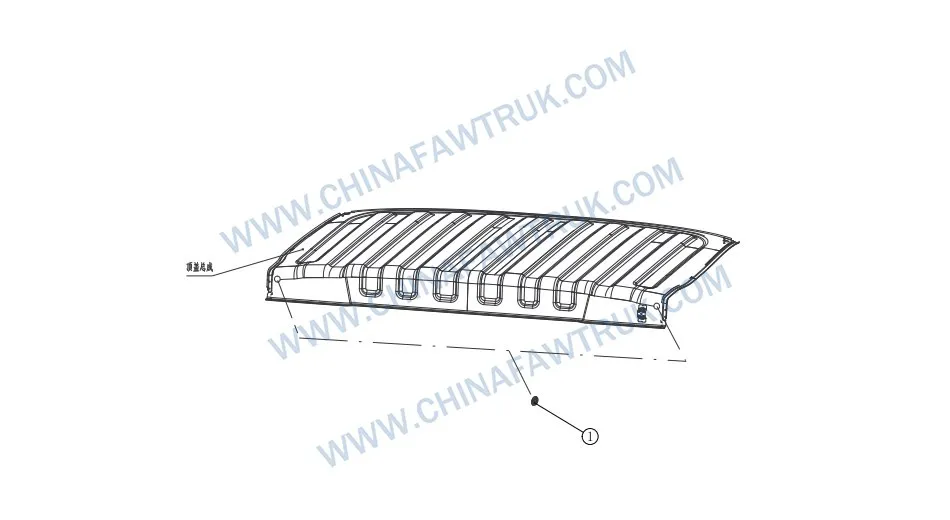

FAW Russian Roof Cover Blockage: Essential 2-Piece Sealing Kit for Flawless Arctic Weatherproofing

The FAW Russian Roof Cover Blockage assembly is a critical weather-sealing solution designed for the CA3250P66K24L1TE5Z dump truck. Situated at the apex of the cabin, this system seals manufacturing apertures that would otherwise be vulnerable to water ingress. In the Russian Federation, where snow loads on the roof can persist for months, the integrity of these plugs is the primary defense against interior leaks, ensuring a dry and protected operating environment.

FAW Russian Roof Cover Blockage

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5704161-A86 | Plug – Roof Cover | 2 |

Defense Against Overhead Water Ingress

The primary function of the FAW Russian Roof Cover Blockage is to maintain the watertight integrity of the cabin roof. During the manufacturing process of the J6P cab, various holes are stamped into the roof panel to accommodate positioning jigs or optional equipment like roof horns and light bars. For standard dump truck configurations, these unused apertures must be sealed. The Plug – Roof Cover (Part No. 5704161-A86) is specifically engineered to close these vulnerabilities. Unlike vertical wall plugs, roof plugs must withstand standing water. In the Russian spring thaw, melting snow can pool on the roof, exerting hydrostatic pressure on the seals.

A failure in the FAW Russian Roof Cover Blockage system leads to immediate and damaging consequences. Water entering through the roof will soak into the headliner insulation, causing sagging and unsightly water stains. More critically, gravity directs this water downward onto the overhead console, which houses sensitive electronics such as the tachograph, radio, and interior lighting controls. By effectively sealing these two critical points, the FAW Russian Roof Cover Blockage prevents expensive electrical short circuits and preserves the hygiene of the cabin interior.

The design of the Plug – Roof Cover incorporates a wide flange that overlaps the hole edge significantly. This overlap creates a primary seal surface. The FAW Russian Roof Cover Blockage logic dictates that the seal must be maintained even if the roof panel flexes under the weight of heavy snow or during chassis torsion on rough roads. The plug acts as a structural cap, maintaining the continuity of the roof skin and preventing wind noise from whistling through open holes at highway speeds.

Material Resilience in Arctic Conditions

The material selection for the FAW Russian Roof Cover Blockage is driven by the extreme thermal cycles of the Russian environment. The roof of a truck is subjected to the most severe temperature fluctuations of any body panel. In summer, direct solar radiation can heat the metal to over 60°C, while winter nights can drop to -50°C. The Plug – Roof Cover is molded from a high-performance UV-stabilized polymer or EPDM rubber blend that resists thermal degradation. Standard plastics would crack or shrink under these conditions, breaking the seal.

