Welcome to this expert, in-depth guide to the Système d'alimentation en carburant FAW, le complet “high-pressure common rail” (Hpcr) système pour le FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This is the single most complex and precise system in the entire powertrain.

Le Système d'alimentation en carburant FAW is responsible for drawing fuel from the tank, filtering it to a microscopic level, pressurizing it to over 30,000 psi, and then injecting it with millisecond-precision directly into the engine’s cylinders. This system’s performance dictates engine power, économie de carburant, and emissions.

This guide is an essential resource for professional diesel technicians, gestionnaires de flotte, et spécialistes des pièces détachées. Nous déconstruirons l'ensemble Système d'alimentation en carburant FAW, from the low-pressure lift circuit and fine filter to the high-pressure pump, the common rail, and the six individual injector lines, breaking it down to every last serviceable nut, boulon, and seal.

Le coeur du Système d'alimentation en carburant FAW is the ‘High pressure fuel pump assembly’ (1111010-73D). This is an incredibly precise, high-torque pump that draws in low-pressure, filtered diesel and compresses it to the 30,000+ psi (2000+ bar) required by the common rail. C'est un “common rail” pompe, meaning its job is only to generate pressure; it is not timed to the injectors.

This pump is a gear-driven component, integrated directly into the engine’s timing. The ‘Injection pump drive gear’ (1111216-81D) meshes with the engine’s timing gear train, ensuring the pump is always turning when the engine is. It is rigidly mounted to the engine block via the ‘High pressure fuel pump connecting flange’ (1111228-81D). This mounting is precisely located by a ‘Dowel pin’ (1111226-59D) and ‘Sleeve’ (1111227-59D), then secured with ‘Stud bolts’ (CQ1201030) et « Écrous à bride hexagonale’ (CQ39610).

This pump is also lubricated by engine oil. The ‘Banjo bolt-injection pump oil inlet’ (1104076-73D) and ‘Engine oil inlet pipe assembly’ (1104070-81D) supply clean oil to its internal bearings. Cela rend le Système d'alimentation en carburant FAW‘s main pump a complex, mission-critical component that relies on both clean fuel and clean oil to survive.

If the pump is the heart, the ‘High pressure rail assembly’ (1129110-81D) is the brain. C'est le “common rail” lui-même. It is a thick-walled, forged steel tube that acts as a pressure accumulator. Its job is to store the high-pressure fuel from the pump and distribute it evenly to all six cylinders.

This rail is fed by two separate pipes from the pump: ‘High pressure oil pipe assembly I’ (1129070-81D) and ‘High pressure oil pipe assembly II’ (1129080-81D). This dual-feed design ensures the rail’s pressure remains stable, even under high load.

The rail is mounted to the engine head with ‘Hex flange bolts’ (Q1840835). It is the central distribution hub for the entire high-pressure side of the Système d'alimentation en carburant FAW. It also typically houses the master fuel pressure sensor and a pressure relief valve, which are the primary inputs for the engine’s ECU.

This module contains the “livraison” composants du Système d'alimentation en carburant FAW. The system uses six ‘Injector assembly’ (1112010-51B) unités. These are not simple nozzles; they are highly advanced, electronically controlled (solenoid or piezo) injecteurs. They receive the “feu” signal from the ECU, opening for just milliseconds to blast a fine, atomized mist of fuel into the combustion chamber.

Each injector is fed from the common rail by its own individual, pre-bent steel pipe. These are the ‘First cylinder high pressure oil pipe assembly’ (1129010-81D) through the ‘Sixth cylinder high pressure oil pipe assembly’ (1129060-81D). These six pipes are single-use “crush-fit” lines and must be replaced if ever loosened to ensure a leak-free seal. They are the arteries of the Système d'alimentation en carburant FAW.

The injectors themselves are mounted deep inside the cylinder head. A ‘High pressure oil pipe connector assembly’ (1112030-81D) with an ‘Intermediate compression nut’ (1112031-29D) forms the high-pressure seal at the injector’s inlet. Each injector is held down with extreme force by an ‘Injector clamp’ (1112011-81D), an ‘Injector clamp bolt’ (1112013-81D), and a ‘Spherical washer’ (1112014-81D). This clamp-and-bolt system is critical to prevent the injector from being blown out of the head by combustion pressure. This entire sub-assembly is the “fin des affaires” de la Système d'alimentation en carburant FAW.

