مرحبًا بك في هذا الدليل الفني المهم حول الشاحن التربيني فاو (الجزء لا. 1118010-91W-C00), أهم مكون للطاقة في FAW Jiefang CA4251P66K24T1A3E5 6×4 جرار نصف مقطورة ديزل. هذا هو قلب نظام الحث القسري للمحرك.

ال الشاحن التربيني فاو هو المسؤول عن دفع كمية كبيرة من الهواء المضغوط إلى أسطوانات المحرك, مما يسمح بحرق وقود أكبر بكثير, مما يزيد بشكل كبير من القوة الحصانية وعزم الدوران. هذا المكون عبارة عن توربين مصمم بدقة ويدور بسرعات تتجاوز 150,000 دورة في الدقيقة.

يعد هذا الدليل موردًا أساسيًا للفنيين المحترفين, متخصصون في المحرك, ومديري قطع الغيار. سنقوم بتفكيك الكل الشاحن التربيني فاو التجميع وأنظمته المساعدة الهامة, بما في ذلك تركيب درجة الحرارة العالية, تغذية الزيت عالي الضغط, وخطوط عودة النفط, وصولاً إلى أصغر وحدة صالحة للخدمة.

المكون الأساسي هو "مجموعة الشاحن التوربيني التوربيني".’ (1118010-91W-C00). هذا هو الشيء الرئيسي الشاحن التربيني فاو وحدة. إنها متوازنة للغاية, تجميع دقيق يتكون من نصفين رئيسيين: ال “الجانب الساخن” و “الجانب البارد.”

**التوربين (الجانب الساخن):** يتم توجيه غازات العادم الساخنة للمحرك مباشرة إلى غلاف التوربين. يقوم هذا الغاز ذو الضغط العالي بتدوير عجلة التوربينات, وهو مصنوع من الغريبة, السبائك الفائقة ذات درجة الحرارة العالية مثل Inconel, قادرة على تحمل أكثر من 900 درجة مئوية (1650° f). هذا هو “محرك” الذي يقوي كامل الشاحن التربيني فاو.

**الضاغط (الجانب البارد):** يتم توصيل عجلة التوربين عبر عمود فولاذي مقوى بـ “عجلة الضاغط” على الجانب البارد. عادة ما يتم طحن هذه العجلة من قطعة صلبة من الألومنيوم. كما يدور, يجذب طازجًا, الهواء المصفى وضغطه (خلق “يعزز”), إجباره على الدخول إلى المبرد الداخلي للمحرك ومشعب السحب.

**CHRA (مركز المحور الدورية الجمعية):** يدور العمود الذي يربط هاتين العجلتين بسرعات مذهلة في “عائم” نظام تحمل المجلة. هذا المحمل, في قلب الشاحن التربيني فاو, لا يلمس العمود جسديًا; فهو يركب على طبقة مجهرية من زيت المحرك عالي الضغط, الذي يقوم بتشحيمه وتبريده. تعد سلامة هذا الفيلم الزيتي العامل الأكثر أهمية في الشاحن التربيني فاو طول العمر.

تركيب الشاحن التربيني فاو يمثل تحديًا شديد الحرارة. يتم تثبيته مباشرة على مشعب العادم, وهو الجزء الأكثر سخونة في المحرك. للتعامل مع هذا, يعتمد النظام على الأجهزة المتخصصة. المسامير الأربعة ذات الرأس المزدوج للشاحن التوربيني’ (1118051-53د) يتم ربطها في مشعب العادم أولاً. هذه مصنوعة من الشد العالي, فولاذ مقاوم للحرارة.

حشية الشاحن التوربيني’ (1118013A81D) يتم وضعها على هذه الأزرار. هذه ليست حشية ورقية; إنه فولاذ متعدد الطبقات (متعدد الأطراف) طوقا, مصممة ليتم سحقها بين المشعب و الشاحن التربيني فاو السكن التوربيني. يجب أن تحتوي على الضغط العالي, غازات العادم شديدة الحرارة, منع التسربات. سوف تتسرب حشية مدخل التوربين “صافرة” ويسبب خسارة فادحة في الضغط المعزز.

