Différentiel d'essieu arrière russe FAW: Synchronisation 13 Composantes stratégiques pour un maximum de 6×6 Traction

Le Différentiel d'essieu arrière russe FAW serves as the kinetic heart of the rear drive system in the CA3250P66K24L1TE5Z dump truck. Situated deep within the rear axle housing, this intricate mechanism is responsible for distributing torque between the left and right rear wheels while allowing for necessary speed variations during turning maneuvers. Dans la toundra gelée impitoyable de la Fédération de Russie, où la traction détermine la différence entre un transport réussi et un véhicule bloqué, ce différentiel doit convertir un couple élevé en puissance au sol contrôlable. Ce guide complet déconstruit le 13 essential components ensuring unyielding performance.

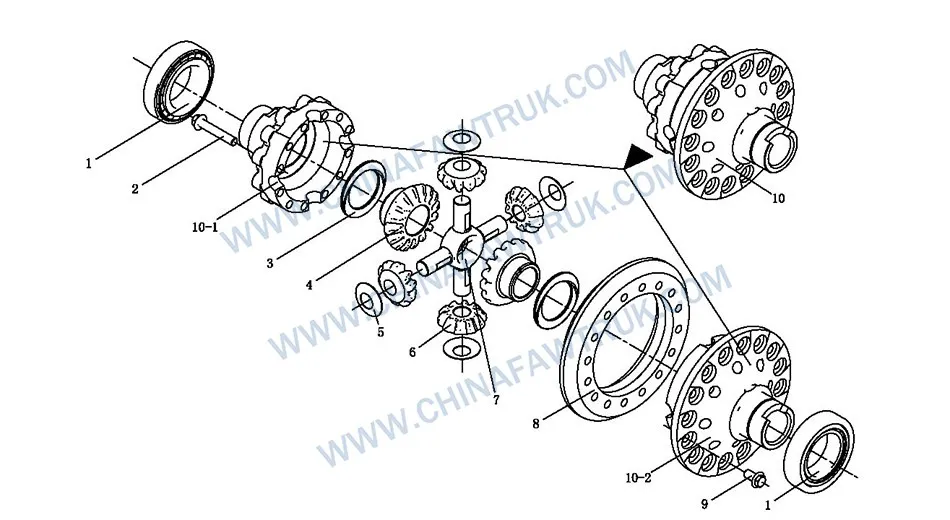

FAW Russian Rear Axle Differential Assembly

Dynamique des engrenages: Le biseau entraîné et le système planétaire

Le principal point d’entrée du couple pour le Différentiel d'essieu arrière russe FAW c'est le massif Engrenage conique entraîné (Partie no. 2402037BA6E). Cette grande couronne s'engrène avec le pignon d'entrée pour créer le rapport de réduction de l'entraînement final. Dans le cadre du camion benne CA3250P66K24L1TE5Z, la métallurgie de cet engrenage est critique. Il agit comme un levier qui multiplie le couple moteur pour faire tourner le lourd boîtier de différentiel.. The specific heat-treatment profile is designed to resist the extreme pitting and shock loads associated with operating in the Russian mining sector, où les roues glissent souvent sur la glace avant de s'agripper soudainement à la roche sèche.

À l'intérieur du transporteur, la répartition du pouvoir est assurée par le “araignée” assemblée, centré autour du Arbre transversal (Partie no. 2403061-A0E). Cet arbre à quatre points supporte le Équipement planétaire unités (Partie no. 2403056-A0E). Alors que le camion tourne, ces engrenages planétaires tournent sur l'arbre transversal, permettant aux roues gauche et droite de tourner à des vitesses différentes. L'usinage de précision des tourillons d'arbre transversal est vital pour le Différentiel d'essieu arrière russe FAW; toute rugosité de surface entraînerait ici une usure rapide des alésages des engrenages planétaires, provoquant un jeu excessif et un éventuel claquement de la transmission.

