Bienvenido a esta guía técnica crítica sobre la Suspensión trasera FAW asamblea (Asamblea 509). este es el completo, trabajo pesado “tandem-axle” suspension system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. This is the assembly that handles the entire payload and provides traction.

El Suspensión trasera FAW es un “lógica” system known as a “balance beam” o “muñón” suspensión. Its design is critical for a 6×4 tractor, as it is engineered to articulate and “caminar” over uneven terrain, ensuring all eight rear wheels remain in contact with the ground for maximum traction and load distribution.

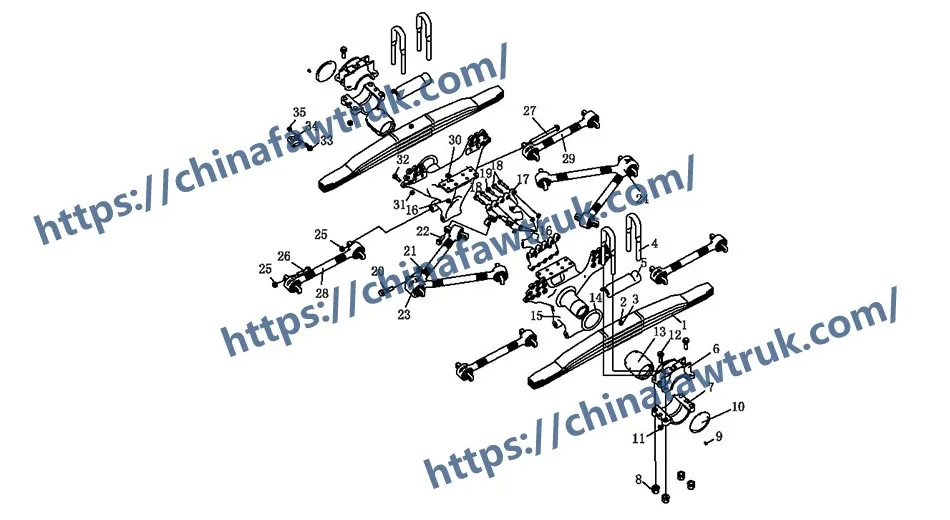

Esta guía detallada es un recurso esencial para los técnicos de chasis profesionales., administradores de flotas, y especialistas en repuestos. Deconstruiremos todo Suspensión trasera FAW en su 35 tipos de componentes reparables, including the ‘Rear leaf spring assembly’, the ‘Balance suspension bracket’, the ‘Thrust rods’, and the vast array of high-tensile fasteners that hold this high-stress system together.

El corazón de la Suspensión trasera FAW is the ‘Rear leaf spring assembly’ (2912010-2000). The list calls for two of these—one for each side of the truck. Unlike a front suspension, this is an “inverted” leaf pack. El “embalar” consists of multiple leaves of high-carbon spring steel, such as ‘Rear leaf spring-first leaf’ (2912011-2000) through ‘Rear leaf spring-fourth leaf’ (2912014-2000).

El “lógica” de esto Suspensión trasera FAW is completely different from the front. The center of this spring pack (held by ‘Center bolt-rear leaf spring’ 2912161-70A) rests on the ‘Balance suspension bracket’ (muñón), which is the central pivot point on the chassis. The *ends* of the spring pack rest on the two rear drive axles.

Esto crea un “viga para caminar” efecto. When the front-most drive axle hits a bump, it pushes *up* on the front of the spring pack; este, Sucesivamente, forces the *back* of the spring pack *down*, pushing the rear-most drive axle onto the ground. Este “caminando” articulation is the core logic of the Suspensión trasera FAW, ensuring constant, maximum traction for both axles.

The central pivot for this “caminando” Suspensión trasera FAW is the ‘Balance suspension bracket’ asamblea (ver montaje 499). This is the heavy-duty bracket that mounts to the truck’s frame rail. The parts in this list are what attach the leaf spring *to* that trunnion.

