Sous-couche insonorisée et calorifuge russe FAW: La barrière thermique qui définit le confort des cabines arctiques

Le Sous-couche Insonorisée Et Isolante Thermique assembly is the foundational layer of the driver’s environment in the FAW J6P CA3250P66K24L1TE5Z dump truck. Designed specifically for the Russian Federation, this multi-component system isolates the cabin interior from the deafening roar of the powertrain and the biting chill of the frozen chassis. By creating a hermetic acoustic and thermal seal, le Sous-couche Insonorisée Et Isolante Thermique transforms the bare metal floor into a habitable workspace capable of sustaining operators through long shifts in sub-zero mining conditions.

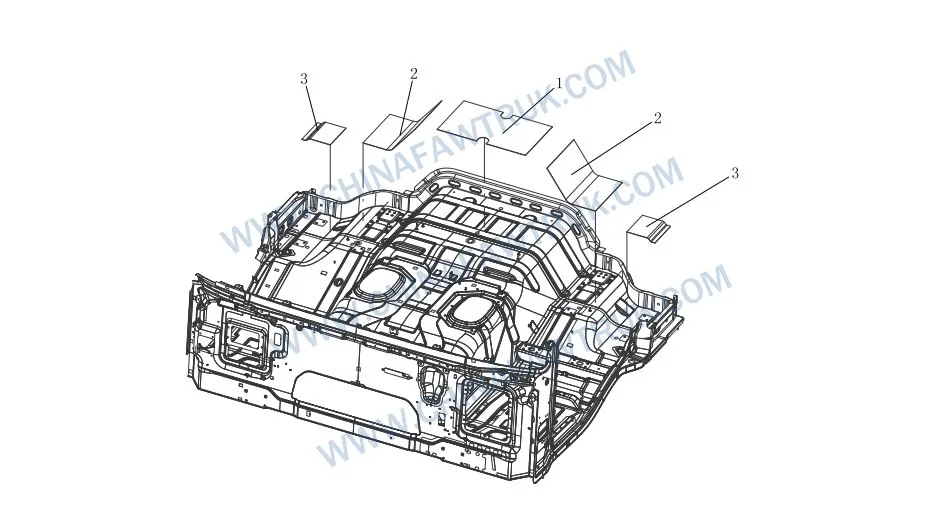

Sous-couche Insonorisée Et Isolante Thermique

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 5109631-B35 | Soundproof and Heat Insulating Pad A | 1 |

| 2 | 5109632-B35 | Soundproof and Heat Insulating Pad B | 2 |

| 3 | 5109633-B35 | Soundproof and Heat Insulating Pad C | 2 |

Acoustic Attenuation and NVH Control

La fonction première du Sous-couche Insonorisée Et Isolante Thermique is to combat the intense Noise, Vibration, et la dureté (Nvh) inherent in heavy diesel operations. The CA3250 dump truck operates with a high-torque engine situated directly beneath the cab floor. Sans l'intervention du Sous-couche Insonorisée Et Isolante Thermique, the steel floor pan would act as a drumhead, amplifying the combustion noise and gear whine into the cabin. This assembly utilizes a multi-density composite structure designed to absorb specific sound frequencies. Le “Pad A” (Partie no. 5109631-B35) typically covers the central transmission tunnel area, which is the loudest zone, utilizing dense mass-loaded vinyl or heavy foam to block airborne noise transmission.

L'efficacité du Sous-couche Insonorisée Et Isolante Thermique lies in its ability to decouple the interior trim from the vibrating metal chassis. By creating a “flottant” couche, the underlay prevents structural vibrations from radiating as audible noise. Le Sous-couche Insonorisée Et Isolante Thermique employs open-cell foam layers to trap sound waves and dissipate them as negligible heat energy. This acoustic damping is critical for reducing driver fatigue; a quieter cabin lowers stress levels and allows for better concentration during long shifts on dangerous mining roads, where situational awareness is vital.

En outre, le Sous-couche Insonorisée Et Isolante Thermique is precision-cut to fit the complex contours of the J6P floor. Gaps in the insulation are acoustic leaks. The specific shapes of “Pad B” (Partie no. 5109632-B35) et “Pad C” (Partie no. 5109633-B35) are engineered to tuck seamlessly under the pedals, sièges, and heater box. This comprehensive coverage ensures that there are no direct pathways for noise to enter the driver’s ear. Le Sous-couche Insonorisée Et Isolante Thermique effectively lowers the interior decibel rating to meet international comfort standards, transforming a rugged workhorse into a professional workspace.

Thermal Dynamics in Arctic Conditions

In the context of the Russian “Zone froide,” the thermal properties of the Sous-couche Insonorisée Et Isolante Thermique are a matter of survival. The steel floor of the truck acts as a massive heat sink, rapidly conducting the warmth of the cabin out to the -40°C ambient air. Le Sous-couche Insonorisée Et Isolante Thermique breaks this thermal bridge. It utilizes materials with extremely low thermal conductivity, such as closed-cell polyethylene foam or fibrous synthetic wool, to trap a layer of dead air against the metal floor. This insulation barrier ensures that the heat generated by the auxiliary heaters remains inside the cab where it is needed.