Les engrenages planétaires engrènent avec le Pignon d'arbre d'essieu (Partie no. 2403051-A0E), également connu sous le nom d'engrenages latéraux. Ces engrenages cannelés se connectent directement aux arbres d'essieu, transmettre la force motrice finale aux roues. Dans le Différentiel d'essieu arrière russe FAW, le profil des dents de ces engrenages latéraux est optimisé pour une zone de contact maximale. Cette conception minimise le risque de fracture dentaire lors de démarrages à couple élevé, un scénario courant lorsqu'un camion entièrement chargé tente de gravir une pente pour sortir d'une fosse boueuse. L'interaction entre les engrenages planétaires et les engrenages de l'arbre d'essieu crée l'action différentielle qui est la fonction essentielle de l'ensemble..

Logique du logement: L'assemblage du boîtier différentiel

L'encapsulation du train d'engrenages est la Assemblage du boîtier différentiel (Partie no. 2403015AA0E). Ce boîtier rigide est une conception divisée, composé du Boîtier gauche – Différentiel (Partie no. 2403017AA0E) et le Bon cas – Différentiel (Partie no. 2403018-A0E). La rigidité structurelle de ce boîtier est primordiale pour le Différentiel d'essieu arrière russe FAW. Sous charge, les engrenages à l'intérieur essaient de se séparer; le boîtier doit contenir ces forces de séparation sans fléchir. Si l'affaire déforme, l'alignement de l'engrenage est perdu, conduisant à un échec catastrophique.

Les moitiés du boîtier sont usinées à partir de fonte nodulaire de haute qualité ou d'acier moulé, choisis pour leur ductilité supérieure à basse température. Dans l'Arctique russe, la fonte standard peut devenir cassante et se fissurer sous l'impact. Le matériau utilisé dans le Différentiel d'essieu arrière russe FAW le boîtier garantit qu'il conserve sa solidité même à -40°C. Les surfaces de contact des boîtiers gauche et droit sont rectifiées avec précision pour garantir une étanchéité et un alignement parfaits, empêchant les fuites d'huile et assurant une rotation concentrique des composants internes.

La fixation des deux moitiés du boîtier ensemble nécessite des attaches à haute résistance. L'assemblage utilise plusieurs unités de Boulon – Fixation du boîtier différentiel (Partie no. 2403023-A0E). Ces boulons ne sont pas simplement serrés; ils sont serrés pour céder et comportent souvent des composés de freinage fileté pré-appliqués. Le Différentiel d'essieu arrière russe FAW s'appuie sur la force de serrage de ces boulons pour maintenir l'unité structurelle du boîtier de différentiel tournant à des régimes élevés. Un boulon desserré ici serait désastreux, détruire le carter d'essieu de l'intérieur vers l'extérieur.

Contrôle de l'usure: Rondelles et cales

Dans le différentiel en rotation, la friction métal sur métal est l'ennemi. Le Différentiel d'essieu arrière russe FAW utilise des rondelles de butée spécifiques pour gérer cette usure. Le Machine à laver – Équipement planétaire (Partie no. 2403058A31) est une rondelle sphérique qui se place entre l'engrenage planétaire et le carter de différentiel. Il absorbe la force centrifuge poussant l'engrenage vers l'extérieur et fournit une surface d'usure sacrificielle. Sans ces rondelles, les engrenages broyeraient directement dans le boîtier en fer, le ruiner.

De la même manière, le Machine à laver – Pignon d'arbre d'essieu (Partie no. 2403053-A0E) est positionné derrière les engrenages latéraux. Ces rondelles de butée plates gèrent les forces de séparation générées par le maillage de l'engrenage conique. Dans l'application intensive du Différentiel d'essieu arrière russe FAW, ces rondelles sont souvent fabriquées à partir d'alliages de bronze ou d'acier trempé avec des rainures d'huile pour favoriser la lubrification hydrodynamique. Assurer un film d'huile continu par temps extrêmement froid est essentiel pour éviter le grippage et le grippage..

L'épaisseur de ces rondelles joue également un rôle dans le réglage du jeu interne de l'engrenage.. Le Différentiel d'essieu arrière russe FAW nécessite un jeu précis pour fonctionner correctement. Trop de cils entraîne des claquements et des charges de choc; trop peu provoque un grippage et une surchauffe. Pendant l'assemblage ou la reconstruction, selecting the correct washer thickness is a precision task that defines the smoothness and longevity of the entire rear axle system.

