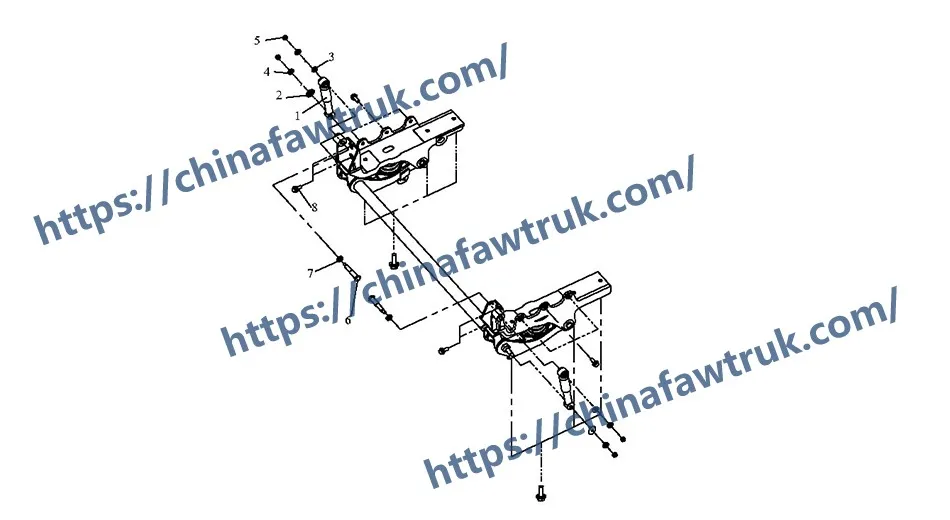

This is a comprehensive technical guide to the Front Suspension Assembly For Cab (Upper, Coil Spring) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide analyzes the 8 serviceable component types that form the critical front damping and mounting system.

The Front Suspension Assembly For Cab is the primary pivot point for the tilt-cab mechanism. Its function is twofold: mechanically, it allows the entire cab structure to tilt forward for easy engine access, and structurally, it provides the primary connection point between the cab and the rigid chassis. This assembly contains crucial rubber damping elements that isolate the driver and interior from the severe vibrations and shocks transmitted through the chassis during heavy-duty operation.

This deconstruction will analyze the key components of the Front Suspension Assembly For Cab, focusing on the damping units, the specialized pivot pins, and the high-strength fasteners that secure the entire structure. Maintaining the integrity of this assembly is vital for driver comfort and safety, as any wear or failure here would lead to excessive cab movement, vibration, and noise, compromising driver control. The proper function of the Front Suspension Assembly For Cab ensures vehicle reliability and operator well-being.

This core group of the Front Suspension Assembly For Cab represents the functional elements responsible for both motion control and articulation.

1. Component: ‘Shock absorber assy – front cab mount’ (5001020-A01-C00) – Qty 2

This (Comp 1) is the main damping unit. The Damping Logic is contained within this assembly, typically using heavy-duty rubber bushings (integrated) or hydraulic elements to isolate the cab. This component must handle the full front weight of the cab and the entire range of motion during tilting. It is the core of the Front Suspension Assembly For Cab.

2. Component: ‘Pivot pin – shock absorber upper fixed point’ (5001028-A01) – Qty 2

This (Comp 6) is the hardened steel pin that connects the hydraulic damper (Comp 1) to the main cab structure or an anchor point. The Pivot Logic requires this pin to be extremely strong and wear-resistant, as the entire cab pivot action for the Front Suspension Assembly For Cab centers on this area.

3. Component: ‘Washer – shock absorber’ (5001021-A01) – Qty 2

This (Comp 2) is a specialized steel washer or retainer. The Limit Stop Logic dictates that this component serves as a mechanical stop or retaining plate for the rubber bushings within the damping assembly. This prevents excessive cab movement, maintaining stability, and protecting the structure of the Front Suspension Assembly For Cab from hard impact.

This group of components provides the necessary clamping force and vibration resistance to secure the Front Suspension Assembly For Cab to the chassis frame.

1. Component: ‘Combination bolt’ (CQ1461230) – Qty 16

This (Comp 8) is the main mounting hardware, a specialized bolt that features a washer permanently attached to its head. The Clamping Logic uses these 16 bolts to secure the entire lower mounting bracket of the Front Suspension Assembly For Cab to the vehicle frame. This is a primary safety connection point.

2. Component: ‘Hex nut’ (CQ34110) – Qty 4

This (Comp 5) is the primary fastening nut. This nut must be a high-strength grade, often used in conjunction with a spring washer (Comp 4, 7) to prevent loosening under the constant vibration the Front Suspension Assembly For Cab experiences.

3. Component: ‘Spring washer’ (Q40310, Q40318) – Qty 4 and 2

This (Comp 4, 7) is a crucial secondary fastener. The Vibration Resistance Logic relies on the spring washer’s ability to provide constant tension to the nut (Comp 5), preventing it from backing off the bolt during operation. This is essential for maintaining the pre-load on the entire Front Suspension Assembly For Cab.

4. Component: ‘Gasket’ (Q40110) – Qty 2

This (Comp 3) is a plain washer or shim. Its function is to distribute the clamping force of the bolt head or nut over a wider surface area of the bracket, protecting the metal surfaces from being damaged by overtightening. This is a small but necessary component of the Front Suspension Assembly For Cab.

The following table provides the complete, detailed breakdown of all 8 component types in the Front Suspension Assembly For Cab (Cab Front Suspension Mount) assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the Front Suspension Assembly For Cab.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5001020-A01-C00 | Shock absorber assy – front cab mount | 2 |

| 2 | 5001021-A01 | Washer – shock absorber (Limit Plate) | 2 |

| 3 | Q40110 | Gasket | 2 |

| 4 | Q40310 | Spring washer | 4 |

| 5 | CQ34110 | Hex nut | 4 |

| 6 | 5001028-A01 | Pivot pin – shock absorber upper fixed point | 2 |

| 7 | Q40318 | Spring washer | 2 |

| 8 | CQ1461230 | Combination bolt | 16 |

The specifications for the Front Suspension Assembly For Cab are defined by its function as a high-strength, dampening mount for the front of the tilt-cab. This assembly is crucial for vertical shock isolation.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Front Suspension Assembly For Cab |

| Primary Logic | Damping mount and pivot for tilt-cab mechanism |

| Core Component P/N | 5001020-A01-C00 |

| Damping Pin P/N | 5001028-A01 |

| Isolation Mechanism | Integrated rubber bushings (Comp 1) and external washers (Comp 3) |

| Safety Component | ‘Washer – shock absorber’ (Limit Plate, 5001021-A01) |

| Mounting Hardware | CQ1461230 Combination bolt / CQ34110 Hex nut |

| Total Component Types | 8 |

| Associated System | Cab Suspension / Tilt System. The Front Suspension Assembly For Cab is the front anchor. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.