ال الشاحن التربيني فاو ثم ينزلق على الأزرار, تليها "الأكمام الأربعة". – الشاحن التوربيني’ (1118014-53د). هذه الأكمام حاسمة; أنها بمثابة الفواصل الدقيقة و, والأهم من ذلك, العوازل الحرارية, مما يساعد على منع المكسرات من امتصاص الحرارة الكاملة لسكن التوربين. أخيراً, الأربعة "الجوز." – الشاحن التوربيني’ (1118073-29د) يتم عزم الدوران إلى أسفل. هذه خاصة “قفل المكسرات,” غالبًا ما تكون مصنوعة من الفولاذ المقاوم للتشويه, مصممة لمقاومة الارتخاء في ظل دورات الحرارة الشديدة والاهتزاز. تعتبر هذه المجموعة الكاملة من الأجهزة ضرورية للحصول على موثوقية الشاحن التربيني فاو تثبيت.

أ الشاحن التربيني فاو الغزل عند 150,000 سيتم تدمير عدد الدورات في الدقيقة في أقل من خمس ثوانٍ بدون زيت. مجموعة أنابيب مدخل زيت الشاحن التوربيني’ (1118060-91دبليو) هو شريان الحياة. هذا هو تشكيلها مسبقا, أنبوب فولاذي صلب مصمم للاستفادة من معرض الزيت عالي الضغط الموجود في كتلة المحرك.

هذا الأنبوب يغذي أروع, أنظف, زيت عالي الضغط مباشرة إلى محمل مجلة CHRA. تصميم هذا الشاحن التربيني فاو تغذية النفط أمر بالغ الأهمية; يجب أن تكون خالية من مكامن الخلل, الشقوق, أو أي حطام.

يتم إغلاق اتصال الضغط العالي هذا باستخدام تركيبات البانجو المتخصصة. الترباس البانجو’ (q/xc3451.1 m16x1.5) هو مسمار مجوف يسمح بتدفق الزيت من خلاله. إنه مختوم بواسطة الحشيات’ (س/WC3403-94(16X22)). هذه عبارة عن غسالات سحق ناعمة من النحاس أو الألومنيوم. يتم وضع حشية واحدة على كل جانب من تركيبات البانجو. عندما يتم عزم الترباس, هذه الغسالات تشوه, خلق الكمال, ختم الضغط العالي. هذه الحشيات تستخدم لمرة واحدة. إعادة استخدامها سوف يسبب تسرب الزيت عالي الضغط, تجويع الشاحن التربيني فاو وخلق خطر نشوب حريق هائل بسبب رذاذ الزيت على غلاف التوربينات الساخنة. هذه نقطة خدمة مهمة لـ الشاحن التربيني فاو.

بعد أن يتم إجبار الزيت من خلال الشاحن التربيني فاو تحمل, ولم يعد تحت الضغط. يجب بعد ذلك تصريفه *خارجًا* من CHRA والعودة إلى وعاء الزيت. هذه هي مهمة مجموعة أنابيب إرجاع زيت الشاحن التوربيني’ (1118080-2000).

هذا قطر كبير, أنبوب الضغط المنخفض. تصميمه أمر بالغ الأهمية: يجب أن يكون واسعًا قدر الإمكان ويتم توجيهه بثبات, المنحدر الهبوطي (تغذية الجاذبية). أي شبك, تسد, أو نقطة منخفضة في خط العودة هذا ستتسبب في عودة الزيت إلى الداخل الشاحن التربيني فاومركز السكن.

