Bienvenue dans ce guide technique critique sur le Suspension arrière FAW assemblée (Assemblée 509). C'est le complet, robuste “tandem-axle” suspension system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This is the assembly that handles the entire payload and provides traction.

Le Suspension arrière FAW est un “logique” system known as a “balance beam” ou “tourillon” suspension. Its design is critical for a 6×4 tracteur, as it is engineered to articulate and “marcher” over uneven terrain, ensuring all eight rear wheels remain in contact with the ground for maximum traction and load distribution.

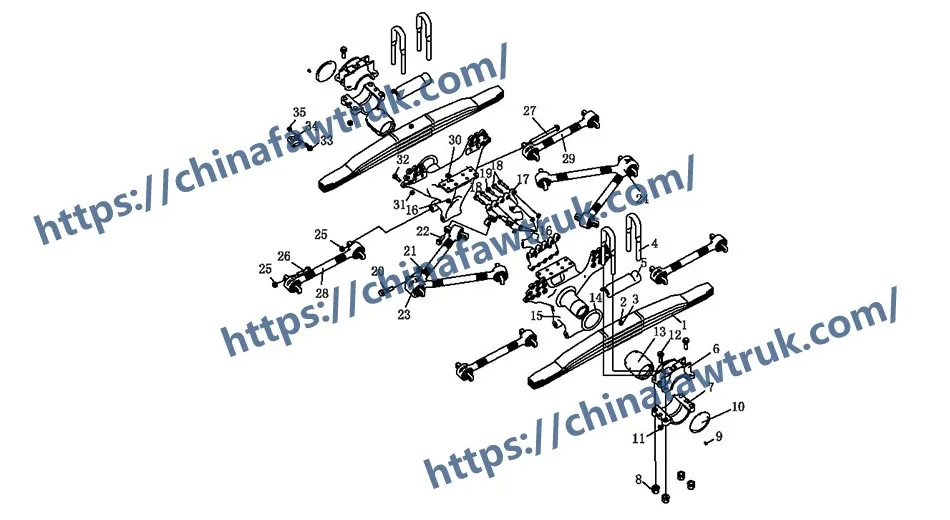

This in-depth guide is an essential resource for professional chassis technicians, gestionnaires de flotte, et spécialistes des pièces détachées. Nous déconstruirons l'ensemble Suspension arrière FAW dans son 35 types de composants réparables, including the ‘Rear leaf spring assembly’, the ‘Balance suspension bracket’, the ‘Thrust rods’, and the vast array of high-tensile fasteners that hold this high-stress system together.

Le coeur du Suspension arrière FAW is the ‘Rear leaf spring assembly’ (2912010-2000). The list calls for two of these—one for each side of the truck. Unlike a front suspension, this is an “inverted” leaf pack. Le “pack” consists of multiple leaves of high-carbon spring steel, such as ‘Rear leaf spring-first leaf’ (2912011-2000) through ‘Rear leaf spring-fourth leaf’ (2912014-2000).

Le “logique” de ceci Suspension arrière FAW is completely different from the front. The center of this spring pack (held by ‘Center bolt-rear leaf spring’ 2912161-70UN) rests on the ‘Balance suspension bracket’ (tourillon), which is the central pivot point on the chassis. The *ends* of the spring pack rest on the two rear drive axles.

Cela crée un “poutre de marche” effet. When the front-most drive axle hits a bump, it pushes *up* on the front of the spring pack; ce, à son tour, forces the *back* of the spring pack *down*, pushing the rear-most drive axle onto the ground. Ce “marche” articulation is the core logic of the Suspension arrière FAW, ensuring constant, maximum traction for both axles.

The central pivot for this “marche” Suspension arrière FAW is the ‘Balance suspension bracket’ assemblée (voir Assemblée 499). This is the heavy-duty bracket that mounts to the truck’s frame rail. The parts in this list are what attach the leaf spring *to* that trunnion.

