Bienvenue dans ce guide technique critique sur le Turbocompresseur FAW (Partie no. 1118010-91W-C00), the single most important power-adder component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This is the heart of the engine’s forced induction system.

Le Turbocompresseur FAW is responsible for forcing a high volume of compressed air into the engine’s cylinders, allowing for a much larger fuel burn, which dramatically increases horsepower and torque. This component is a precision-engineered turbine that spins at speeds exceeding 150,000 RPM.

Ce guide est une ressource essentielle pour les techniciens professionnels, engine specialists, et gestionnaires de pièces. Nous déconstruirons l'ensemble Turbocompresseur FAW assembly and its critical ancillary systems, including the high-temperature mounting, the high-pressure oil feed, and the oil return lines, down to the smallest serviceable unit.

The core component is the ‘Turbine Turbocharger Assembly’ (1118010-91W-C00). C'est le principal Turbocompresseur FAW unité. It is a highly-balanced, precision assembly consisting of two main halves: le “hot side” et le “cold side.”

**The Turbine (Hot Side):** The engine’s hot exhaust gases are funneled directly into the turbine housing. This high-pressure gas spins a turbine wheel, which is made from an exotic, high-temperature superalloy like Inconel, capable of withstanding over 900°C (1650° F). C'est le “moteur” that powers the entire Turbocompresseur FAW.

**The Compressor (Cold Side):** The turbine wheel is connected via a hardened steel shaft to a “compressor wheel” on the cold side. This wheel is typically milled from a solid billet of aluminum. Pendant qu'il tourne, it draws in fresh, filtered air and compresses it (créer “booster”), forcing it into the engine’s intercooler and intake manifold.

**The CHRA (Center Hub Rotating Assembly):** The shaft connecting these two wheels spins at incredible speeds in a “flottant” journal bearing system. Ce roulement, at the heart of the Turbocompresseur FAW, does not physically touch the shaft; it rides on a microscopic film of high-pressure engine oil, which both lubricates and cools it. The integrity of this oil film is the single most important factor in Turbocompresseur FAW longévité.

Montage du Turbocompresseur FAW is an extreme-heat challenge. It bolts directly to the exhaust manifold, which is the hottest part of the engine. Pour gérer ça, the system relies on specialized hardware. The four ‘Turbocharger double-headed stud bolts’ (1118051-53D) are threaded into the exhaust manifold first. These are made of high-tensile, heat-resistant steel.

The ‘Turbocharger gasket’ (1118013A81D) is placed onto these studs. This is not a paper gasket; it is a Multi-Layer Steel (MLS) joint, designed to be crushed between the manifold and the Turbocompresseur FAW turbine housing. It must contain the high-pressure, superheated exhaust gases, prévenir les fuites. A leaking turbine inlet gasket will “siffler” and cause a severe loss of boost pressure.

Le Turbocompresseur FAW is then slid onto the studs, followed by the four ‘Sleeve – turbocompresseur’ (1118014-53D). These sleeves are critical; they act as precision spacers and, plus important encore, thermal isolators, helping to keep the nuts from absorbing the full heat of the turbine housing. Enfin, the four ‘Nut – turbocompresseur’ (1118073-29D) are torqued down. These are special “contre-écrous,” often made of distortion-locking steel, designed to resist loosening under extreme heat cycles and vibration. This entire set of hardware is essential for a reliable Turbocompresseur FAW installation.

UN Turbocompresseur FAW tournant à 150,000 RPM will be destroyed in less than five seconds without oil. The ‘Turbocharger oil inlet pipe assembly’ (1118060-91W) is its lifeline. This is a pre-formed, rigid steel pipe designed to tap into a high-pressure oil gallery on the engine block.

This pipe feeds the coolest, cleanest, highest-pressure oil directly to the CHRA’s journal bearing. The design of this Turbocompresseur FAW oil feed is critical; it must be free of kinks, fissure, or any debris.

This high-pressure connection is sealed using specialized banjo fittings. The ‘Banjo bolt’ (Q/XC3451.1M16X1.5) is a hollow bolt that allows oil to flow through it. It is sealed by the two ‘Gaskets’ (Q / WC3403-94(16X22)). These are soft copper or aluminum crush washers. One gasket is placed on each side of the banjo fitting. When the bolt is torqued, these washers deform, creating a perfect, joint haute pression. These gaskets are single-use. Re-using them will cause a high-pressure oil leak, starving the Turbocompresseur FAW and creating a massive fire risk as oil sprays onto the red-hot turbine housing. This is a critical service point for the Turbocompresseur FAW.

After the oil is forced through the Turbocompresseur FAW palier, it is no longer under pressure. It must then drain *out* of the CHRA and back to the oil pan. This is the job of the ‘Turbocharger oil return pipe assembly’ (1118080-2000).

This is a large-diameter, low-pressure pipe. Its design is critical: it must be as wide as possible and routed with a constant, downward slope (gravity feed). Any kink, clog, or low spot in this return line will cause the oil to back up inside the Turbocompresseur FAW‘s center housing.

When this backup occurs, the built-up oil pressure has nowhere to go but past the Turbocompresseur FAW‘s internal “piston ring” scellés. This is a primary cause of “fumée bleue” from the exhaust, as oil is forced into the hot turbine housing and burned. It can also force oil into the “cold side,” fouling the intercooler. The ‘Clamp – turbocharger oil return pipe’ (1118083-81D) is used to secure this pipe.

