Добро пожаловать к этому эксперту, подробное руководство по Система подачи топлива FAW, полный “Common Rail высокого давления” (HPCR) система для FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. Это самая сложная и точная система во всей трансмиссии..

The Система подачи топлива FAW отвечает за забор топлива из бака, фильтруя его до микроскопического уровня, давить на него слишком сильно 30,000 пси, а затем впрыскивает его с точностью до миллисекунды непосредственно в цилиндры двигателя.. Производительность этой системы определяет мощность двигателя., экономия топлива, и выбросы.

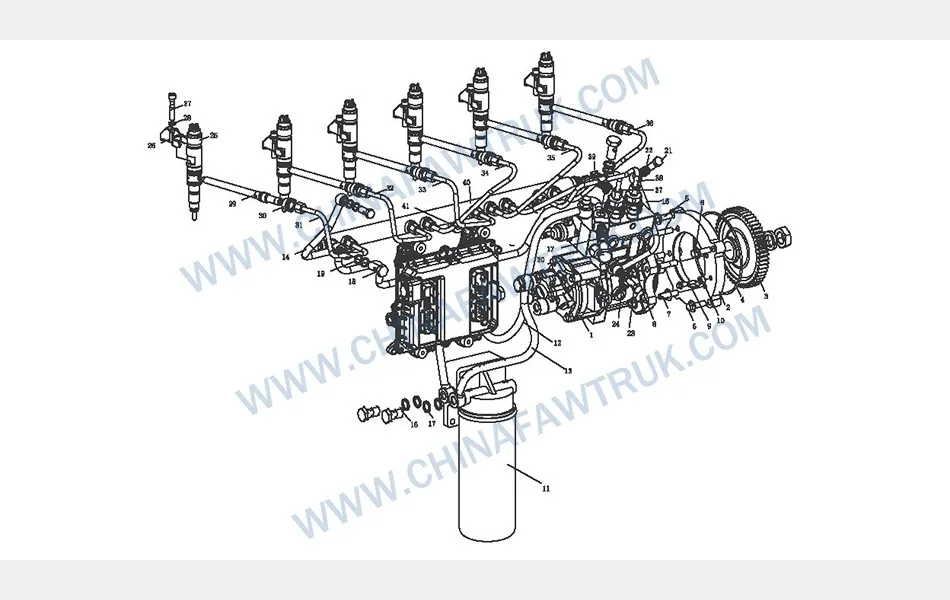

Это руководство является важным ресурсом для профессиональных специалистов по дизельным двигателям., менеджеры автопарка, и специалисты по запчастям. Мы разберем всю Система подачи топлива FAW, от контура подъема низкого давления и фильтра тонкой очистки к насосу высокого давления, общая железнодорожная магистраль, и шесть отдельных линий инжектора, разобрав его до каждой исправной гайки, болт, и запечатать.

Сердце Система подачи топлива FAW это «Топливный насос высокого давления в сборе»’ (1111010-73Д). Это невероятно точно, высокомоментный насос, создающий низкое давление, фильтруют дизельное топливо и сжимают его до 30,000+ пси (2000+ бар) требуется для Common Rail. Это “Common Rail” насос, это означает, что его работа заключается только в создании давления; это не синхронизировано с форсунками.

Этот насос представляет собой компонент с зубчатым приводом., интегрирован непосредственно в систему газораспределения двигателя. «Приводная шестерня ТНВД’ (1111216-81Д) входит в зацепление с зубчатой передачей газораспределительного механизма двигателя, обеспечение того, чтобы насос всегда вращался при работающем двигателе.. Он жестко крепится к блоку двигателя через соединительный фланец топливного насоса высокого давления.’ (1111228-81Д). Это крепление точно расположено с помощью «установочного штифта».’ (1111226-59Д) и «Рукав’ (1111227-59Д), затем закрепил шпильками’ (CQ1201030) и «Шестигранные фланцевые гайки’ (CQ39610).

Этот насос также смазывается моторным маслом.. Масловпускной патрубок ТНВД «Банджо»’ (1104076-73Д) и «Впускная труба моторного масла в сборе».’ (1104070-81Д) подавать чистое масло во внутренние подшипники. Это делает Система подачи топлива FAWглавный насос комплекса, критически важный компонент, для выживания которого требуется как чистое топливо, так и чистое масло.

Если насос — это сердце, «Рельс высокого давления в сборе»’ (1129110-81Д) это мозг. Это “Common Rail” сам. Это толстостенный, кованая стальная трубка, выполняющая роль аккумулятора давления.. Его задача — накапливать топливо под высоким давлением из насоса и равномерно распределять его по всем шести цилиндрам..