Logique de rotation: Roulements et fixations

Soutenant l'ensemble du carter de différentiel lorsqu'il tourne à l'intérieur du carter d'essieu, se trouvent les Roulement à rouleaux coniques unités (Partie no. 32216/Ya6). Ces roulements sont soumis à des charges combinées: le poids radial de l'ensemble différentiel et la poussée axiale générée par le maillage anneau-pignon. Le “Ya6” Le suffixe désigne probablement un jeu interne spécifique ou un matériau de cage optimisé pour le Différentiel d'essieu arrière russe FAW. Une précharge correcte sur ces roulements est essentielle pour empêcher le support de fléchir sous la charge..

La fixation de la couronne dentée au carter de différentiel est le joint de fixation le plus critique de tout l'essieu.. L'Assemblée utilise 16 unités de Boulon – Fixation du boîtier gauche du différentiel et du pignon conique entraîné (Partie no. 2402063AA0E) à cet effet. Ces boulons doivent transmettre tout le couple moteur du moteur. Dans le Différentiel d'essieu arrière russe FAW, ces boulons sont généralement conçus avec une tête à bride pour répartir la pression et sont installés avec une séquence couple-angle spécifique.

Si ces boulons devaient se desserrer, la couronne vacillerait, destroying the pinion gear and potentially locking the rear wheels. L'ingénierie robuste du Différentiel d'essieu arrière russe FAW les fixations garantissent que cette connexion reste solide pendant toute la durée de vie du véhicule, même sous les cycles d'arrêt et de démarrage pénibles d'un camion minier. La science des matériaux derrière ces boulons donne la priorité à une résistance élevée à la traction et aux forces de cisaillement..

Répartition des composants: 134. Rear Axle Differential Assembly (je=1.500)

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| – | 2403010BA6E | Assemblage différentiel | 1 |

| 1 | 32216/Ya6 | Roulement à rouleaux coniques | 2 |

| 2 | 2403023-A0E | Boulon – Fixation du boîtier différentiel | 12 |

| 3 | 2403053-A0E | Machine à laver – Pignon d'arbre d'essieu | 2 |

| 4 | 2403051-A0E | Pignon d'arbre d'essieu | 2 |

| 5 | 2403058A31 | Machine à laver – Équipement planétaire | 4 |

| 6 | 2403056-A0E | Équipement planétaire | 4 |

| 7 | 2403061-A0E | Arbre transversal | 1 |

| 8 | 2402037BA6E | Engrenage conique entraîné | 1 |

| 9 | 2402063AA0E | Boulon – Fixation du boîtier gauche du différentiel et du pignon conique entraîné | 16 |

| 10 | 2403015AA0E | Assemblage du boîtier différentiel (Ensemble) | 1 |

| 10-1 | 2403018-A0E | Bon cas – Différentiel | 1 |

| 10-2 | 2403017AA0E | Boîtier gauche – Différentiel | 1 |

Conclusion: The Core of Rear Traction

Le Différentiel d'essieu arrière russe FAW est le composant déterminant qui permet au CA3250P66K24L1TE5Z de fonctionner efficacement dans les conditions extrêmes du nord de la Russie.. Sa conception robuste, avec des matériaux de boîtier résistants au froid, engrenages usinés avec précision, et des composants d'usure durables, ensures that the rear wheels contribute meaningful traction when it matters most. Chaque partie, de l'arbre transversal aux boulons de verrouillage, joue un rôle essentiel dans cette synergie.

Pour les équipes de maintenance, la leçon est une leçon de précision et de qualité. Reconstruire un différentiel est une tâche complexe où les tolérances se mesurent en centièmes de millimètre. L'utilisation d'engrenages ou de roulements génériques risque une défaillance catastrophique pouvant immobiliser le camion.. En investissant dans l'authentique Différentiel d'essieu arrière russe FAW trousse, operators ensure that their vehicle’s rear drive system remains a reliable asset, capable de conquérir les terrains les plus difficiles que la planète a à offrir.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.