Добро пожаловать в это важное техническое руководство по ФАВ Турбокомпрессор (Часть №. 1118010-91W-C00), the single most important power-adder component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. This is the heart of the engine’s forced induction system.

The ФАВ Турбокомпрессор is responsible for forcing a high volume of compressed air into the engine’s cylinders, allowing for a much larger fuel burn, which dramatically increases horsepower and torque. This component is a precision-engineered turbine that spins at speeds exceeding 150,000 об/мин.

Это руководство является важным ресурсом для профессиональных технических специалистов., специалисты по двигателям, и менеджеры по запчастям. Мы разберем всю ФАВ Турбокомпрессор assembly and its critical ancillary systems, including the high-temperature mounting, the high-pressure oil feed, and the oil return lines, вплоть до наименьшей исправной единицы.

The core component is the ‘Turbine Turbocharger Assembly’ (1118010-91W-C00). Это основной ФАВ Турбокомпрессор единица. It is a highly-balanced, precision assembly consisting of two main halves: а “горячая сторона” и “cold side.”

**The Turbine (Горячая сторона):** The engine’s hot exhaust gases are funneled directly into the turbine housing. This high-pressure gas spins a turbine wheel, which is made from an exotic, high-temperature superalloy like Inconel, capable of withstanding over 900°C (1650° F.). Это “двигатель” that powers the entire ФАВ Турбокомпрессор.

**The Compressor (Холодная сторона):** The turbine wheel is connected via a hardened steel shaft to a “колесо компрессора” на холодной стороне. This wheel is typically milled from a solid billet of aluminum. Когда он вращается, it draws in fresh, filtered air and compresses it (создание “способствовать росту”), forcing it into the engine’s intercooler and intake manifold.

**The CHRA (Center Hub Rotating Assembly):** The shaft connecting these two wheels spins at incredible speeds in a “плавающий” journal bearing system. Этот подшипник, at the heart of the ФАВ Турбокомпрессор, does not physically touch the shaft; it rides on a microscopic film of high-pressure engine oil, which both lubricates and cools it. The integrity of this oil film is the single most important factor in ФАВ Турбокомпрессор долговечность.

Монтаж ФАВ Турбокомпрессор is an extreme-heat challenge. It bolts directly to the exhaust manifold, which is the hottest part of the engine. To handle this, the system relies on specialized hardware. The four ‘Turbocharger double-headed stud bolts’ (1118051-53Д) are threaded into the exhaust manifold first. These are made of high-tensile, heat-resistant steel.

The ‘Turbocharger gasket’ (1118013A81D) is placed onto these studs. This is not a paper gasket; it is a Multi-Layer Steel (МЛС) прокладка, designed to be crushed between the manifold and the ФАВ Турбокомпрессор turbine housing. It must contain the high-pressure, superheated exhaust gases, предотвращение утечек. A leaking turbine inlet gasket will “свист” and cause a severe loss of boost pressure.

The ФАВ Турбокомпрессор is then slid onto the studs, followed by the four ‘Sleeve – турбокомпрессор’ (1118014-53Д). These sleeves are critical; they act as precision spacers and, что еще более важно, thermal isolators, helping to keep the nuts from absorbing the full heat of the turbine housing. Окончательно, the four ‘Nut – турбокомпрессор’ (1118073-29Д) are torqued down. These are special “контргайки,” often made of distortion-locking steel, designed to resist loosening under extreme heat cycles and vibration. This entire set of hardware is essential for a reliable ФАВ Турбокомпрессор установка.

А ФАВ Турбокомпрессор вращаясь в 150,000 RPM will be destroyed in less than five seconds without oil. The ‘Turbocharger oil inlet pipe assembly’ (1118060-91Вт) is its lifeline. This is a pre-formed, rigid steel pipe designed to tap into a high-pressure oil gallery on the engine block.

This pipe feeds the coolest, cleanest, highest-pressure oil directly to the CHRA’s journal bearing. The design of this ФАВ Турбокомпрессор oil feed is critical; it must be free of kinks, трещины, or any debris.

This high-pressure connection is sealed using specialized banjo fittings. The ‘Banjo bolt’ (Q/XC3451.1 M16X1.5) is a hollow bolt that allows oil to flow through it. It is sealed by the two ‘Gaskets’ (Q/WC3403-94(16Х22)). These are soft copper or aluminum crush washers. One gasket is placed on each side of the banjo fitting. When the bolt is torqued, these washers deform, создание идеального, high-pressure seal. These gaskets are single-use. Re-using them will cause a high-pressure oil leak, starving the ФАВ Турбокомпрессор and creating a massive fire risk as oil sprays onto the red-hot turbine housing. This is a critical service point for the ФАВ Турбокомпрессор.

After the oil is forced through the ФАВ Турбокомпрессор несущий, it is no longer under pressure. It must then drain *out* of the CHRA and back to the oil pan. This is the job of the ‘Turbocharger oil return pipe assembly’ (1118080-2000).

This is a large-diameter, low-pressure pipe. Its design is critical: it must be as wide as possible and routed with a constant, downward slope (gravity feed). Any kink, clog, or low spot in this return line will cause the oil to back up inside the ФАВ Турбокомпрессор‘s center housing.

When this backup occurs, the built-up oil pressure has nowhere to go but past the ФАВ Турбокомпрессор‘s internal “piston ring” уплотнения. This is a primary cause of “синий дым” from the exhaust, as oil is forced into the hot turbine housing and burned. It can also force oil into the “холодная сторона,” fouling the intercooler. The ‘Clamp – turbocharger oil return pipe’ (1118083-81Д) is used to secure this pipe.