The ‘Balance suspension bracket pin upper/lower cover’ (2918041-1057, 2918046-1057) and ‘Bushing-balance suspension bracket pin’ (2918042-242) form the “palier” that the leaf spring pack pivots on.

The ‘Cover-balance suspension bracket spring’ (2918072-1050) est le “capuchon” that holds the spring pack down onto this trunnion. Tout cela “logique” assembly is what allows the inverted ‘Rear leaf spring assembly’ to pivot in the center, créant le “walking beam.” This is the most critical pivot point in the entire Suspension arrière FAW.

Le Suspension arrière FAW must not only support weight, but it must also hold the two drive axles in perfect alignment. This is done by two systems.

**1. Boulons en U:** The ‘U-bolt-fasten rear leaf spring’ (2912411-70UN) unités (4 total) are what “serrer” the axles *to* the ends of the leaf spring packs. They pass through the ‘Cover-rear leaf spring’ (2912406-1057) and are secured by the eight ‘Nut-fasten U-bolt’ (2912413-5H). This is the primary vertical connection.

**2. Thrust Rods:** Leaf springs are not strong enough to handle the immense acceleration and braking torque (which tries to “twist” the axle). C'est le travail du “tige de poussée” (ou “torque rod”) système. Ce Suspension arrière FAW parts list includes the ‘Upper front/rear connecting rod with rubber bushing’ (2919005-242, 2919015-242) and the ‘Lower front/rear connecting rod with rubber bushing’ (2919010-242, 2919020-242).

Ce “logique” crée un “four-link” system for each axle. These four rods (two upper, two lower) form a rigid “boîte” that connects the axle directly to the frame, forcing it to stay perfectly aligned. The ‘Support-upper reaction rod and vehicle frame connecting’ (2919111-2000) is the chassis-side bracket for these rods. This thrust rod system is the “logique” that handles all the acceleration and braking forces, leaving the Suspension arrière FAW leaf springs to simply handle the vertical load.

Le Suspension arrière FAW is a high-stress, high-vibration assembly held together by over 100 specialized fasteners. A single failed bolt here could be catastrophic.

**SPL Self-Locking Nuts (T327-series):** The parts list calls for a total of **52** ‘SPL hex small flange lock nuts’ (T32718TF2, T32720TF2, T32724TF2). C'est le “logique” of a modern, high-safety Suspension arrière FAW. Ce sont “Stover” ou “couple dominant” contre-écrous. The top of the nut is intentionally crimped or deformed, créer un “elastic” lock that grips the bolt threads. This makes them *immune* to vibration and *must* be used for all critical connections, especially on the thrust rods.

**Flange Bolts (Q185-series):** The list calls for over 40 « Boulons à bride hexagonale’ (Q1851875T, Q1851850T, Q1852060T, Q1852090T, Q1851860T). Le “bride” head acts as an integrated washer to spread the clamping load. Le “T” suffix denotes a high-tensile (Par exemple, 10.9) force, essential for handling the shear forces of the Suspension arrière FAW.

**Flange Nuts (C039714):** Le 12 ‘Hex flange nuts’ provide a wide, secure clamping base for other non-locking-nut applications. This comprehensive, over-engineered fastener set is the “logique” qui assure la Suspension arrière FAW stays intact under the most extreme conditions.

Le tableau suivant présente la première partie de la répartition détaillée des Suspension arrière FAW (509) schéma du tracteur FAW CA4251P66K24T1A3E5.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 2912010-2000 | Ensemble de ressort à lames arrière | 2 |

