Bem-vindo a este guia técnico crítico sobre o Turbocompressor FAW (Parte não. 1118010-91W-C00), o componente adicionador de energia mais importante para o FAW Jiefang CA4251P66K24T1A3E5 6×4 trator semirreboque diesel. Este é o coração do sistema de indução forçada do motor.

O Turbocompressor FAW é responsável por forçar um grande volume de ar comprimido para dentro dos cilindros do motor, permitindo uma queima de combustível muito maior, que aumenta drasticamente a potência e o torque. Este componente é uma turbina projetada com precisão que gira a velocidades superiores a 150,000 RPM.

Este guia é um recurso essencial para técnicos profissionais, especialistas em motores, e gerentes de peças. Vamos desconstruir todo Turbocompressor FAW montagem e seus sistemas auxiliares críticos, incluindo a montagem de alta temperatura, a alimentação de óleo de alta pressão, e as linhas de retorno de óleo, até a menor unidade utilizável.

O componente principal é o 'Conjunto do Turbocompressor de Turbina’ (1118010-91W-C00). Este é o principal Turbocompressor FAW unidade. É um produto altamente equilibrado, montagem de precisão composta por duas metades principais: o “lado quente” e o “lado frio.”

**A turbina (Lado quente):** Os gases de escape quentes do motor são canalizados diretamente para a carcaça da turbina. Este gás de alta pressão gira uma roda de turbina, que é feito de um exótico, superliga de alta temperatura como Inconel, capaz de suportar mais de 900°C (1650° f). Este é o “motor” que alimenta todo Turbocompressor FAW.

**O Compressor (Lado Frio):** A roda da turbina é conectada através de um eixo de aço temperado a um “roda do compressor” do lado frio. Esta roda é normalmente fresada a partir de um tarugo sólido de alumínio. Enquanto gira, atrai fresco, ar filtrado e o comprime (criando “impulsionar”), forçando-o no intercooler e no coletor de admissão do motor.

**A CHRA (Conjunto giratório do cubo central):** O eixo que conecta essas duas rodas gira a velocidades incríveis em um “flutuante” sistema de rolamento de diário. Este rolamento, no coração do Turbocompressor FAW, não toca fisicamente o eixo; ele passa por uma película microscópica de óleo de motor de alta pressão, que lubrifica e esfria. A integridade desta película de óleo é o fator mais importante na Turbocompressor FAW longevidade.

Montando o Turbocompressor FAW é um desafio de calor extremo. Ele é parafusado diretamente no coletor de escapamento, qual é a parte mais quente do motor. Para lidar com isso, o sistema depende de hardware especializado. Os quatro parafusos prisioneiros de cabeça dupla do turbocompressor’ (1118051-53D) são rosqueados primeiro no coletor de escapamento. Estes são feitos de alta resistência, aço resistente ao calor.

A ‘junta do turbocompressor’ (1118013A81D) é colocado nesses pinos. Esta não é uma junta de papel; é um aço multicamadas (MLS) junta, projetado para ser esmagado entre o coletor e o Turbocompressor FAW carcaça da turbina. Deve conter a alta pressão, gases de escape superaquecidos, evitando vazamentos. Um vazamento na junta de entrada da turbina irá “assobiar” e causar uma perda severa de pressão de reforço.

O Turbocompressor FAW é então deslizado sobre as vigas, seguido pelos quatro 'Manga – turbocompressor’ (1118014-53D). Essas mangas são críticas; eles atuam como espaçadores de precisão e, mais importante, isoladores térmicos, ajudando a evitar que as porcas absorvam todo o calor da carcaça da turbina. Finalmente, os quatro ‘Noz – turbocompressor’ (1118073-29D) estão apertados. Estes são especiais “contraporcas,” muitas vezes feito de aço anti-torção, projetado para resistir ao afrouxamento sob ciclos extremos de calor e vibração. Todo este conjunto de hardware é essencial para uma operação confiável Turbocompressor FAW instalação.

A Turbocompressor FAW girando em 150,000 O RPM será destruído em menos de cinco segundos sem óleo. O ‘Conjunto do tubo de entrada de óleo do turbocompressor’ (1118060-91C) é a sua tábua de salvação. Este é um pré-formado, tubo de aço rígido projetado para entrar em uma galeria de óleo de alta pressão no bloco do motor.