عندما يحدث هذا النسخ الاحتياطي, ليس لضغط الزيت المتراكم مكان يذهب إليه سوى تجاوز مستوى ضغط الزيت الشاحن التربيني فاوالداخلية “حلقة المكبس” الأختام. وهذا هو السبب الرئيسي ل “الدخان الأزرق” من العادم, حيث يتم دفع الزيت إلى غلاف التوربينات الساخنة وحرقه. ويمكنه أيضًا دفع الزيت إلى داخل “الجانب البارد,” تلوث المبرد الداخلي. "المشبك". – أنبوب عودة زيت الشاحن التوربيني’ (1118083-81د) يستخدم لتأمين هذا الأنبوب.

أنبوب العودة هذا مغلق عند الشاحن التربيني فاو السكن بواسطة "طوقا". – أنبوب عودة زيت الشاحن التوربيني’ (1118094-29د), وفي كتلة المحرك بواسطة "الختم المطاطي ذو الحلقة الدائرية الهوائية الهيدروليكية".’ (Q07343236C). كلا الأختام ضرورية لمنع التسربات الخارجية. يعد مسار العودة بأكمله جزءًا أساسيًا من الشاحن التربيني فاو صحة النظام.

"الدرع الحراري للشاحن التوربيني."’ (1118031-1509) عبارة عن لوحة معدنية مختومة. وتتمثل مهمتها في الجلوس بين غلاف التوربينات الساخنة و “بارد” غلاف الضاغط, أو بين التوربين وكتلة المحرك. إنه يحجب الحرارة المشعة الشديدة من “الجانب الساخن” التابع الشاحن التربيني فاو.

يمنع هذا الدرع هذه الحرارة الشديدة من “فحم الكوك” (حرق) الزيت الموجود داخل مبيت المحمل المركزي بعد إيقاف تشغيل المحرك. هذا “نقع الحرارة” هو سبب رئيسي ل الشاحن التربيني فاو فشل. هذا الدرع, إلى جانب أدوات التثبيت المتنوعة الأخرى مثل "مسامير الحافة السداسية".’ (س1840830, س1840812, Q1840612, س1840816), يستخدم لتأمين الأنابيب المختلفة, المشابك, والدروع, ضمان كامل الشاحن التربيني فاو التجميع خالي من الاهتزاز ومحمي من الحرارة الخاصة به.

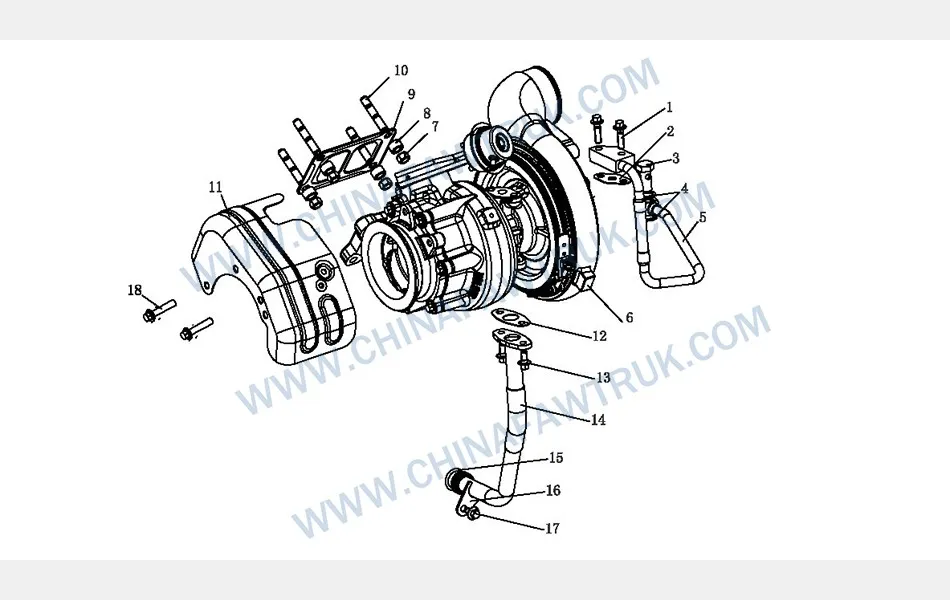

الجدول التالي يوفر كامل, تفصيل تفصيلي لجميع المكونات المحددة في "الشاحن التوربيني".’ رسم تخطيطي للجرار FAW CA4251P66K24T1A3E5. خدمة كاملة من الشاحن التربيني فاو يتطلب جميع الحشيات الجديدة, حلقات, والأزرار.