The ‘Balance suspension bracket pin upper/lower cover’ (2918041-1057, 2918046-1057) and ‘Bushing-balance suspension bracket pin’ (2918042-242) formar el “cojinete” that the leaf spring pack pivots on.

The ‘Cover-balance suspension bracket spring’ (2918072-1050) es el “tapa” that holds the spring pack down onto this trunnion. todo esto “lógica” assembly is what allows the inverted ‘Rear leaf spring assembly’ to pivot in the center, creando el “walking beam.” This is the most critical pivot point in the entire Suspensión trasera FAW.

El Suspensión trasera FAW must not only support weight, but it must also hold the two drive axles in perfect alignment. This is done by two systems.

**1. Pernos en U:** The ‘U-bolt-fasten rear leaf spring’ (2912411-70A) unidades (4 total) son lo que “abrazadera” the axles *to* the ends of the leaf spring packs. They pass through the ‘Cover-rear leaf spring’ (2912406-1057) and are secured by the eight ‘Nut-fasten U-bolt’ (2912413-5h). This is the primary vertical connection.

**2. Thrust Rods:** Leaf springs are not strong enough to handle the immense acceleration and braking torque (which tries to “girar” el eje). Este es el trabajo del “barra de empuje” (o “torque rod”) sistema. Este Suspensión trasera FAW parts list includes the ‘Upper front/rear connecting rod with rubber bushing’ (2919005-242, 2919015-242) and the ‘Lower front/rear connecting rod with rubber bushing’ (2919010-242, 2919020-242).

Este “lógica” crea un “four-link” system for each axle. These four rods (two upper, two lower) form a rigid “caja” that connects the axle directly to the frame, forcing it to stay perfectly aligned. The ‘Support-upper reaction rod and vehicle frame connecting’ (2919111-2000) is the chassis-side bracket for these rods. This thrust rod system is the “lógica” that handles all the acceleration and braking forces, dejando el Suspensión trasera FAW leaf springs to simply handle the vertical load.

El Suspensión trasera FAW es un alto estrés, high-vibration assembly held together by over 100 sujetadores especializados. A single failed bolt here could be catastrophic.

**SPL Self-Locking Nuts (T327-series):** The parts list calls for a total of **52** ‘SPL hex small flange lock nuts’ (T32718TF2, T32720TF2, T32724TF2). Este es el “lógica” of a modern, high-safety Suspensión trasera FAW. Estos son “Stover” o “par predominante” tuercas de seguridad. The top of the nut is intentionally crimped or deformed, creating an “elastic” lock that grips the bolt threads. This makes them *immune* to vibration and *must* be used for all critical connections, especially on the thrust rods.

**Pernos de brida (Q185-series):** The list calls for over 40 'Pernos de brida hexagonal’ (Q1851875T, Q1851850T, Q1852060T, Q1852090T, Q1851860T). El “brida” head acts as an integrated washer to spread the clamping load. El “t” suffix denotes a high-tensile (P.EJ., 10.9) fortaleza, essential for handling the shear forces of the Suspensión trasera FAW.

**Flange Nuts (C039714):** El 12 ‘Hex flange nuts’ provide a wide, secure clamping base for other non-locking-nut applications. This comprehensive, over-engineered fastener set is the “lógica” que asegura la Suspensión trasera FAW stays intact under the most extreme conditions.

La siguiente tabla proporciona la primera parte del desglose detallado de los Suspensión trasera FAW (509) diagrama para el tractor FAW CA4251P66K24T1A3E5.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 2912010-2000 | Conjunto de resorte de hoja trasera | 2 |