Este tubo alimenta o mais legal, mais limpo, óleo de mais alta pressão diretamente para o mancal do CHRA. O design deste Turbocompressor FAW alimentação de óleo é crítica; deve estar livre de dobras, rachaduras, ou quaisquer detritos.

Esta conexão de alta pressão é vedada com acessórios especializados para banjo. O 'parafuso Banjo’ (Q/XC3451.1 M16X1.5) é um parafuso oco que permite que o óleo flua através dele. É selado pelas duas 'Juntas’ (Q/WC3403-94(16X22)). Estas são arruelas de cobre macio ou alumínio. Uma junta é colocada em cada lado da conexão do banjo. Quando o parafuso é apertado, essas arruelas se deformam, criando um perfeito, vedação de alta pressão. Estas juntas são descartáveis. Reutilizá-los causará um vazamento de óleo de alta pressão, morrendo de fome Turbocompressor FAW e criando um enorme risco de incêndio à medida que o óleo espirra na carcaça da turbina em brasa. Este é um ponto de serviço crítico para o Turbocompressor FAW.

Depois que o óleo é forçado através do Turbocompressor FAW consequência, não está mais sob pressão. Ele deve então drenar *para fora* do CHRA e voltar para o cárter. Este é o trabalho do ‘Montagem do tubo de retorno de óleo do turbocompressor’ (1118080-2000).

Este é um diâmetro grande, tubo de baixa pressão. Seu design é crítico: deve ser o mais largo possível e encaminhado com uma constante, inclinação descendente (alimentação por gravidade). Qualquer torção, entupir, ou ponto baixo nesta linha de retorno fará com que o óleo volte para dentro do Turbocompressor FAWhabitação central.

Quando esse backup ocorre, a pressão acumulada do óleo não tem para onde ir, a não ser além do Turbocompressor FAWé interno “anel de pistão” vedações. Esta é uma causa primária de “fumaça azul” do escapamento, à medida que o óleo é forçado para dentro da carcaça quente da turbina e queimado. Também pode forçar o óleo para dentro do “lado frio,” sujando o intercooler. A ‘braçadeira – tubo de retorno de óleo do turbocompressor’ (1118083-81D) é usado para proteger este tubo.

Este tubo de retorno é vedado no Turbocompressor FAW habitação pela ‘Gasket – tubo de retorno de óleo do turbocompressor’ (1118094-29D), e no bloco do motor pelo 'O-ring de vedação de borracha pneumático hidráulico’ (Q07343236C). Ambas as vedações são essenciais para evitar vazamentos externos. Todo esse caminho de retorno é uma parte fundamental do Turbocompressor FAW saúde do sistema.

O ‘escudo térmico do turbocompressor’ (1118031-1509) é uma placa de metal estampada. Sua função é ficar entre a carcaça da turbina em brasa e o “frio” carcaça do compressor, ou entre a turbina e o bloco do motor. Bloqueia o intenso calor radiante do “lado quente” do Turbocompressor FAW.

Este escudo evita que esse calor extremo “coque” (queimando) o óleo dentro da caixa do rolamento central depois que o motor é desligado. Esse “imersão em calor” é uma das principais causas Turbocompressor FAW falha. Este escudo, junto com outros fixadores diversos, como os 'parafusos de flange sextavados’ (Q1840830, Q1840812, Q1840612, Q1840816), é usado para proteger os vários tubos, braçadeiras, e escudos, garantindo toda Turbocompressor FAW a montagem está livre de vibrações e protegida do seu próprio calor.