The high-pressure pump can only work if it is fed a constant supply of clean, low-pressure fuel. This is the job of the low-pressure side of the Système d'alimentation en carburant FAW. UN (probable) mechanical lift pump, integrated into the main HP pump assembly, pulls fuel from the tank.

This fuel travels through the ‘Inlet pipe assembly-transfer pump to fine filter’ (1104030A51B). This line is secured by ‘Banjo bolt-transfer pump inlet/outlet’ (1104036-73D) and sealed by ‘Gasket rings’ (CQ72316T5).

This pipe feeds the ‘Fuel fine filter assembly’ (1117010-81D), lequel (as detailed in our previous guide) is the critical component for removing water and microscopic debris. C'est le “rein” de la Système d'alimentation en carburant FAW.

After the fuel is cleaned, it flows through the ‘Inlet pipe assembly-fine filter to high pressure pump’ (1104040A51B), which is sealed with ‘Banjo bolts’ (1117038-60D) and gaskets. This pipe delivers the clean, low-pressure fuel that the HP pump will compress. L'ensemble Système d'alimentation en carburant FAW depends on this low-pressure loop being airtight and leak-free.

Le Système d'alimentation en carburant FAW has two other vital “plomberie” circuits. D'abord, the ‘Return pipe assembly’ (1104050-81D) is the fuel return line. HPCR injectors and the pressure relief valve on the rail “fuir” ou “by-pass” a certain amount of fuel to function. Ce “retour” fuel is collected and sent back to the tank via this pipe, completing the fuel circuit.

Deuxième, as mentioned, the high-pressure pump is lubricated by engine oil, not diesel fuel. The ‘Engine oil inlet pipe assembly’ (1104070-81D) provides this oil. It is a high-pressure line sealed with ‘Banjo bolt-engine oil lube pipe assembly’ (1104076-53D) and ‘Gasket rings’ (CQ72312T5). After lubricating the pump, the oil exits via a ‘Banjo bolt-engine oil return pipe’ (1104073-D6). This entire oiling sub-system is crucial to the life of the Système d'alimentation en carburant FAW‘s main pump.

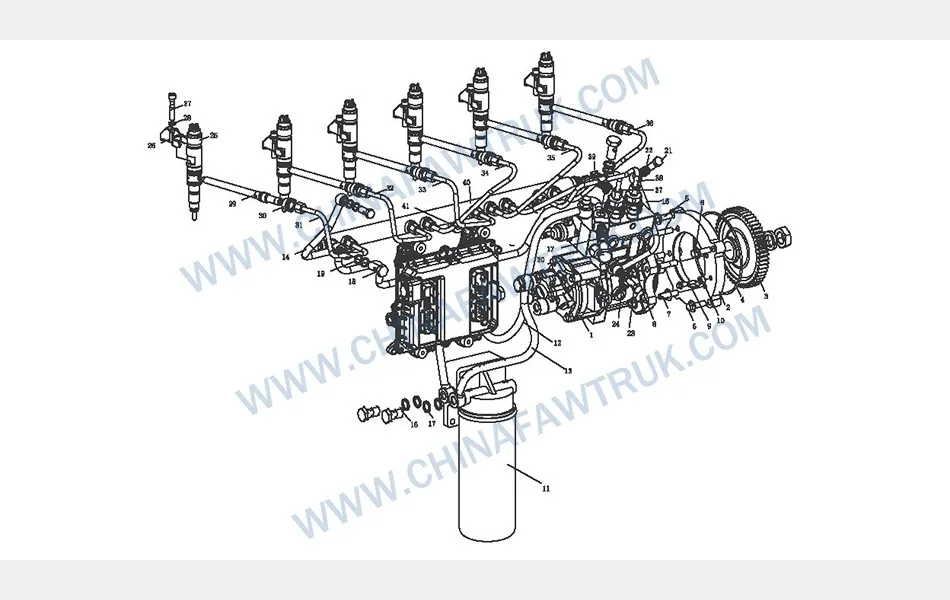

Le tableau suivant fournit l'intégralité, detailed breakdown of all components identified in the ‘Fuel Supply System’ schéma du tracteur FAW CA4251P66K24T1A3E5. Ce Système d'alimentation en carburant FAW est un appareil de haute précision, zero-tolerance assembly.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1111010-73D | Ensemble pompe à carburant haute pression | 1 |