This return pipe is sealed at the ФАВ Турбокомпрессор housing by the ‘Gasket – turbocharger oil return pipe’ (1118094-29Д), and at the engine block by the ‘Hydraulic pneumatic O-ring rubber seal’ (Q07343236C). Both seals are critical to prevent external leaks. This entire return path is a key part of the ФАВ Турбокомпрессор system’s health.

The ‘Turbocharger heat shield’ (1118031-1509) is a stamped metal plate. Its function is to sit between the red-hot turbine housing and the “холодный” compressor housing, or between the turbine and the engine block. It blocks the intense radiant heat from the “горячая сторона” принадлежащий ФАВ Турбокомпрессор.

This shield prevents this extreme heat from “coking” (burning) the oil inside the center bearing housing after the engine is shut off. Этот “тепловая выдержка” is a major cause of ФАВ Турбокомпрессор отказ. This shield, along with other miscellaneous fasteners like the ‘Hex flange bolts’ (Q1840830, Q1840812, Q1840612, Q1840816), is used to secure the various pipes, зажимы, and shields, ensuring the entire ФАВ Турбокомпрессор assembly is free from vibration and protected from its own heat.

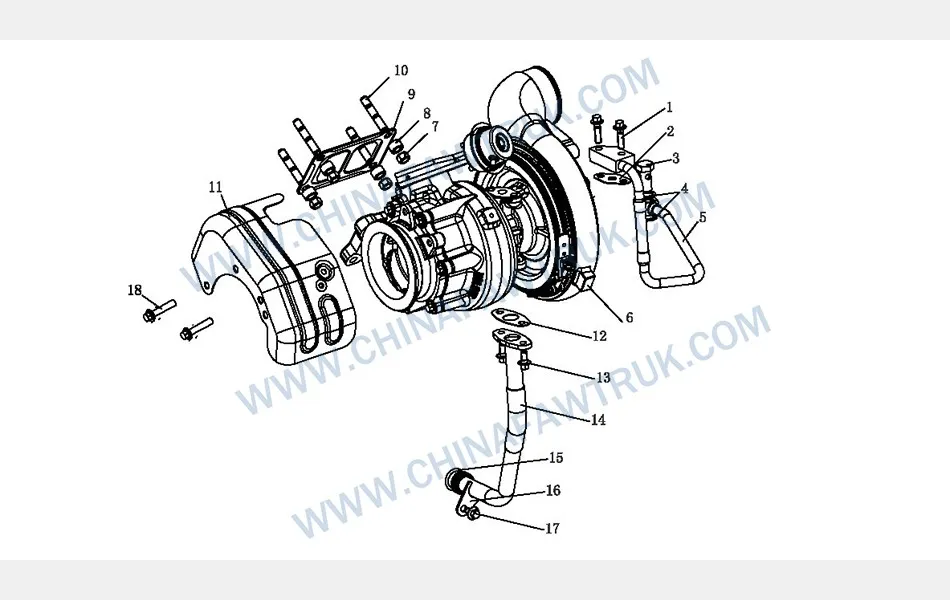

В следующей таблице представлена полная, detailed breakdown of all components identified in the ‘Turbocharger’ схема трактора FAW CA4251P66K24T1A3E5. Полное обслуживание ФАВ Турбокомпрессор requires all new gaskets, o-rings, and studs.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | Q1840830 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 2 |

| 2 | 1118063-D6 | Прокладка – впускная трубка масла | 1 |

| 3 | Q/XC3451.1 M16X1.5 | Банджо-болт | 1 |

| 4 | Q/WC3403-94(16Х22) | Прокладка | 2 |

| 5 | 1118060-91Вт | Turbocharger oil inlet pipe assembly (по образцу) | 1 |

| 6 | 1118010-91W-C00 | Turbine Turbocharger Assembly | 1 |

| 7 | 1118073-29Д | Орех – турбокомпрессор | 4 |

| 8 | 1118014-53Д | Рукав – турбокомпрессор | 4 |

| 9 | 1118013A81D | Turbocharger gasket | 1 |

| 10 | 1118051-53Д | Turbocharger double-headed stud bolt | 4 |

| 11 | 1118031-1509 | Turbocharger heat shield | 1 |

| 12 | 1118094-29Д | Прокладка – turbocharger oil return pipe | 1 |

| 13 | Q1840812 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 1 |

| 14 | 1118080-2000 | Turbocharger oil return pipe assembly | 1 |

| 15 | Q07343236C | Гидравлическое пневматическое резиновое уплотнительное кольцо | 1 |

| 16 | 1118083-81Д | Зажим – turbocharger oil return pipe | 1 |

| 17 | Q1840612 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 1 |

| 18 | Q1840816 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 2 |

Технические характеристики ФАВ Турбокомпрессор are defined by its high-speed, high-temperature operation, requiring a robust system for mounting, смазка, and heat shielding. Весь ФАВ Турбокомпрессор assembly is a precision-balanced unit.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | ФАВ Турбокомпрессор |

| Артикул основного узла | 1118010-91W-C00 |

| Подшипниковая система | Floating Journal Bearing (Oil Lubricated & Cooled) |

| Система крепления | 4-Шпилька (1118051-53Д) with Nuts (1118073-29Д) & Прокладка (1118013A81D) |

| Oil Feed System | High-Pressure Inlet Pipe (1118060-91Вт) w/ Banjo Seals (Q/WC3403-94) |

| Oil Return System | Low-Pressure Gravity-Feed Pipe (1118080-2000) w/ Gasket (1118094-29Д) |

| Управление температурным режимом | 1x Turbocharger Heat Shield (1118031-1509), 4x Sleeves (1118014-53Д) | Рукав

| Основная функция | Uses exhaust gas energy to compress intake air (принудительная индукция), increasing engine power and efficiency. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..