Pare-soleil avant russe FAW: Intégration 3 Composants optiques stratégiques pour une navigation arctique sans éblouissement

Le Pare-soleil avant russe FAW Le système est un bouclier optique spécialisé conçu pour le camion-benne FAW CA3250P66K24L1TE5Z.. Dans les opérations de haute latitude du secteur minier russe, lumière du soleil à faible angle et réflexion intense de la couverture neigeuse (effet albédo) créer des conditions aveuglantes qui compromettent la sécurité. Cet assemblage sert de barrière critique, filtre les rayons UV nocifs et réduit l’éblouissement sans obstruer le champ de vision principal du conducteur. En utilisant le Pare-soleil avant russe FAW, les opérateurs peuvent maintenir leur acuité visuelle et réduire la fatigue oculaire pendant les longs quarts de travail en pleine nature, environnement lumineux de la toundra arctique.

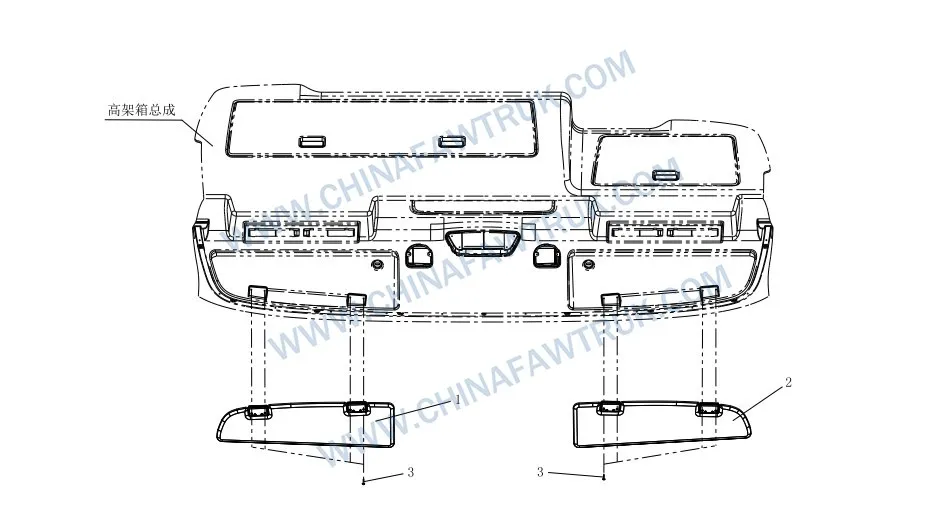

Pare-soleil avant russe FAW

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

8204015-A01 |

Assemblage de visière du soleil avant gauche |

1 |

| 2 |

8204020-A01 |

Assemblage de visière du soleil avant droit |

1 |

| 3 |

CQ2714819F6 |

Vis taraudeuse à tête cylindrique à empreinte cruciforme |

8 |

Génie optique et science des matériaux

La fonctionnalité de base du Pare-soleil avant russe FAW repose sur les propriétés matérielles du Assemblage de visière du soleil avant gauche (Partie no. 8204015-A01) et son homologue. Contrairement aux visières automobiles standard qui utilisent du carton ou du vinyle opaque, le Pare-soleil avant russe FAW utilise un semi-transparent, polymère teinté fumé. Ce matériau est généralement un mélange de polycarbonate ou d'acrylique de haute qualité., conçu pour filtrer des longueurs d'onde spécifiques de lumière bleue de haute intensité qui prévalent dans les environnements enneigés. Cette capacité de filtration est essentielle pour prévenir “cécité des neiges,” une condition dans laquelle la rétine est submergée par le rayonnement UV réfléchi par la glace.

Le Assemblage de visière du soleil avant droit (Partie no. 8204020-A01) reflète cette technologie pour le côté passager. Dans le cadre du camion benne CA3250, qui fonctionne souvent avec un copilote ou un observateur, fournir une protection optique égale est un mandat de sécurité. Le polymère utilisé dans le Assemblage de visière du soleil avant droit est formulé avec des modificateurs d'impact pour rester ductile à des températures aussi basses que -50°C. Les plastiques standards subissent souvent une transition vitreuse dans le froid arctique, devenir cassant et se briser au moindre impact ou vibration. Le Pare-soleil avant russe FAW les composants sont conçus pour fléchir plutôt que de se briser, assurer la longévité dans le rude climat russe.

En outre, la surface des deux Assemblage de visière du soleil avant gauche et le Assemblage de visière du soleil avant droit dispose d'un revêtement dur résistant aux rayures. Les environnements miniers sont remplis de poussière abrasive, et les conducteurs ajustent fréquemment les visières avec des mains gantées qui peuvent être couvertes de gravier. Sans cette couche protectrice, le Pare-soleil avant russe FAW deviendrait vite flou, diffuser la lumière au lieu de la bloquer, ce qui augmenterait paradoxalement l'éblouissement. Cette attention portée à l'ingénierie des surfaces microscopiques met en évidence la différence entre un accessoire générique et un véritable composant FAW pour temps froid..

Stabilité aérodynamique et montage structurel

Bien qu'il s'agisse avant tout d'un appareil optique, le Pare-soleil avant russe FAW remplit également une fonction aérodynamique. Monté à l'extérieur au-dessus du pare-brise, le Assemblage de visière du soleil avant gauche agit comme un bord d'attaque qui adoucit le flux d'air passant du pare-brise à la ligne de toit. Cette réduction des turbulences permet de minimiser le bruit du vent entrant dans la cabine, qui contribue grandement à la fatigue des conducteurs pendant les transports en commun. Le profil du Pare-soleil avant russe FAW est testé en soufflerie pour garantir qu'il ne crée pas de traînée ou de vibrations excessives à grande vitesse.