The “A86” specification in the part number suggests a material formulation optimized for cold-weather ductility. Even at cryogenic temperatures, the FAW Russian Roof Cover Blockage components must remain flexible enough to maintain an interference fit with the steel roof panel. If the plug were to become rigid, the differential contraction between the plastic plug and the steel roof would open a gap, allowing meltwater to seep in. The FAW Russian Roof Cover Blockage ensures a dynamic seal that moves with the materials.

Furthermore, the material must be resistant to chemical attack. The roof is often exposed to industrial fallout, tree sap, and potentially acidic rain. The FAW Russian Roof Cover Blockage plugs are non-reactive, ensuring they do not degrade or chalk over time. This chemical stability is vital for maintaining the aesthetic appearance of the vehicle, as faded or crumbling plugs would detract from the professional look of the fleet and indicate poor maintenance standards.

Installation Logic and Retention

Secure retention is a key engineering feature of the FAW Russian Roof Cover Blockage. The roof of a dump truck moving at speed experiences significant aerodynamic lift and vibration. A loosely fitted plug could be sucked out by the vacuum created over the cab or shaken loose by the road surface. The Plug – Roof Cover utilizes a “snap-lock” barb design or an expandable body that anchors it firmly from the underside of the sheet metal. This positive retention ensures that the FAW Russian Roof Cover Blockage remains in place for the life of the vehicle.

Installation of the FAW Russian Roof Cover Blockage often requires a specific sealant application for 100% reliability. While the plug has mechanical seals, factory protocols may call for a bead of butyl or silicone sealant around the flange during assembly. This redundancy ensures that even if the mechanical fit relaxes slightly over years of service, the chemical bond prevents water tracking. Fleet technicians replacing these plugs should always clean the mating surface thoroughly to ensure the FAW Russian Roof Cover Blockage adheres correctly.

The profile of the Plug – Roof Cover is designed to be low-profile and aerodynamic. A protruding plug would create wind noise and disrupt the airflow over the roof. The FAW Russian Roof Cover Blockage sits flush with the roof contours, contributing to the overall sleekness of the cab. This flush fit also prevents the plug from being snagged by low-hanging branches or automated wash brushes, protecting the integrity of the seal in various operating scenarios.

Inspection and Replacement Strategy

Despite their simple appearance, the components of the FAW Russian Roof Cover Blockage require periodic inspection. Because they are located on the roof, they are often “out of sight, out of mind” until a leak occurs. Fleet managers should include a roof inspection as part of the annual service, especially before the winter season. Checking the condition of the two Plug – Roof Cover units can prevent costly interior damage. Signs of UV damage, such as cracking or discoloration, indicate that the FAW Russian Roof Cover Blockage is nearing the end of its service life.

If a leak is suspected, a water test can verify the integrity of the FAW Russian Roof Cover Blockage. By spraying water over the roof plugs while an observer checks the interior headliner for moisture, technicians can isolate the failure. It is important to differentiate between a leaking plug and a leaking windshield seal or marker light. Accurate diagnosis prevents unnecessary replacement of the FAW Russian Roof Cover Blockage when the fault lies elsewhere.

When replacement is necessary, using the genuine Plug – Roof Cover is essential. Generic rubber grommets often lack the UV stability and the precise diameter required for the FAW roof stamping. An ill-fitting plug is a guaranteed leak. The genuine FAW Russian Roof Cover Blockage part is manufactured to the exact tolerances of the cab, ensuring a snap-fit that restores the factory weatherproofing standard immediately upon installation.

Conclusion: Small Plugs, Big Protection

The FAW Russian Roof Cover Blockage assembly proves that size does not equal importance. These two modest plugs stand as the final barrier between the harsh arctic elements and the comfortable interior of the cab. By sealing the roof against standing water and ice, they protect the vehicle’s electrical systems and interior trim from water damage.

For fleet operators, maintaining the FAW Russian Roof Cover Blockage is a simple yet vital maintenance task. Ensuring these seals are intact prevents the gradual degradation of the cabin environment. By treating these components with the same attention as mechanical parts, operators ensure that their fleet remains dry, safe, and professional, ready to tackle the challenges of the Russian heavy transport sector.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.