Bienvenue dans ce guide critique sur le Filtre fin à carburant FAW (Partie no. 1117010-81D), la ligne de défense la plus importante pour le système d'injection de carburant haute pression du FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel.

Ce composant n'est pas qu'un simple écran; le moderne Filtre fin à carburant FAW est une unité avancée de coalescence et de filtration à plusieurs étages. Son seul objectif est d'éliminer les particules abrasives microscopiques et, le plus important, toutes les traces d'eau du carburant diesel avant qu'il n'atteigne la pompe à rampe commune et les injecteurs de plusieurs milliers de PSI.

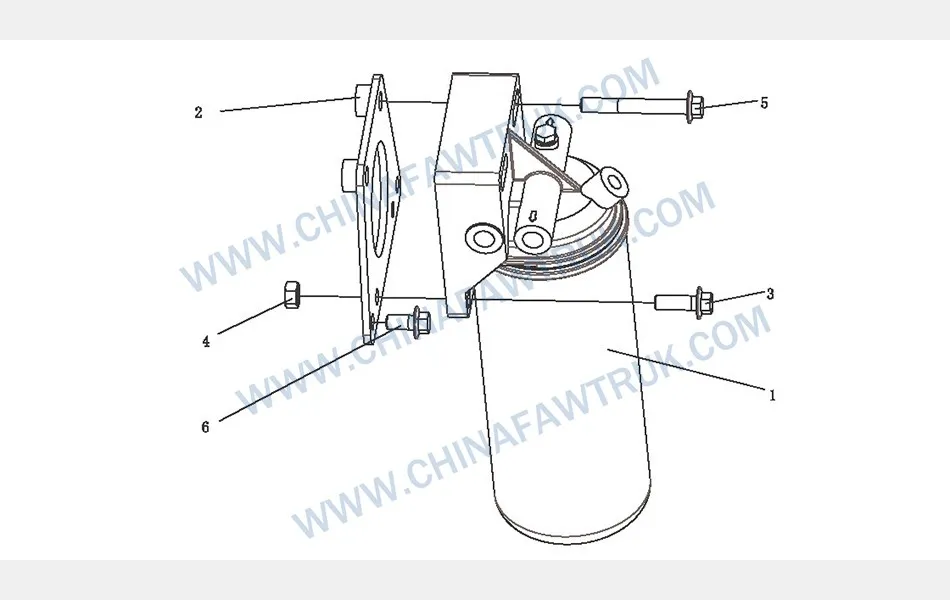

Ce guide est une ressource essentielle pour les techniciens professionnels, responsables de l'entretien de la flotte, et spécialistes des pièces détachées. Nous déconstruirons l'ensemble Filtre fin à carburant FAW assemblée, y compris sa base de montage permanente, sa cartouche remplaçable, et son support rigide, jusqu'au dernier écrou et boulon réparable.

La liste des pièces pour Mark 1 détaille les trois éléments clés du Filtre fin à carburant FAW système. La pièce parente est l'ensemble de filtre fin à carburant’ (1117010-81D), qui est l'unité complète. Cet ensemble est composé de deux pièces réparables distinctes:

**1. L'ensemble de base du filtre fin à carburant’ (1117020-81D):** C'est le permanent, non remplaçable “tête” du système. Il s'agit d'un boîtier en aluminium moulé avec précision qui se boulonne au support principal. Cette base contient les ports d'entrée et de sortie de carburant, le support fileté pour l'élément filtrant, et probablement les ports pour un préchauffeur de carburant et un “Eau dans le carburant” (WiF) capteur. Cette base est le centre de contrôle de l'ensemble Filtre fin à carburant FAW.

**2. L'ensemble d'éléments de filtre fin à carburant’ (1117050-81D):** C'est le “pièce de rechange” ou la cartouche. C'est le remplaçable, cartouche à visser qui contient le média filtrant réel. Lors d'une prestation, cet élément est la seule partie du Filtre fin à carburant FAW (1117010-81D) qui est jeté et remplacé. Sa conception est cruciale pour protéger le moteur.

Comprendre cette relation est essentiel: la base (7020) et l'élément (7050) combiner pour créer l'ensemble complet de filtre fin à carburant’ (7010). Un technicien entretient l'élément, mais la base reste fixée au camion. Cette modularité est un élément essentiel du Filtre fin à carburant FAW conception.

Le nom “Filtre fin à carburant” n'est pas un terme marketing; il s'agit d'une spécification technique critique. Ce Filtre fin à carburant FAW est la finale, et le plus important, étape de filtration avant que le carburant n'entre dans la rampe commune haute pression (Hpcr) système d'injection. Les composants de ce système, surtout les injecteurs, sont construits avec des tolérances inférieures à 3-5 microns (un cheveu humain, c'est environ 70 microns).

**1. Élimination des particules abrasives:** La tâche principale du Filtre fin à carburant FAW le média consiste à piéger les particules dures microscopiques. Cela inclut la silice (saleté fine) qui peut dépasser le filtre principal, et de la rouille ou des flocons de métal provenant des réservoirs de carburant et des stations. Si même une de ces particules atteint l’injecteur, ça fait office de sableuse, éroder le délicat pivot de l'injecteur et le siège de la buse. Cette érosion provoque une fuite de l'injecteur, ce qui entraîne une mauvaise atomisation du carburant, fumée noire, consommation de carburant élevée, et éventuelle panne moteur.