L'intégrité structurelle du Assemblage de visière du soleil avant droit est tout aussi important. Être un composant externe, il est soumis à des charges de vent importantes, forte accumulation de neige, et l'impact physique des branches d'arbres sur les routes d'accès étroites. Les points de montage du Pare-soleil avant russe FAW sont renforcés pour répartir ces charges sur le rail supérieur structurel de la cabine. Un défaut dans la conception de montage pourrait entraîner le détachement de la visière pendant la conduite., créer un projectile dangereux. Donc, l'interface entre le Assemblage de visière du soleil avant droit et la carrosserie du véhicule est un carrefour de sécurité critique.

Pour lutter contre les vibrations, le Assemblage de visière du soleil avant gauche intègre souvent des joints d'isolation en caoutchouc ou des amortisseurs aux points de fixation. Ceux-ci empêchent les vibrations à haute fréquence du moteur diesel de se transmettre à la vitre de la visière.. Si on le laisse vibrer, le Pare-soleil avant russe FAW brouillerait la vision du conducteur et pourrait desserrer ses propres attaches au fil du temps. La conception garantit que la visière reste statiquement rigide par rapport à la ligne des yeux du conducteur., fournissant un bouclier stable contre le soleil du bas Arctique.

Technologie de fixation: L’analyse des vis taraudeuses

La sécurité de l'ensemble Pare-soleil avant russe FAW l'assemblage dépend de huit unités spécifiques du Vis taraudeuse à tête cylindrique à empreinte cruciforme (Partie no. CQ2714819F6). La sélection d'un “Vis taraudeuse” car cette application est délibérée. Contrairement aux vis mécaniques qui nécessitent un écrou pré-fileté, les vis taraudeuses coupent leurs propres filetages dans la tôle du collecteur de la cabine. Cela crée un ajustement serré sans tolérance, qui est exceptionnellement résistant au desserrage vibratoire, une exigence clé pour le Pare-soleil avant russe FAW dans des conditions hors route.

Le “Croix encastrée” conception de la tête, communément appelé Phillips, permet l'auto-centrage de l'outil d'installation. Ceci est crucial lors de l'installation du Assemblage de visière du soleil avant gauche sur une chaîne de montage ou dans un atelier de terrain. Il empêche l'embout de glisser et de rayer la surface délicate de la visière ou la peinture du véhicule.. Le “Tête panoramique” profil du Vis taraudeuse à tête cylindrique à empreinte cruciforme fournit une surface d'appui plate sous la tête. Cela répartit uniformément la charge de serrage sur les languettes de montage en plastique du Pare-soleil avant russe FAW, empêchant le plastique de se fissurer sous l'effet du couple.

Enfin, le “F6” suffixe dans le numéro de pièce Vis taraudeuse à tête cylindrique à empreinte cruciforme indique un traitement de surface spécialisé, probablement un revêtement en dispersion de flocons de zinc. Dans le milieu russe, les sels de déneigement et l'humidité sont omniprésents. Une vis standard rouillerait rapidement, provoquant des stries disgracieuses sur la cabine et potentiellement grippant le métal. Le revêtement résistant à la corrosion garantit que le Vis taraudeuse à tête cylindrique à empreinte cruciforme reste utilisable, permettant à la Pare-soleil avant russe FAW to be removed for windshield replacement or body repair without the need to drill out stripped fasteners.

Installation Protocols and Maintenance

Installation du Pare-soleil avant russe FAW requires adherence to specific torque protocols. Parce que le Assemblage de visière du soleil avant gauche is secured directly into the sheet metal using the Vis taraudeuse à tête cylindrique à empreinte cruciforme, over-tightening can strip the hole, rendering the mounting point useless. Mechanics must set their clutches to the specified torque limit to ensure a secure hold without compromising the cab structure. This precision ensures that the Pare-soleil avant russe FAW remains firmly attached even during severe chassis articulation.

Un bon alignement du Assemblage de visière du soleil avant droit during installation is also critical. If the visor is mounted under tension or slightly askew, the cold-weather contraction of the material can lead to stress cracks developing around the mounting holes. La conception du Pare-soleil avant russe FAW includes slotted mounting holes to allow for minor adjustments, ensuring a stress-free fit. This consideration for thermal expansion and contraction is a hallmark of the engineering behind the Pare-soleil avant russe FAW système.

Entretien du Pare-soleil avant russe FAW involves regular visual inspections of the Vis taraudeuse à tête cylindrique à empreinte cruciforme unités. While the F6 coating provides protection, physical damage from gravel can compromise it. Any sign of rust should be addressed immediately to prevent galvanic corrosion spreading to the cab roof. En outre, le Assemblage de visière du soleil avant gauche should be cleaned only with mild soap and water; harsh solvents can degrade the UV-protective coating and cause the polymer to craze, reducing the optical clarity of the Pare-soleil avant russe FAW.

Conclusion: A Shield Against the Elements

Le Pare-soleil avant russe FAW est un composant trompeur; simple in appearance but complex in its engineering requirements for the Arctic. It combines the optical precision of the Assemblage de visière du soleil avant gauche et Assemblage de visière du soleil avant droit with the mechanical reliability of the Vis taraudeuse à tête cylindrique à empreinte cruciforme to create a robust safety system. This assembly protects the driver’s vision, reduces fatigue, and contributes to the overall aerodynamic efficiency of the vehicle.

Pour les gestionnaires de flotte, understanding the material science and fastening technology behind the Pare-soleil avant russe FAW underscores the importance of using genuine parts. A generic replacement made of inferior plastic will shatter in the cold, and standard screws will rust. En maintenant le Pare-soleil avant russe FAW avec des composants authentiques, operators ensure that their trucks remain safe and operational, conquering the glare and the cold of the Russian North with unwavering reliability.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.