Sous-couche d'isolation de sol russe FAW: Une barrière thermique à trois segments conçue pour un contrôle climatique extrême

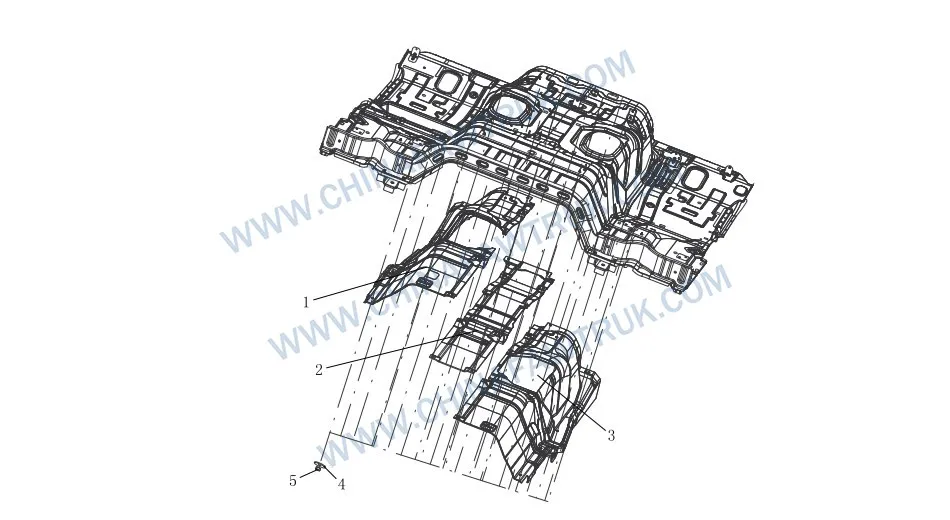

Le Sous-couche d'isolation de sol russe FAW assembly is the primary thermal defense system for the cabin floor of the CA3250P66K24L1TE5Z dump truck. In the severe operational theater of the Russian Federation, the metal floor pan acts as a massive thermal bridge, conducting the freezing ambient temperatures of the chassis directly into the driver’s workspace. Simultanément, it must shield the interior from the intense radiant heat generated by the transmission and exhaust systems located immediately below. This specialized Sous-couche d'isolation de sol russe FAW utilizes a three-piece segmented design to provide comprehensive coverage, ensuring that the cabin maintains a stable, habitable temperature regardless of the external environment.

Sous-couche d'isolation de sol russe FAW

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 5109311-B35 | Floor Heat Insulation Pad Left | 1 |

| 2 | 5109313-B35 | Floor Heat Insulation Pad Middle | 1 |

| 3 | 5109312-B35 | Floor Heat Insulation Pad Right | 1 |

| 4 | 5109318-A01 | Machine à laver – Floor Heat Insulation Pad | 25 |

| 5 | CQ34006 | Écrou hexagonal | 25 |

Thermodynamic Efficiency and Cabin Climate Logic

La philosophie de conception derrière le Sous-couche d'isolation de sol russe FAW prioritizes the creation of a “coupure thermique” between the exterior metal shell and the interior cabin space. In the extreme latitudes of the Russian North, the temperature differential between the cabin interior (heated to +20°C) and the exterior chassis (dropping to -40°C) creates a massive gradient. Sans le Sous-couche d'isolation de sol russe FAW, the steel floor pan acts as a heat sink, rapidly conducting precious cabin heat out into the atmosphere. This not only forces the auxiliary heaters to run continuously, consuming excess fuel, but also creates uncomfortable cold drafts around the driver’s feet, which can lead to reduced reaction times and discomfort during long shifts.

Le Sous-couche d'isolation de sol russe FAW assembly employs a high-density, multi-layer composite material. The core layer typically consists of a closed-cell foam or fibrous wool that traps dead air, the most effective natural insulator. This structure prevents conductive heat loss. En outre, le matériau utilisé dans le Sous-couche d'isolation de sol russe FAW features heat-reflective properties on its underside. This is crucial for managing the radiant heat generated by the transmission housing and exhaust downpipe, which run directly beneath the floor tunnel. By reflecting this heat away, the underlay prevents the floor tunnel from becoming uncomfortably hot during heavy uphill hauls, maintaining a balanced internal climate.

Le “B35” suffix in the part numbers for the Sous-couche d'isolation de sol russe FAW components indicates a specification tailored for the J6P cab’s specific floor geometry in the cold-zone configuration. This tailored fit ensures that there are no gaps where thermal leakage can occur. Le Sous-couche d'isolation de sol russe FAW is molded to contour tightly around the gearbox tunnel, seat risers, and pedal box. Any gap in this insulation barrier would act as a “thermal chimney,” sucking warm air out and pulling freezing air in. The precision molding of the FAW components eliminates these weak points, ensuring maximum thermal efficiency.

The Tri-Segmented Architectural Advantage

Une caractéristique clé du Sous-couche d'isolation de sol russe FAW is its segmentation into three distinct parts: le Floor Heat Insulation Pad Left (Partie no. 5109311-B35), le Floor Heat Insulation Pad Middle (Partie no. 5109313-B35), et le Floor Heat Insulation Pad Right (Partie no. 5109312-B35). This modular design is not arbitrary; it is a strategic engineering choice for serviceability. The middle pad, covering the transmission tunnel, is the most likely to require removal for gearbox access or shift linkage maintenance. By separating it from the side pads, le Sous-couche d'isolation de sol russe FAW allows mechanics to expose the tunnel access plate without dismantling the entire driver or passenger side floor covering.