Inversement, le Sous-couche Insonorisée Et Isolante Thermique also protects the driver from the immense radiant heat generated by the engine and exhaust system located just inches below the floor. During heavy climbing or high-load dumping operations, the under-floor temperatures can soar. Le Sous-couche Insonorisée Et Isolante Thermique agit comme un bouclier thermique, preventing the floor mats from melting and keeping the driver’s footwell at a comfortable temperature. This dual-direction thermal regulation is a unique requirement for heavy trucks, demanding a material that is stable across a temperature delta of over 100 degrees Celsius.

L'installation du Sous-couche Insonorisée Et Isolante Thermique also contributes to the efficiency of the HVAC system. By reducing the thermal load on the heater, the cabin warms up faster during cold starts and maintains temperature with less fuel consumption. Le Sous-couche Insonorisée Et Isolante Thermique minimizes the “cold draft” effect often felt around the ankles in poorly insulated vehicles. For the FAW J6P, maintaining a stable internal climate is essential for preventing window fogging and ensuring the driver’s physical dexterity is not compromised by cold.

Material Science and Environmental Resistance

The material selection for the Sous-couche Insonorisée Et Isolante Thermique dictates its longevity in the harsh Russian environment. The underlay must resist not only temperature extremes but also moisture. Snow and slush tracked into the cab by the driver’s boots will melt and seep through the upper floor mats. Le Sous-couche Insonorisée Et Isolante Thermique is typically manufactured with a hydrophobic (water-repellent) top layer or a closed-cell structure that refuses to absorb water. A sponge-like material would soak up this brine, leading to severe corrosion of the floor pan and the growth of mold and mildew within the cab.

Fire safety is another non-negotiable attribute of the Sous-couche Insonorisée Et Isolante Thermique. Situated close to electrical harnesses and the engine firewall, the material must be self-extinguishing and meet strict flammability standards (such as ISO 3795). The FAW specification ensures that even if an electrical short occurs near the floor, le Sous-couche Insonorisée Et Isolante Thermique will not contribute to the spread of fire. This chemical engineering ensures that the insulation layer is a safety feature, not a hazard.

Durability against compression is also engineered into the Sous-couche Insonorisée Et Isolante Thermique. Over years of service, the constant weight of the driver’s heels and the movement of seats can compress inferior foams, reducing their insulating value. The FAW components (5109631-B35, 5109632-B35, 5109633-B35) utilize high-density rebound foam that maintains its thickness and structural integrity over time. This resilience ensures that the Sous-couche Insonorisée Et Isolante Thermique continues to provide peak acoustic and thermal performance throughout the vehicle’s lifespan.

Stratégie d'inspection et de remplacement

Alors que le Sous-couche Insonorisée Et Isolante Thermique is a passive component, it requires inspection, especially in older vehicles. Fleet managers should check under the floor mats during annual services for signs of dampness. A wet Sous-couche Insonorisée Et Isolante Thermique is an indicator of a cab leak (windshield seal or door gasket) that needs immediate attention. If the underlay is saturated with oil or diesel from a spill, it loses its insulating properties and becomes a fire risk; in such cases, immediate replacement is required.

Remplacer le Sous-couche Insonorisée Et Isolante Thermique is a labor-intensive but straightforward process. It typically involves removing the seats and lower trim panels. Because the assembly is segmented into parts A, B, et C, technicians can replace only the damaged section. Par exemple, the driver’s side pad (often Pad B or C) sees the most wear and fluid exposure. La conception modulaire du Sous-couche Insonorisée Et Isolante Thermique reduces maintenance costs by allowing for partial refurbishment of the floor insulation.

It is crucial to use genuine FAW replacement parts for the Sous-couche Insonorisée Et Isolante Thermique. Universal insulation rolls often lack the precise cutouts for seat bolts, gear levers, and heater vents. Poorly fitted insulation can bunch up, interfering with pedal operation—a serious safety hazard. Le véritable Sous-couche Insonorisée Et Isolante Thermique drops perfectly into place, ensuring complete coverage without obstructing vehicle controls, restoring the cabin to its factory-spec quietness and warmth.

Conclusion: The Silent Guardian of Comfort

Le Sous-couche Insonorisée Et Isolante Thermique est une critique, albeit hidden, component of the FAW J6P’s driver environment. Comprenant 5 distinct pieces across three part numbers, it forms a comprehensive shield against the harsh realities of the Russian climate and the mechanical noise of the truck. Its role in maintaining thermal stability and acoustic comfort directly impacts driver performance and safety.

Pour les exploitants de flotte, l'état du Sous-couche Insonorisée Et Isolante Thermique should not be overlooked. A dry, intact underlay protects the floor pan from corrosion and keeps the driver alert. By maintaining this barrier and using genuine replacements, operators ensure that their vehicles remain comfortable, efficient workplaces, capable of enduring the extreme challenges of the Russian heavy transport sector.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.