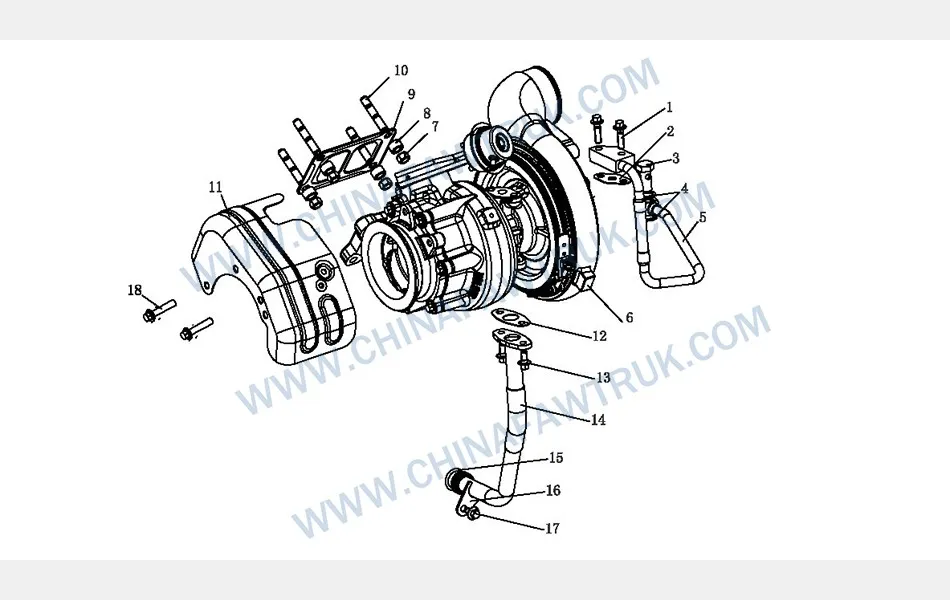

A tabela a seguir fornece o completo, detalhamento detalhado de todos os componentes identificados no 'Turbocompressor’ diagrama para o trator FAW CA4251P66K24T1A3E5. Um serviço completo de Turbocompressor FAW requer todas as novas juntas, anéis de vedação, e pregos.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | Q1840830 | Parafuso de flange sextavado, haste grossa (Tipo padrão) | 2 |

| 2 | 1118063-D6 | Junta – tubo de entrada de óleo | 1 |

| 3 | Q/XC3451.1 M16X1.5 | Parafuso de banjo | 1 |

| 4 | Q/WC3403-94(16X22) | Junta | 2 |

| 5 | 1118060-91C | Conjunto do tubo de entrada de óleo do turbocompressor (conforme amostra) | 1 |

| 6 | 1118010-91W-C00 | Conjunto de turbocompressor de turbina | 1 |

| 7 | 1118073-29D | Noz – turbocompressor | 4 |

| 8 | 1118014-53D | Manga – turbocompressor | 4 |

| 9 | 1118013A81D | Junta do turbocompressor | 1 |

| 10 | 1118051-53D | Parafuso prisioneiro de cabeça dupla do turbocompressor | 4 |

| 11 | 1118031-1509 | Escudo térmico do turbocompressor | 1 |

| 12 | 1118094-29D | Junta – tubo de retorno de óleo do turbocompressor | 1 |

| 13 | Q1840812 | Parafuso de flange sextavado, haste grossa (Tipo padrão) | 1 |

| 14 | 1118080-2000 | Conjunto do tubo de retorno de óleo do turbocompressor | 1 |

| 15 | Q07343236C | Vedação de borracha O-ring pneumática hidráulica | 1 |

| 16 | 1118083-81D | Braçadeira – tubo de retorno de óleo do turbocompressor | 1 |

| 17 | Q1840612 | Parafuso de flange sextavado, haste grossa (Tipo padrão) | 1 |

| 18 | Q1840816 | Parafuso de flange sextavado, haste grossa (Tipo padrão) | 2 |

As especificações para o Turbocompressor FAW são definidos pela sua alta velocidade, operação em alta temperatura, exigindo um sistema robusto para montagem, lubrificação, e blindagem térmica. O inteiro Turbocompressor FAW montagem é uma unidade balanceada com precisão.

| Aplicação em veículos | FAW Jiefang CA4251P66K24T1A3E5 6×4 Trator |

| Grupo de Componentes | Turbocompressor FAW |

| Conjunto principal P/N | 1118010-91W-C00 |

| Sistema de rolamento | Rolamento de diário flutuante (Lubrificado com óleo & Resfriado) |

| Sistema de montagem | 4-Viga (1118051-53D) com nozes (1118073-29D) & Junta (1118013A81D) |

| Sistema de alimentação de óleo | Tubo de entrada de alta pressão (1118060-91C) com focas de banjo (Q/WC3403-94) |

| Sistema de retorno de óleo | Tubo de alimentação por gravidade de baixa pressão (1118080-2000) com junta (1118094-29D) |

| Gestão Térmica | 1x Escudo térmico do turbocompressor (1118031-1509), 4x Mangas (1118014-53D) | Manga

| Função Primária | Usa a energia dos gases de escape para comprimir o ar de admissão (indução forçada), aumentando a potência e a eficiência do motor. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.