**2. Coalescence de l'eau (Séparation):** Le secondaire, et tout aussi critique, fonction du Filtre fin à carburant FAW est la séparation de l'eau. Le carburant diesel absorbe et transporte naturellement l’eau. Cette eau est catastrophique pour un système HPCR. D'abord, il provoque de la rouille et de la corrosion sur les surfaces internes usinées avec précision de la pompe et des injecteurs. Deuxième, quand l'eau (qui est incompressible) est soumis à 30,000+ psi, il peut instantanément souffler la pointe d'un injecteur. Les médias avancés dans le Filtre fin à carburant FAW est “hydrophobe.” Il repousse l'eau, forçant les minuscules gouttelettes d'eau émulsionnées à “se fondre” (fusionner) en plus grand, gouttelettes plus lourdes, qui tombent ensuite hors du flux de carburant et sont collectés dans un bol au bas de l'ensemble de filtre, où ils peuvent être vidés.

L'utilisation d'un élément filtrant non authentique peut détruire ce moteur. Un filtre bon marché qui ne peut pas répondre aux “bien” L'indice de micron ou l'impossibilité de fusionner correctement l'eau permettront à ces contaminants de passer, entraînant des milliers de dollars en réparations sur le système d'injection de carburant. L'ensemble Filtre fin à carburant FAW assemblée (1117010-81D) est le gardien qui protège les composants les plus coûteux du moteur. Cela rend le Filtre fin à carburant FAW l'une des pièces réparables les plus importantes sur l'ensemble du camion.

L'ensemble de support de filtre fin à carburant’ (1117120-81D) est la base structurelle de l’ensemble du système. C'est un véhicule robuste, support en acier estampé conçu pour être boulonné directement sur le longeron du châssis principal du camion.

Sa fonction est double. D'abord, il fournit une stabilité, emplacement de montage rigide pour l'ensemble de base du filtre fin à carburant’ (1117020-81D). Ceci est crucial pour prévenir les lourdes, ensemble de filtre rempli de carburant contre les vibrations. Deuxième, il isole le Filtre fin à carburant FAW système contre les vibrations à haute fréquence du moteur. En montant le filtre sur le “à ressort” châssis au lieu du “non suspendu” moteur, les conduites et raccords de carburant sont soumis à beaucoup moins de contraintes, prévenir la fatigue, fissure, et fuites dangereuses de carburant à haute pression.

La liste des pièces détaille un ensemble spécifique de fixations à haute résistance pour fixer le Filtre fin à carburant FAW système. Ce matériel n'est pas facultatif; il est conçu pour cette application spécifique.

**Fixations du support au châssis:** Les « boulons à bride hexagonale’ (Q1841075 et Q1841020), avec deux de chaque, sont les boulons principaux qui fixent l'assemblage du support’ (1117120-81D) au rail de châssis du camion. Les différents numéros de pièces indiquent des longueurs différentes, requis pour la géométrie spécifique du support de châssis. La tête de bride est essentielle pour répartir la charge et résister au desserrage dû aux vibrations de la route..

**Fixations base-support:** Les deux boulons à bride hexagonale’ (Q1841030) et deux écrous hexagonaux’ (CQ34010) sont le matériel utilisé pour fixer l'ensemble de base du filtre fin à carburant’ (1117020-81D) *à* l’« Assemblage du support ». Cette combinaison boulon-écrou permet à la base d'être solidement “pris en sandwich” sur le support, créer la finale, rigide Filtre fin à carburant FAW assemblée.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous les composants identifiés dans le « Filtre fin à carburant’ schéma du tracteur FAW CA4251P66K24T1A3E5. Entretien du Filtre fin à carburant FAW (1117050-81D) est une tâche de maintenance critique.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1117010-81D | Ensemble de filtre fin à carburant (selon l'échantillon) | 1 |

| 1117020-81D | Ensemble de base de filtre fin à carburant | 1 | |

| 1117050-81D | Ensemble d'élément de filtre fin à carburant (selon l'échantillon) | 1 | |

| 2 | 1117120-81D | Ensemble de support de filtre fin à carburant | 1 |

| 3 | Q1841030 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

| 4 | CQ34010 | Écrou hexagonal | 2 |

| 5 | Q1841075 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

| 6 | Q1841020 | Boulon à bride hexagonale, tige grossière (Modèle standard) | 2 |

Les spécifications pour le Filtre fin à carburant FAW se définissent par sa fonction de protection finale du Common Rail Haute Pression (Hpcr) système d'injection. L'ensemble Filtre fin à carburant FAW l'assemblage est un élément essentiel.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Filtre fin à carburant FAW |

| Assemblage complet P/N | 1117010-81D |

| Base permanente Réf. | 1117020-81D (Tête de filtre / Base) |

| Élément réparable P/N | 1117050-81D (Cartouche rotative) |

| Système de montage | Support monté sur châssis (1117120-81D) |

| Fonction principale | Filtration des microparticules (Élimination des abrasifs) |

| Fonction secondaire | Séparation de l'eau (Coalescence) |

| Système protégé | Rail commun haute pression (Hpcr) Pompe et Injecteurs |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.