuits, such as a high-beam/low-beam headlight system, or for a power window motor to reverse its direction (up/down). The presence of both types shows the complexity of the Fuse Box Assembly With Relay.

This group is the primary function of the Fuse Box Assembly With Relay. These fuses are sacrificial components designed to fail instantly in an over-current or short-circuit situation, protecting the wiring and the component on that circuit.

The Sacrificial Logic is simple: a small metal filament inside the fuse is designed to melt and break the circuit if the current exceeds its rating (e.g., 10 Amps). This destroys the cheap fuse while saving the expensive wiring harness or electronic module from melting or catching fire.

1. Component: Low-Amperage Fuses (5A, 10A, 15A)

This group (Comp 3, 4, 5) includes ‘5A Blade fuse’ (Qty 29), ’10A Blade fuse’ (Qty 17), and ’15A Blade fuse’ (Qty 8). These are used for low-power circuits. 5A (tan) is often for electronics, instrumentation, and sensor power. 10A (red) is common for lighting circuits, radio, and control modules. 15A (blue) is often used for power sockets (cigarette lighter) and other medium-draw accessories. The large quantity of these shows the complexity of the Fuse Box Assembly With Relay.

2. Component: High-Amperage Fuses (20A, 25A, 30A)

This (Comp 6, 7, 8) includes ’20A Blade fuse’ (Qty 3), ’25A Blade fuse’ (Qty 2), and ’30A Blade fuse’ (Qty 3). These are for high-load circuits. 20A (yellow) might be for the HVAC blower motor, 25A (natural/white) for power windows, and 30A (green) for a main circuit relay. Replacing a blown fuse in the Fuse Box Assembly With Relay with a higher-rated one is extremely dangerous and can cause a fire.

This final group includes the hardware for mounting the Fuse Box Assembly With Relay and servicing its components.

1. Component: ‘Fuse puller’ (171937579) – Qty 1

This (Comp 9) is a small, plastic tool. The Service Logic is that this puller is often clipped inside the cover of the Fuse Box Assembly With Relay. It is designed to safely grip and remove the small blade fuses (Comp 3-8) without the risk of using metal tools (which could cause a short) or damaging the fuses.

2. Component: ‘Cross recessed pan head screw assy’ (Q2360640) – Qty 2

This (Comp 10) is the mounting hardware. These are the bolts that secure the main ‘Fuse box assy (48-circuit)’ (Comp 1) to its mounting bracket in the cab. This ensures the Fuse Box Assembly With Relay is held securely and does not vibrate, which could cause connections to become loose.

The following table provides the complete, detailed breakdown of all 12 component types in the Fuse Box Assembly With Relay for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the Fuse Box Assembly With Relay.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3722010-A01 | Fuse box assy (48-circuit) | 1 |

| 2 | 3711030-240 | 4-pin relay assy (20A) | 9 |

| 3 | 3722011-50 | 5A Blade fuse | 29 |

| 4 | 3722012-50 | 10A Blade fuse | 17 |

| 5 | 3722013-50 | 15A Blade fuse | 8 |

| 6 | 3722014-50 | 20A Blade fuse | 3 |

| 7 | 3722016-50 | 25A Blade fuse | 2 |

| 8 | 3722017-50 | 30A Blade fuse | 3 |

| 9 | 171937579 | Fuse puller | 1 |

| 10 | Q2360640 | Cross recessed pan head screw assy | 2 |

| 11 | 3741070-240 | 5-pin relay assy (20A) | 2 |

| 12 | 3722110-417 | Main relay assy | 1 |

The specifications for the Fuse Box Assembly With Relay are defined by its function as the central power distribution and circuit protection module for the cab’s 24V electrical systems. A well-maintained Fuse Box Assembly With Relay is critical for vehicle reliability.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Fuse Box Assembly With Relay |

| Main Box P/N | 3722010-A01 |

| Capacity | 48-Circuit |

| Main Power Control | ‘Main relay assy’ (3722110-417) |

| Switching Relays (Standard) | 9 x ‘4-pin relay assy (20A)’ (3711030-240) |

| Switching Relays (Changeover) | 2 x ‘5-pin relay assy (20A)’ (3741070-240) |

| Protection Type | Blade Fuses (5A, 10A, 15A, 20A, 25A, 30A) |

| Service Tool | ‘Fuse puller’ (171937579) |

| Total Component Types | 12 |

| Associated System | Cab Electrical Equipment. The Fuse Box Assembly With Relay is the core. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.