FAW Russian Front Sun Visor: Integrating 3 Strategic Optical Components for Glare-Free Arctic Navigation

The FAW Russian Front Sun Visor system is a specialized optical shield engineered for the FAW CA3250P66K24L1TE5Z dump truck. In the high-latitude operations of the Russian mining sector, low-angle sunlight and intense reflection from snow cover (albedo effect) create blinding conditions that compromise safety. This assembly serves as a critical barrier, filtering harmful UV radiation and reducing glare without obstructing the driver’s primary field of view. By utilizing the FAW Russian Front Sun Visor, operators can maintain visual acuity and reduce eye fatigue during long shifts in the stark, bright environment of the Arctic tundra.

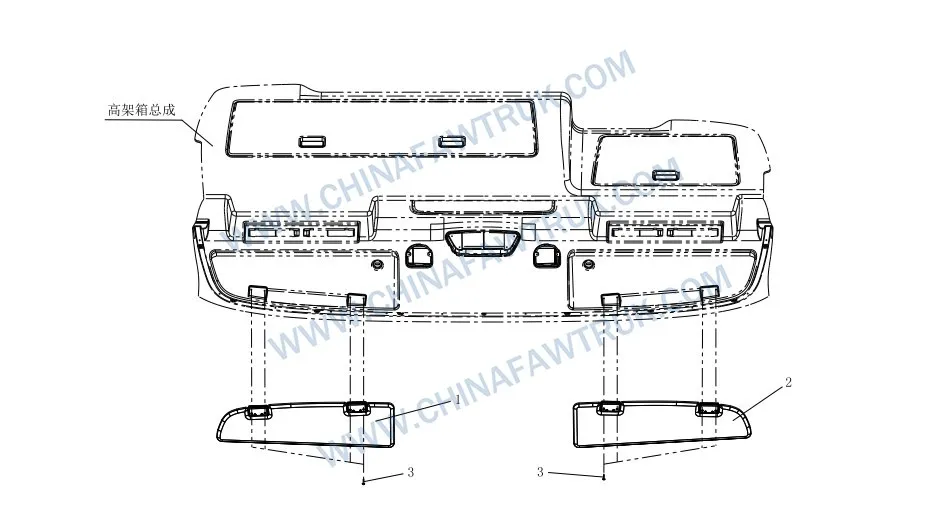

FAW Russian Front Sun Visor

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8204015-A01 |

Left Front Sun Visor Assembly |

1 |

| 2 |

8204020-A01 |

Right Front Sun Visor Assembly |

1 |

| 3 |

CQ2714819F6 |

Cross Recessed Pan Head Tapping Screw |

8 |

Optical Engineering and Material Science

The core functionality of the FAW Russian Front Sun Visor relies on the material properties of the Left Front Sun Visor Assembly (Part No. 8204015-A01) and its counterpart. Unlike standard automotive visors that use opaque cardboard or vinyl, the FAW Russian Front Sun Visor utilizes a semi-transparent, smoke-tinted polymer. This material is typically a high-grade polycarbonate or acrylic blend, engineered to filter out specific wavelengths of high-intensity blue light which are prevalent in snowy environments. This filtration capability is critical for preventing “snow blindness,” a condition where the retina is overwhelmed by UV radiation reflecting off the ice.

The Right Front Sun Visor Assembly (Part No. 8204020-A01) mirrors this technology for the passenger side. In the context of the CA3250 dump truck, which often operates with a co-driver or spotter, providing equal optical protection is a safety mandate. The polymer used in the Right Front Sun Visor Assembly is formulated with impact modifiers to remain ductile at temperatures as low as -50°C. Standard plastics often undergo a glass transition in the Arctic cold, becoming brittle and shattering upon the slightest impact or vibration. The FAW Russian Front Sun Visor components are designed to flex rather than fracture, ensuring longevity in the harsh Russian climate.

Furthermore, the surface of both the Left Front Sun Visor Assembly and the Right Front Sun Visor Assembly features a scratch-resistant hard coating. Mining environments are filled with abrasive dust, and drivers frequently adjust the visors with gloved hands that may be covered in grit. Without this protective layer, the FAW Russian Front Sun Visor would quickly become hazy, diffusing light instead of blocking it, which would paradoxically increase glare. This attention to microscopic surface engineering highlights the difference between a generic accessory and a genuine FAW cold-weather component.

Aerodynamic Stability and Structural Mounting

While primarily an optical device, the FAW Russian Front Sun Visor also serves an aerodynamic function. Mounted externally above the windshield, the Left Front Sun Visor Assembly acts as a leading edge that smooths the airflow transitioning from the windshield to the roofline. This reduction in turbulence helps to minimize wind noise entering the cabin, which is a significant contributor to driver fatigue during highway transit. The profile of the FAW Russian Front Sun Visor is wind-tunnel tested to ensure it does not create excessive drag or vibration at speed.