| علامة | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | س1840830 | الترباس شفة عرافة, قضيب خشن (نوع قياسي) | 2 |

| 2 | 1118063-D6 | طوقا – أنبوب مدخل الزيت | 1 |

| 3 | q/xc3451.1 m16x1.5 | الترباس البانجو | 1 |

| 4 | س/WC3403-94(16X22) | طوقا | 2 |

| 5 | 1118060-91دبليو | مجموعة أنابيب مدخل زيت الشاحن التوربيني (حسب العينة) | 1 |

| 6 | 1118010-91W-C00 | مجموعة الشاحن التوربيني | 1 |

| 7 | 1118073-29د | بندق – الشاحن التوربيني | 4 |

| 8 | 1118014-53د | كم – الشاحن التوربيني | 4 |

| 9 | 1118013A81D | حشية الشاحن التوربيني | 1 |

| 10 | 1118051-53د | الترباس ذو الرأسين للشاحن التوربيني | 4 |

| 11 | 1118031-1509 | درع حراري للشاحن التوربيني | 1 |

| 12 | 1118094-29د | طوقا – أنبوب عودة زيت الشاحن التوربيني | 1 |

| 13 | س1840812 | الترباس شفة عرافة, قضيب خشن (نوع قياسي) | 1 |

| 14 | 1118080-2000 | مجموعة أنابيب إرجاع زيت الشاحن التوربيني | 1 |

| 15 | Q07343236C | الهيدروليكية الهوائية O-حلقة مطاطية الختم | 1 |

| 16 | 1118083-81د | المشبك – أنبوب عودة زيت الشاحن التوربيني | 1 |

| 17 | Q1840612 | الترباس شفة عرافة, قضيب خشن (نوع قياسي) | 1 |

| 18 | س1840816 | الترباس شفة عرافة, قضيب خشن (نوع قياسي) | 2 |

المواصفات ل الشاحن التربيني فاو يتم تعريفها من خلال سرعتها العالية, عملية درجة حرارة عالية, تتطلب نظامًا قويًا للتركيب, تشحيم, والتدريع الحراري. كامل الشاحن التربيني فاو التجميع هو وحدة متوازنة الدقة.

| تطبيق المركبة | فاو جيفانغ CA4251P66K24T1A3E5 6×4 جرار |

| مجموعة المكونات | الشاحن التربيني فاو |

| الجمعية الرئيسية P/N | 1118010-91W-C00 |

| نظام تحمل | تحمل مجلة العائمة (زيت مشحم & تبريد) |

| نظام التركيب | 4-عشيق (1118051-53د) مع المكسرات (1118073-29د) & طوقا (1118013A81D) |

| نظام تغذية الزيت | أنبوب مدخل الضغط العالي (1118060-91دبليو) مع أختام البانجو (س/WC3403-94) |

| نظام إرجاع الزيت | أنابيب تغذية الجاذبية ذات الضغط المنخفض (1118080-2000) ث / طوقا (1118094-29د) |

| الإدارة الحرارية | 1× درع الحرارة للشاحن التوربيني (1118031-1509), 4× الأكمام (1118014-53د) | كم

| الوظيفة الأساسية | يستخدم طاقة غاز العادم لضغط الهواء الداخل (الحث القسري), زيادة قوة المحرك وكفاءته. |

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.