Le Floor Heat Insulation Pad Left is shaped to accommodate the steering column, pedal box, and driver’s seat mounts. This section of the Sous-couche d'isolation de sol russe FAW endures the most wear and tear from the driver’s heels. Its segregation means that if the driver’s side pad becomes worn or damaged by heavy winter boots, it can be replaced individually, saving the cost of a full floor replacement. De la même manière, le Floor Heat Insulation Pad Right is contoured for the passenger footwell and auxiliary heater vents. This modularity reduces long-term ownership costs and simplifies logistics for fleet parts departments.

The interface between these three sections of the Sous-couche d'isolation de sol russe FAW is designed with overlap zones. When installed, the middle pad typically overlaps the edges of the left and right pads (or vice versa, depending on the specific layering sequence), creating a continuous barrier. This shingled design prevents liquids—such as melted snow from boots or spilled drinks—from seeping between the pads and reaching the metal floor, where it could cause unseen corrosion. Le Sous-couche d'isolation de sol russe FAW thus acts as a secondary moisture barrier, protecting the structural integrity of the cab floor.

High-Density Fastening for NVH Control

L'installation du Sous-couche d'isolation de sol russe FAW is secured by a remarkably high number of fasteners, specifically 25 unités du Machine à laver – Floor Heat Insulation Pad (Partie no. 5109318-A01) et 25 unités du Écrou hexagonal (Partie no. CQ34006). This high density of fastening points is critical for Noise, Vibration, et la dureté (Nvh) contrôle. A loose insulation pad on a vibrating diesel truck floor acts like a drum skin, potentially amplifying chassis noise rather than dampening it. By pinning the Sous-couche d'isolation de sol russe FAW tightly to the floor pan at multiple points, the assembly effectively adds mass and damping to the steel panels, reducing structural resonance.

The specialized washer, Machine à laver – Floor Heat Insulation Pad, is designed with a wide surface area. This is essential for distributing the clamping force of the nut over the soft, compressible material of the Sous-couche d'isolation de sol russe FAW. A standard small washer would simply sink into the insulation, tearing the material and failing to provide a secure hold. The specialized washer ensures that the underlay is compressed uniformly, maintaining its position and preventing it from bunching up or interfering with the pedals—a critical safety consideration.

En outre, the secure fastening of the Sous-couche d'isolation de sol russe FAW prevents it from chafing against the metal floor. Dans un environnement à fortes vibrations, any movement between the insulation and the painted metal can sand away the paint, menant à la rouille. By rigidly securing the pads with the 25 nut-and-washer combinations, le Sous-couche d'isolation de sol russe FAW becomes an integral part of the floor structure, protecting the paintwork beneath it from abrasion while performing its thermal duties.

Entretien, Inspection, and Replacement

Alors que le Sous-couche d'isolation de sol russe FAW is a passive component, it requires inspection to ensure the long-term health of the vehicle. The primary enemy of floor insulation is moisture saturation. If the door seals leak or if the windshield bond fails, water can accumulate in the underlay. A wet Sous-couche d'isolation de sol russe FAW loses its thermal properties and becomes a breeding ground for mold and rust. During annual maintenance, mechanics should lift the edge of the mats to check for dampness. If the underlay is soaked with water, huile, ou du gasoil, it must be replaced immediately to prevent fire hazards and corrosion.

Replacement of the Sous-couche d'isolation de sol russe FAW is a straightforward but labor-intensive process, usually requiring the removal of the seats and lower interior trim. Because the assembly relies on stud-welded bolts on the floor pan, care must be taken when removing the 25 Écrou hexagonal attaches. If a nut is seized due to corrosion, snapping the stud requires welding a new one to the floor, significantly complicating the repair. Using penetrating oil on these nuts before removal is a recommended practice when servicing the Sous-couche d'isolation de sol russe FAW.

Fleet managers should ensure that only genuine FAW parts are used for replacement. Generic bulk insulation materials lack the precise molding, the cutout locations for seat bolts, and the heat-reflective backing of the genuine Sous-couche d'isolation de sol russe FAW. Poorly fitted aftermarket insulation can interfere with the accelerator or brake pedals, creating a serious safety risk. The genuine pads drop into place perfectly, ensuring that the cabin remains the safe, chaud, and quiet environment it was designed to be.

Conclusion: The Foundation of Arctic Survivability

Le Sous-couche d'isolation de sol russe FAW assembly is a vital component in the CA3250 dump truck’s arsenal against the elements. Comprenant 5 main parts and 50 pieces of fastening hardware, it forms a comprehensive barrier that manages heat, son, et vibrations. Its segmented design allows for practical maintenance, while its material engineering ensures the driver remains isolated from the harsh reality of the Russian winter.

Pour les exploitants de flotte, l'état du Sous-couche d'isolation de sol russe FAW is a direct indicator of cabin integrity. A dry, well-secured underlay protects the vehicle structure and enhances operator efficiency. By prioritizing the maintenance of this thermal shield, operators ensure that their workforce can perform safely and comfortably, maximizing the productivity of the fleet in even the most extreme conditions.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.