| 2 | 1111228-81D | High pressure fuel pump connecting flange | 1 |

| 3 | 1111216-81D | Injection pump drive gear | 1 |

| 4 | Q073431550C | Joint torique pneumatique hydraulique en caoutchouc | 1 |

| 5 | Q1841030 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

| 6 | Q1841040 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

| 7 | CQ1201030 | Boulon de goujon | 4 |

| 8 | CQ39610 | Écrou à bride hexagonale | 4 |

| 9 | 1111226-59D | Goupille | 1 |

| 10 | 1111227-59D | Manche | 1 |

| 11 | 1117010-81D | Assemblage du filtre fin à carburant (selon l'échantillon) | 1 |

| 12 | 1104030A51B | Inlet pipe assembly-transfer pump to fine filter (selon l'échantillon) | 1 |

| 13 | 1104040A51B | Inlet pipe assembly-fine filter to high pressure pump (selon l'échantillon) | 1 |

| 14 | 1104050-81D | Assemblage de tuyaux de retour (selon l'échantillon) | 1 |

| 15 | 1104070-81D | Engine oil inlet pipe assembly (selon l'échantillon) | 1 |

| 16 | 1104036-73D | Banjo bolt-transfer pump inlet/outlet | 6 |

| 17 | CQ72316T5 | Bague d'étanchéité | 14 |

| 18 | 1104073-D6 | Banjo bolt-engine oil return pipe | 2 |

| 19 | CQ72314T5 | Bague d'étanchéité | 4 |

| 20 | 1117038-60D | Banjo bolt | 1 |

| 21 | 1104076-53D | Banjo bolt-engine oil lube pipe assembly | 1 |

| 22 | CQ72312T5 | Bague d'étanchéité | 2 |

| 23 | 1104076-73D | Banjo bolt-injection pump oil inlet | 1 |

| 24 | CQ72310T5 | Bague d'étanchéité | 2 |

| 25 | 1112010-51B | Assemblage d'injecteur | 6 |

| 26 | 1112011-81D | Injector clamp | 6 |

| 27 | 1112013-81D | Injector clamp bolt | 6 |

| 28 | 1112014-81D | Rondelle sphérique | 6 |

| 29 | 1112030-81D | High pressure oil pipe connector assembly | 6 |

| 30 | 1112031-29D | Intermediate compression nut-high pressure pipe connector | 1 |

| 31 | 1129010-81D | First cylinder high pressure oil pipe assembly | 1 |

| 32 | 1129020-81D | Second cylinder high pressure oil pipe assembly | 1 |

| 33 | 1129030-81D | Third cylinder high pressure oil pipe assembly | 1 |

| 34 | 1129040-81D | Fourth cylinder high pressure oil pipe assembly | 1 |

| 35 | 1129050-81D | Fifth cylinder high pressure oil pipe assembly | 1 |

| 36 | 1129060-81D | Sixth cylinder high pressure oil pipe assembly | 1 |

| 37 | 1129070-81D | High pressure oil pipe assembly I – HP pump to HP rail | 1 |

| 38 | 1129080-81D | High pressure oil pipe assembly II – HP pump to HP rail | 1 |

| 39 | 1129090-73D | High pressure oil pipe clamp assembly I | 1 |

| 40 | 1129110-81D | High pressure rail assembly | 1 |

| 41 | Q1840835 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 3 |

Les spécifications pour le Système d'alimentation en carburant FAW sont définis par sa fonction de système haute pression, electronically controlled diesel injection system. L'ensemble Système d'alimentation en carburant FAW est un appareil de haute précision, zero-tolerance assembly.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Système d'alimentation en carburant FAW |

| Type de système | Rail commun haute pression (Hpcr) |

| High Pressure Pump | 1x (Partie no. 1111010-73D), Entraîné par engrenage |

| High Pressure Rail | 1x (Partie no. 1129110-81D), Dual-Feed |

| Injecteurs | 6x Electronic Injector Assemblies (1112010-51B) |

| Injector Lines | 6x Individual Steel Pipes (1129010-81D to 1129060-81D) |

| Pump Lubrication | Pressurized Engine Oil (1104070-81D) |

| Filtration (Sub-Assembly) | 1x Fuel Fine Filter Assembly (1117010-81D) |

| Fonction principale | To filter, pressurize (à 30,000+ psi), and inject diesel fuel with precision timing. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.