This return pipe is sealed at the Turbocompresseur FAW housing by the ‘Gasket – turbocharger oil return pipe’ (1118094-29D), and at the engine block by the ‘Hydraulic pneumatic O-ring rubber seal’ (Q07343236C). Both seals are critical to prevent external leaks. This entire return path is a key part of the Turbocompresseur FAW system’s health.

The ‘Turbocharger heat shield’ (1118031-1509) is a stamped metal plate. Its function is to sit between the red-hot turbine housing and the “froid” compressor housing, or between the turbine and the engine block. It blocks the intense radiant heat from the “hot side” de la Turbocompresseur FAW.

This shield prevents this extreme heat from “coking” (burning) the oil inside the center bearing housing after the engine is shut off. Ce “bain de chaleur” is a major cause of Turbocompresseur FAW échec. This shield, along with other miscellaneous fasteners like the ‘Hex flange bolts’ (Q1840830, Q1840812, Q1840612, Q1840816), is used to secure the various pipes, pinces, and shields, ensuring the entire Turbocompresseur FAW assembly is free from vibration and protected from its own heat.

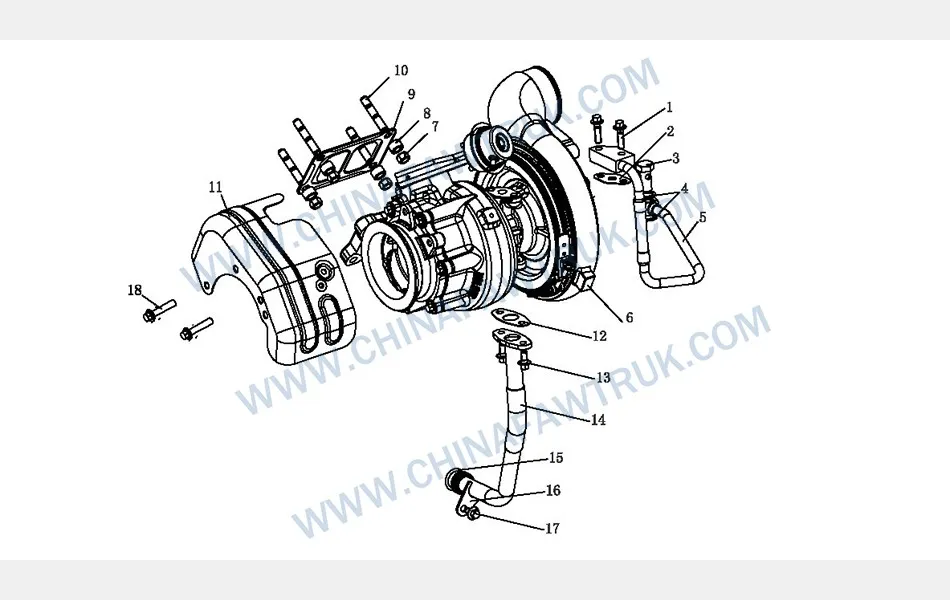

Le tableau suivant fournit l'intégralité, detailed breakdown of all components identified in the ‘Turbocharger’ schéma du tracteur FAW CA4251P66K24T1A3E5. Un service complet du Turbocompresseur FAW requires all new gaskets, o-rings, and studs.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | Q1840830 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

| 2 | 1118063-D6 | Joint – oil inlet pipe | 1 |

| 3 | Q/XC3451.1M16X1.5 | Banjo bolt | 1 |

| 4 | Q / WC3403-94(16X22) | Joint | 2 |

| 5 | 1118060-91W | Turbocharger oil inlet pipe assembly (selon l'échantillon) | 1 |

| 6 | 1118010-91W-C00 | Turbine Turbocharger Assembly | 1 |

| 7 | 1118073-29D | Noix – turbocompresseur | 4 |

| 8 | 1118014-53D | Manche – turbocompresseur | 4 |

| 9 | 1118013A81D | Turbocharger gasket | 1 |

| 10 | 1118051-53D | Turbocharger double-headed stud bolt | 4 |

| 11 | 1118031-1509 | Turbocharger heat shield | 1 |

| 12 | 1118094-29D | Joint – turbocharger oil return pipe | 1 |

| 13 | Q1840812 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 1 |

| 14 | 1118080-2000 | Turbocharger oil return pipe assembly | 1 |

| 15 | Q07343236C | Joint torique pneumatique hydraulique en caoutchouc | 1 |

| 16 | 1118083-81D | Serrer – turbocharger oil return pipe | 1 |

| 17 | Q1840612 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 1 |

| 18 | Q1840816 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

Les spécifications pour le Turbocompresseur FAW are defined by its high-speed, high-temperature operation, requiring a robust system for mounting, lubrification, and heat shielding. L'ensemble Turbocompresseur FAW assembly is a precision-balanced unit.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Turbocompresseur FAW |

| Assemblage principal P/N | 1118010-91W-C00 |

| Bearing System | Floating Journal Bearing (Oil Lubricated & Cooled) |

| Système de montage | 4-Goujon (1118051-53D) with Nuts (1118073-29D) & Joint (1118013A81D) |

| Oil Feed System | High-Pressure Inlet Pipe (1118060-91W) w/ Banjo Seals (Q / WC3403-94) |

| Oil Return System | Low-Pressure Gravity-Feed Pipe (1118080-2000) w/ Gasket (1118094-29D) |

| Gestion thermique | 1x Turbocharger Heat Shield (1118031-1509), 4x Sleeves (1118014-53D) | Manche

| Fonction principale | Uses exhaust gas energy to compress intake air (forced induction), increasing engine power and efficiency. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.