| 2912011-2000 | Rear leaf spring-first leaf | 2 | |

| 2912012-2000 | Rear leaf spring-second leaf | 2 | |

| 2912013-2000 | Rear leaf spring-third leaf | 2 | |

| 2912014-2000 | Rear leaf spring-fourth leaf | 2 | |

| 2912211-70A | Spring de la hoja de la junta-cría | 8 | |

| 2 | 2912161-70A | Resorte de hoja de perno de perno central | 2 |

| 3 | CQ34116 | Nuez hexagonal | 2 |

| 4 | 2912411-70A | U-bolt-fasten rear leaf spring | 4 |

| 5 | 2912406-1057 | Spring de hoja de tope | 2 |

| 6 | 2918041-1057 | Balance suspension bracket pin upper cover | 2 |

| 7 | 2918046-1057 | Balance suspension bracket pin lower cover | 2 |

| 8 | 2912413-5h | Perno en U con tuerca | 8 |

| 9 | C01500812 | Perno de cabeza hexagonal | 2 |

| 10 | 2918072-1050 | Cover-balance suspension bracket spring | 2 |

| 11 | T32720TF2 | SPL hex small flange lock nut | 4 |

| 12 | Q1852075T | Perno de brida de cabeza hexagonal | 2 |

| 13 | 2918042-242 | Bushing-balance suspension bracket pin | 4 |

| 14 | 2918017-2000 | Cojinete (según muestra) | 2 |

| 15 | 2918016-2000 | Bracket-balance suspension | 2 |

Esta tabla detalla los componentes restantes para el Suspensión trasera FAW, focusing on the thrust rod system and fasteners.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 16 | T32718TF2 | SPL hex small flange lock nut | 32 |

| 17 | 2919111-2000 | Support-upper reaction rod and vehicle frame connecting | 2 |

| 18 | Q1851875T | Perno de brida de cabeza hexagonal | 16 |

| 19 | Q1851850T | Perno de brida de cabeza hexagonal | 4 |

| 20 | Q1851850T | Perno de brida de cabeza hexagonal | 4 |

| 21 | T32724TF2 | SPL hex small flange lock nut | 4 |

| 22 | Q1852060T | Perno de brida de cabeza hexagonal | 8 |

| 23 | 2919005-242 | Upper front reaction rod with rubber bushing assy | 1 |

| 24 | 2919015-242 | Upper rear reaction rod with rubber bushing assy | 1 |

| 25 | T32720TF2 | SPL hex small flange lock nut | 12 |

| 26 | Q1852090T | Perno de brida de cabeza hexagonal | 8 |

| 27 | Q1852090T | Perno de brida de cabeza hexagonal | 4 |

| 28 | 2919010-242 | Lower front reaction rod with rubber bushing assy | 2 |

| 29 | 2919020-242 | Lower rear reaction rod with rubber bushing assy | 2 |

| 30 | Q1851860T | Perno de brida de cabeza hexagonal | 16 |

| 31 | T32716TF2 | SPL hex small flange lock nut | 40 |

| 32 | Q1851655T | Perno de brida de cabeza hexagonal | 40 |

| 33 | C039714 | Tuerca con brida hexagonal | 12 |

| 34 | 2912433-2000 | Limit stop bracket-rear leaf spring | 4 |

| 35 | Q1851450T | Perno de brida de cabeza hexagonal | 12 |

Las especificaciones para el Suspensión trasera FAW se definen por su función como pesado, tandem-axle “viga para caminar” suspensión. El Suspensión trasera FAW is a comprehensive system for load-bearing and traction.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Suspensión trasera FAW |

| Suspension Type | Tandem Axle, Inverted Multi-Leaf Spring (“Walking Beam”) |

| Conjunto de resorte principal | 2incógnita (Número de pieza. 2912010-2000) |

| Montaje del eje | 4x pernos en U (2912411-70A), 2x Cubiertas (2912406-1057) |

| Central Pivot | 2x ‘Balance suspension bracket’ (2918016-2000) (Trunnion) |

| Torque Control System | Thrust Rods (Upper/Lower, Delantero/trasero – 2919xxx series) |

| Thrust Rod Brackets | 2x ‘Support-upper reaction rod’ (2919111-2000) |

| Sujetadores críticos | 84x SPL Lock Nuts (T327-series), 100+ Hex Flange Bolts |

| Función primaria | To support the entire rear-axle load while allowing for axle articulation (“caminando”) to maintain traction. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.