Эта рейка питается от насоса по двум отдельным трубам.: «Узел маслопровода высокого давления I’ (1129070-81Д) и «Узел маслопровода высокого давления II».’ (1129080-81Д). Такая конструкция с двойной подачей гарантирует, что давление в рельсе остается стабильным., даже при большой нагрузке.

Рейка крепится к головке двигателя с помощью фланцевых болтов с шестигранной головкой.’ (Q1840835). Это центральный распределительный узел для всей стороны высокого давления. Система подачи топлива FAW. Обычно он также содержит главный датчик давления топлива и предохранительный клапан., которые являются основными входами для ЭБУ двигателя..

Этот модуль содержит “доставка” компоненты Система подачи топлива FAW. В системе используется шесть «Инжекторных сборок».’ (1112010-51Б) единицы. Это не простые насадки; они очень продвинуты, с электронным управлением (соленоид или пьезоэлектрический) форсунки. Они получают “огонь” сигнал от ЭБУ, открытие всего на миллисекунды, чтобы взорвать штраф, распыленный туман топлива в камеру сгорания.

Каждая форсунка питается от общей топливной магистрали своим индивидуальным, предварительно изогнутая стальная труба. Это «Маслопровод высокого давления первого цилиндра в сборе».’ (1129010-81Д) через узел маслопровода высокого давления шестого цилиндра’ (1129060-81Д). Эти шесть трубок одноразовые. “раздавить” линии и должны быть заменены, если они ослаблены, чтобы обеспечить герметичное уплотнение.. Они являются артериями Система подачи топлива FAW.

Сами форсунки установлены глубоко внутри головки блока цилиндров.. Соединитель маслопровода высокого давления в сборе.’ (1112030-81Д) с промежуточной компрессионной гайкой’ (1112031-29Д) образует уплотнение высокого давления на входе в форсунку. Каждая форсунка удерживается с чрезвычайной силой «зажимом форсунки».’ (1112011-81Д), «Болт крепления форсунки’ (1112013-81Д), и «Сферическая шайба’ (1112014-81Д). Эта система зажимов и болтов имеет решающее значение для предотвращения выдувания форсунки из головки под давлением сгорания.. Весь этот узел является “конец бизнеса” принадлежащий Система подачи топлива FAW.

Насос высокого давления может работать только при постоянной подаче чистой воды., топливо низкого давления. Это работа стороны низкого давления. Система подачи топлива FAW. А (вероятный) механический подъемный насос, интегрирован в основной насосный агрегат ВД, забирает топливо из бака.

Это топливо проходит через перекачивающий насос впускного трубопровода к фильтру тонкой очистки.’ (1104030А51Б). Эта линия защищена впускным/выпускным отверстием перекачивающего насоса с помощью болта-банджо.’ (1104036-73Д) и уплотнены уплотнительными кольцами’ (CQ72316T5).

Эта трубка питает блок фильтра тонкой очистки топлива.’ (1117010-81Д), который (как подробно описано в нашем предыдущем руководстве) является важнейшим компонентом для удаления воды и микроскопического мусора.. Это “почка” принадлежащий Система подачи топлива FAW.

После очистки топлива, он течет через «Впускной патрубок в сборе — фильтр тонкой очистки» к насосу высокого давления.’ (1104040А51Б), который запечатан болтами банджо’ (1117038-60Д) и прокладки. Эта труба обеспечивает чистую, топливо низкого давления, которое сжимает насос ВД. Весь Система подачи топлива FAW зависит от герметичности и отсутствия утечек этого контура низкого давления..

The Система подачи топлива FAW есть еще два жизненно важных “сантехника” схемы. Первый, «Обратный трубопровод в сборе»’ (1104050-81Д) это линия возврата топлива. Форсунки HPCR и клапан сброса давления на рейке “утечка” или “обойти” определенное количество топлива для работы. Этот “возвращаться” топливо собирается и отправляется обратно в бак через эту трубку., завершение топливного контура.

Второй, как уже упоминалось, насос высокого давления смазывается моторным маслом, не дизельное топливо. «Впускная трубка моторного масла в сборе»’ (1104070-81Д) предоставляет это масло. Это линия высокого давления, герметизированная узлом смазочной трубки двигателя с болтом-банджо.’ (1104076-53Д) и «Уплотнительные кольца’ (CQ72312T5). После смазки насоса, масло выходит через возвратную масляную трубку двигателя с болтом типа «банджо».’ (1104073-D6). Вся эта подсистема смазки имеет решающее значение для срока службы Система подачи топлива FAWглавный насос.