| 2912011-2000 | Rear leaf spring-first leaf | 2 | |

| 2912012-2000 | Rear leaf spring-second leaf | 2 | |

| 2912013-2000 | Rear leaf spring-third leaf | 2 | |

| 2912014-2000 | Rear leaf spring-fourth leaf | 2 | |

| 2912211-70UN | Joint-ressort à lames arrière | 8 | |

| 2 | 2912161-70UN | Boulon central-ressort à lames arrière | 2 |

| 3 | CQ34116 | Écrou hexagonal | 2 |

| 4 | 2912411-70UN | U-bolt-fasten rear leaf spring | 4 |

| 5 | 2912406-1057 | Ressort à lames arrière | 2 |

| 6 | 2918041-1057 | Balance suspension bracket pin upper cover | 2 |

| 7 | 2918046-1057 | Balance suspension bracket pin lower cover | 2 |

| 8 | 2912413-5H | Boulon en U à fixer par écrou | 8 |

| 9 | C01500812 | Boulon à tête hexagonale | 2 |

| 10 | 2918072-1050 | Cover-balance suspension bracket spring | 2 |

| 11 | T32720TF2 | SPL hex small flange lock nut | 4 |

| 12 | Q1852075T | Boulon à bride à tête hexagonale | 2 |

| 13 | 2918042-242 | Bushing-balance suspension bracket pin | 4 |

| 14 | 2918017-2000 | Bague (selon l'échantillon) | 2 |

| 15 | 2918016-2000 | Bracket-balance suspension | 2 |

Ce tableau détaille les composants restants pour le Suspension arrière FAW, focusing on the thrust rod system and fasteners.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 16 | T32718TF2 | SPL hex small flange lock nut | 32 |

| 17 | 2919111-2000 | Support-upper reaction rod and vehicle frame connecting | 2 |

| 18 | Q1851875T | Boulon à bride à tête hexagonale | 16 |

| 19 | Q1851850T | Boulon à bride à tête hexagonale | 4 |

| 20 | Q1851850T | Boulon à bride à tête hexagonale | 4 |

| 21 | T32724TF2 | SPL hex small flange lock nut | 4 |

| 22 | Q1852060T | Boulon à bride à tête hexagonale | 8 |

| 23 | 2919005-242 | Upper front reaction rod with rubber bushing assy | 1 |

| 24 | 2919015-242 | Upper rear reaction rod with rubber bushing assy | 1 |

| 25 | T32720TF2 | SPL hex small flange lock nut | 12 |

| 26 | Q1852090T | Boulon à bride à tête hexagonale | 8 |

| 27 | Q1852090T | Boulon à bride à tête hexagonale | 4 |

| 28 | 2919010-242 | Lower front reaction rod with rubber bushing assy | 2 |

| 29 | 2919020-242 | Lower rear reaction rod with rubber bushing assy | 2 |

| 30 | Q1851860T | Boulon à bride à tête hexagonale | 16 |

| 31 | T32716TF2 | SPL hex small flange lock nut | 40 |

| 32 | Q1851655T | Boulon à bride à tête hexagonale | 40 |

| 33 | C039714 | Écrou à bride hexagonale | 12 |

| 34 | 2912433-2000 | Limit stop bracket-rear leaf spring | 4 |

| 35 | Q1851450T | Boulon à bride à tête hexagonale | 12 |

Les spécifications pour le Suspension arrière FAW sont définis par sa fonction de poids lourd, tandem-axle “poutre de marche” suspension. Le Suspension arrière FAW is a comprehensive system for load-bearing and traction.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Suspension arrière FAW |

| Type de suspension | Tandem Axle, Inverted Multi-Leaf Spring (“Walking Beam”) |

| Assemblage du ressort principal | 2x (Partie no. 2912010-2000) |

| Montage sur essieu | 4x boulons en U (2912411-70UN), 2x Couvertures (2912406-1057) |

| Central Pivot | 2x ‘Balance suspension bracket’ (2918016-2000) (Trunnion) |

| Torque Control System | Thrust Rods (Upper/Lower, Front/Rear – 2919xxx series) |

| Thrust Rod Brackets | 2x ‘Support-upper reaction rod’ (2919111-2000) |

| Attaches critiques | 84x SPL Lock Nuts (T327-series), 100+ Boulons à bride hexagonale |

| Fonction principale | To support the entire rear-axle load while allowing for axle articulation (“marche”) to maintain traction. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.