Rideaux et écrans russes FAW: Déploiement 5 Barrières essentielles pour une défense sans compromis du système de refroidissement

Le Rideaux et écrans russes FAW logic assembly acts as the frontline shield for the CA3250P66K24L1TE5Z dump truck. Positioned ahead of the delicate radiator fins, this system filters out the destructive debris typical of Siberian mining operations. From frozen slush to abrasive rock dust, this assembly ensures that the cooling stack maintains optimal airflow without sustaining physical damage in -40°C environments.

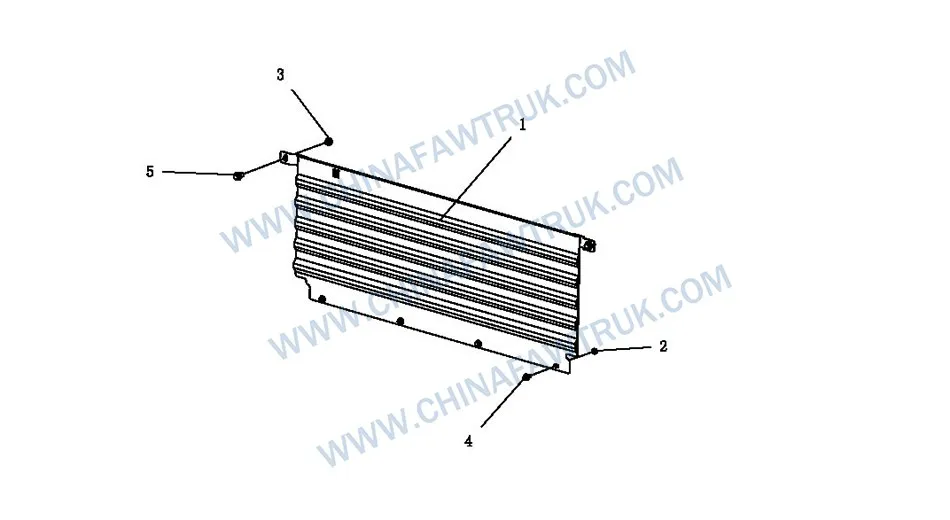

FAW Russian Curtains And Screens Assembly

Defense Dynamics: The Screen Assembly

Au coeur du Rideaux et écrans russes FAW system lies the Screen Assembly (Partie no. 1310050-90U). This component is not merely a cosmetic grille; it is a calibrated filtration device designed to protect the cooling module. Dans l'Arctique russe, heavy trucks often follow one another on unpaved service roads made of crushed rock and ice. The leading vehicles kick up a spray of abrasive slurry and high-velocity stones. Without the intervention of the Rideaux et écrans russes FAW, these projectiles would impact directly onto the aluminum fins of the radiator and intercooler.

Le Screen Assembly functions by intercepting these threats. Its mesh density is engineered to a specific porosity. It must be tight enough to stop stones that are large enough to bend cooling fins, yet open enough not to restrict the airflow required by the engine fan. If the screen is too dense, it acts like a solid wall, provoquant une surchauffe du moteur. If it is too open, it fails to protect. Le Rideaux et écrans russes FAW achieves this balance perfectly, allowing air to pass while capturing damaging debris.

En outre, this assembly plays a role in “winter front” logique. Par grand froid (-40° C), preventing the engine from overcooling is as important as preventing overheating. While primarily a debris shield, le Rideaux et écrans russes FAW creates a slight buffer zone of stagnant air ahead of the radiator. This assists in stabilizing the thermal gradient across the cooling stack during initial warm-up, preventing the thermal shock that occurs when freezing air blasts directly onto hot metal components.

Science des matériaux: Resisting Embrittlement

La construction du Rideaux et écrans russes FAW utilizes materials specifically selected for the Siberian climate. Standard plastic or low-grade steel screens suffer from cold embrittlement. À -40°C, a standard polymer mesh becomes as brittle as glass; a single rock impact would shatter it, sending plastic shards into the radiator it was meant to protect. Le Rideaux et écrans russes FAW assembly employs high-ductility polymers or corrosion-resistant coated steel wire that retains flexibility even in the deep freeze.