В следующей таблице представлена полная, подробная разбивка всех компонентов, указанных в «Системе подачи топлива».’ схема трактора FAW CA4251P66K24T1A3E5. Этот Система подачи топлива FAW представляет собой высокоточный, сборка с нулевым допуском.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1111010-73Д | Топливный насос высокого давления в сборе | 1 |

| 2 | 1111228-81Д | Соединительный фланец топливного насоса высокого давления | 1 |

| 3 | 1111216-81Д | Шестерня привода ТНВД | 1 |

| 4 | Q073431550C | Гидравлическое пневматическое резиновое уплотнительное кольцо | 1 |

| 5 | Q1841030 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 2 |

| 6 | Q1841040 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 2 |

| 7 | CQ1201030 | Шпилька болт | 4 |

| 8 | CQ39610 | Шестигранная фланцевая гайка | 4 |

| 9 | 1111226-59Д | Дюбель-штифт | 1 |

| 10 | 1111227-59Д | Рукав | 1 |

| 11 | 1117010-81Д | Топливный фильтр тонкой очистки в сборе (по образцу) | 1 |

| 12 | 1104030А51Б | Впускной патрубок в сборе — перекачивающий насос к фильтру тонкой очистки (по образцу) | 1 |

| 13 | 1104040А51Б | Впускной патрубок в сборе — фильтр тонкой очистки к насосу высокого давления (по образцу) | 1 |

| 14 | 1104050-81Д | Сборка обратной трубы (по образцу) | 1 |

| 15 | 1104070-81Д | Впускная трубка моторного масла в сборе (по образцу) | 1 |

| 16 | 1104036-73Д | Болт-банджо, вход/выход перекачивающего насоса | 6 |

| 17 | CQ72316T5 | Уплотнительное кольцо | 14 |

| 18 | 1104073-D6 | Банджо-болт-обратная маслопроводная трубка двигателя | 2 |

| 19 | CQ72314T5 | Уплотнительное кольцо | 4 |

| 20 | 1117038-60Д | Банджо-болт | 1 |

| 21 | 1104076-53Д | Банджо-болт-смазочная трубка двигателя в сборе | 1 |

| 22 | CQ72312T5 | Уплотнительное кольцо | 2 |

| 23 | 1104076-73Д | Банджо-болт-впуск масла ТНВД | 1 |

| 24 | CQ72310T5 | Уплотнительное кольцо | 2 |

| 25 | 1112010-51Б | Сборка инжектора | 6 |

| 26 | 1112011-81Д | Зажим форсунки | 6 |

| 27 | 1112013-81Д | Болт крепления форсунки | 6 |

| 28 | 1112014-81Д | Сферическая шайба | 6 |

| 29 | 1112030-81Д | Соединитель маслопровода высокого давления в сборе | 6 |

| 30 | 1112031-29Д | Промежуточная компрессионная гайка-соединитель трубопровода высокого давления | 1 |

| 31 | 1129010-81Д | Маслопровод высокого давления первого цилиндра в сборе | 1 |

| 32 | 1129020-81Д | Маслопровод высокого давления второго цилиндра в сборе | 1 |

| 33 | 1129030-81Д | Маслопровод высокого давления третьего цилиндра в сборе | 1 |

| 34 | 1129040-81Д | Маслопровод высокого давления четвертого цилиндра в сборе | 1 |

| 35 | 1129050-81Д | Маслопровод высокого давления пятого цилиндра в сборе | 1 |

| 36 | 1129060-81Д | Маслопровод высокого давления шестого цилиндра в сборе | 1 |

| 37 | 1129070-81Д | Маслопровод высокого давления в сборе I – Насос ВД к рейке ВД | 1 |

| 38 | 1129080-81Д | Узел маслопровода высокого давления II – Насос ВД к рейке ВД | 1 |

| 39 | 1129090-73Д | Хомут маслопровода высокого давления в сборе I | 1 |

| 40 | 1129110-81Д | Сборка рампы высокого давления | 1 |

| 41 | Q1840835 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 3 |

Технические характеристики Система подачи топлива FAW определяются своей функцией как устройство высокого давления, система впрыска дизельного топлива с электронным управлением. Весь Система подачи топлива FAW представляет собой высокоточный, сборка с нулевым допуском.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | Система подачи топлива FAW |

| Тип системы | Common Rail высокого давления (HPCR) |

| Насос высокого давления | 1х (Часть №. 1111010-73Д), с зубчатым приводом |

| Рельс высокого давления | 1х (Часть №. 1129110-81Д), Двойная подача |

| Форсунки | 6x Электронные форсунки в сборе (1112010-51Б) |

| Инжекторные линии | 6x Отдельные стальные трубы (1129010-81Д к 1129060-81Д) |

| Смазка насоса | Моторное масло под давлением (1104070-81Д) |

| Фильтрация (Сборка) | 1x Узел фильтра тонкой очистки топлива (1117010-81Д) |

| Основная функция | Фильтровать, оказывать давление (к 30,000+ пси), и впрыскивайте дизельное топливо с точным расчетом времени.. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..