The structural integrity of the Right Front Sun Visor Assembly is equally important. Being an external component, it is subjected to significant wind loads, heavy snow accumulation, and the physical impact of tree branches on narrow access roads. The mounting points of the FAW Russian Front Sun Visor are reinforced to distribute these loads across the cab’s structural header rail. A failure in the mounting design could lead to the visor detaching while driving, creating a dangerous projectile. Therefore, the interface between the Right Front Sun Visor Assembly and the vehicle body is a critical safety junction.

To combat vibration, the Left Front Sun Visor Assembly often incorporates rubber isolation gaskets or dampeners at the attachment points. These prevent the high-frequency vibrations of the diesel engine from transferring to the visor pane. If allowed to vibrate, the FAW Russian Front Sun Visor would blur the driver’s vision and potentially loosen its own fasteners over time. The design ensures that the visor remains statically rigid relative to the driver’s eye line, providing a steady shield against the low Arctic sun.

Fastening Technology: The Tapping Screw Analysis

The security of the entire FAW Russian Front Sun Visor assembly is dependent on eight specific units of the Cross Recessed Pan Head Tapping Screw (Part No. CQ2714819F6). The selection of a “Tapping Screw” for this application is deliberate. Unlike machine screws that require a pre-threaded nut, tapping screws cut their own mating threads into the sheet metal of the cab header. This creates a zero-tolerance interference fit, which is exceptionally resistant to vibrational loosening—a key requirement for the FAW Russian Front Sun Visor in off-road conditions.

The “Cross Recessed” head design, commonly known as Phillips, allows for the self-centering of the installation tool. This is crucial when installing the Left Front Sun Visor Assembly on an assembly line or in a field workshop. It prevents the driver bit from slipping and scratching the delicate surface of the visor or the vehicle paint. The “Pan Head” profile of the Cross Recessed Pan Head Tapping Screw provides a flat bearing surface under the head. This distributes the clamping load evenly over the plastic mounting tabs of the FAW Russian Front Sun Visor, preventing the plastic from cracking under torque.

Finally, the “F6” suffix in the part number Cross Recessed Pan Head Tapping Screw indicates a specialized surface treatment, likely a zinc-flake dispersion coating. In the Russian environment, road salts and moisture are omnipresent. A standard screw would rust quickly, causing unsightly streaks on the cab and potentially seizing in the metal. The corrosion-resistant coating ensures that the Cross Recessed Pan Head Tapping Screw remains serviceable, allowing the FAW Russian Front Sun Visor to be removed for windshield replacement or body repair without the need to drill out stripped fasteners.

Installation Protocols and Maintenance

Installing the FAW Russian Front Sun Visor requires adherence to specific torque protocols. Because the Left Front Sun Visor Assembly is secured directly into the sheet metal using the Cross Recessed Pan Head Tapping Screw, over-tightening can strip the hole, rendering the mounting point useless. Mechanics must set their clutches to the specified torque limit to ensure a secure hold without compromising the cab structure. This precision ensures that the FAW Russian Front Sun Visor remains firmly attached even during severe chassis articulation.

Proper alignment of the Right Front Sun Visor Assembly during installation is also critical. If the visor is mounted under tension or slightly askew, the cold-weather contraction of the material can lead to stress cracks developing around the mounting holes. The design of the FAW Russian Front Sun Visor includes slotted mounting holes to allow for minor adjustments, ensuring a stress-free fit. This consideration for thermal expansion and contraction is a hallmark of the engineering behind the FAW Russian Front Sun Visor system.

Maintenance of the FAW Russian Front Sun Visor involves regular visual inspections of the Cross Recessed Pan Head Tapping Screw units. While the F6 coating provides protection, physical damage from gravel can compromise it. Any sign of rust should be addressed immediately to prevent galvanic corrosion spreading to the cab roof. Furthermore, the Left Front Sun Visor Assembly should be cleaned only with mild soap and water; harsh solvents can degrade the UV-protective coating and cause the polymer to craze, reducing the optical clarity of the FAW Russian Front Sun Visor.

Conclusion: A Shield Against the Elements

The FAW Russian Front Sun Visor is a deceptive component; simple in appearance but complex in its engineering requirements for the Arctic. It combines the optical precision of the Left Front Sun Visor Assembly and Right Front Sun Visor Assembly with the mechanical reliability of the Cross Recessed Pan Head Tapping Screw to create a robust safety system. This assembly protects the driver’s vision, reduces fatigue, and contributes to the overall aerodynamic efficiency of the vehicle.

For fleet managers, understanding the material science and fastening technology behind the FAW Russian Front Sun Visor underscores the importance of using genuine parts. A generic replacement made of inferior plastic will shatter in the cold, and standard screws will rust. By maintaining the FAW Russian Front Sun Visor with authentic components, operators ensure that their trucks remain safe and operational, conquering the glare and the cold of the Russian North with unwavering reliability.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.