Corrosion resistance is equally vital. Russian highways are treated with aggressive de-icing salts and chemical grit to maintain traction. This creates a corrosive mist that coats the front of the vehicle. Le Screen Assembly acts as the first contact point for this corrosive slurry. To ensure longevity, le Rideaux et écrans russes FAW components are treated with advanced electrostatic powder coatings or zinc-flake plating. This prevents rust from compromising the structural integrity of the mesh, ensuring it remains strong enough to deflect rocks year after year.

The frame of the screen is designed to resist vibration fatigue. A dump truck chassis twists and vibrates constantly. A rigid frame would crack at the mounting points. Le Rideaux et écrans russes FAW design incorporates flexible mounting tabs or a compliant frame structure that absorbs these vibrations. This ensures that the screen remains securely attached to the vehicle, maintaining its protective position without rattling or working loose over rough terrain.

Dynamique de fixation: Nuts and Vibration

La sécurité du Rideaux et écrans russes FAW depends on its fastening hardware. The assembly utilizes distinct sizes of nuts: Écrou hexagonal (Partie no. CQ34006) et Écrou hexagonal (Partie no. CQ34008). The use of different sizes (M6 and M8) indicates specific load requirements for different mounting points. Smaller nuts are likely used for securing the mesh to its frame, while larger nuts secure the frame to the chassis. This differentiated logic ensures that clamping forces are appropriate for the materials being joined.

Dans le contexte du Rideaux et écrans russes FAW, these nuts are not generic hardware. They are manufactured to tight tolerance standards to ensure consistent thread engagement. In a high-vibration environment, a loose thread fit leads to self-loosening. Once a nut backs off, the screen begins to rattle. This vibration causes abrasion against the radiator tanks, eventually wearing a hole through the aluminum and causing a coolant leak.

Donc, l'intégrité du Rideaux et écrans russes FAW relies on these nuts maintaining torque. They are often paired with thread-locking compounds or designed with specific metallurgical properties to match the thermal expansion of the bolts they secure. This attention to detail prevents the “cold flow” loosening that can occur when metal fasteners contract in extreme winter temperatures, ensuring the screen stays firmly in place.

Anchoring Strength: Flange Bolt Architecture

To anchor the assembly, le Rideaux et écrans russes FAW system uses Boulon à bride hexagonale à tige grossière (Partie no. Q1840612) et Boulon à bride hexagonale à tige grossière (Partie no. Q1840816). The selection of flange bolts is a deliberate engineering choice for this application. The integrated flange at the base of the hex head acts as a built-in washer. This increases the surface area in contact with the screen frame, distributing the clamping load over a wider zone.

This load distribution is critical for the Rideaux et écrans russes FAW because the screen frame is often made of thinner stamped metal or plastic. A standard bolt head would dig into the material, creating stress risers and potential cracking points. The flange bolt eliminates this risk. En outre, le “Tige grossière” designation refers to the thread pitch. Coarse threads are deeper and more robust than fine threads, making them less susceptible to stripping during installation or cross-threading in difficult field conditions.

In the snowy, muddy conditions of a Russian mine, maintenance is often performed under less-than-ideal circumstances. The robust nature of these bolts ensures that the Rideaux et écrans russes FAW can be removed for radiator cleaning and reinstalled multiple times without thread failure. The bolts are also treated to resist seizing from rust, ensuring that the screen can always be removed when necessary to access the cooling system for service.

Répartition des composants: 96. Curtains and Screens Logic Assembly

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

1310050-90U |

Screen Assembly |

1 |

| 2 |

CQ34006 |

Écrou hexagonal |

4 |

| 3 |

CQ34008 |

Écrou hexagonal |

2 |

| 4 |

Q1840612 |

Boulon à bride hexagonale à tige grossière (Standard) |

4 |

| 5 |

Q1840816 |

Boulon à bride hexagonale à tige grossière (Standard) |

2 |

Conclusion: The First Line of Defense

Le Rideaux et écrans russes FAW assembly is the unsung hero of the cooling system. While simple in appearance, its role in filtering out the hostile environment of a Russian mine is absolute. By sacrificing itself to block rocks, glace, et débris, it ensures that the expensive and critical radiator remains pristine and functional.

Pour les gestionnaires de flotte, le Rideaux et écrans russes FAW is a primary inspection item. A damaged screen is a warning sign; a missing screen is an invitation to disaster. Ensuring that this barrier is intact and securely fastened with the correct flange bolts and nuts is the most cost-effective preventative maintenance measure available. Investing in this genuine protective assembly safeguards the entire thermal management system of the CA3250P66K24L1TE5Z.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.