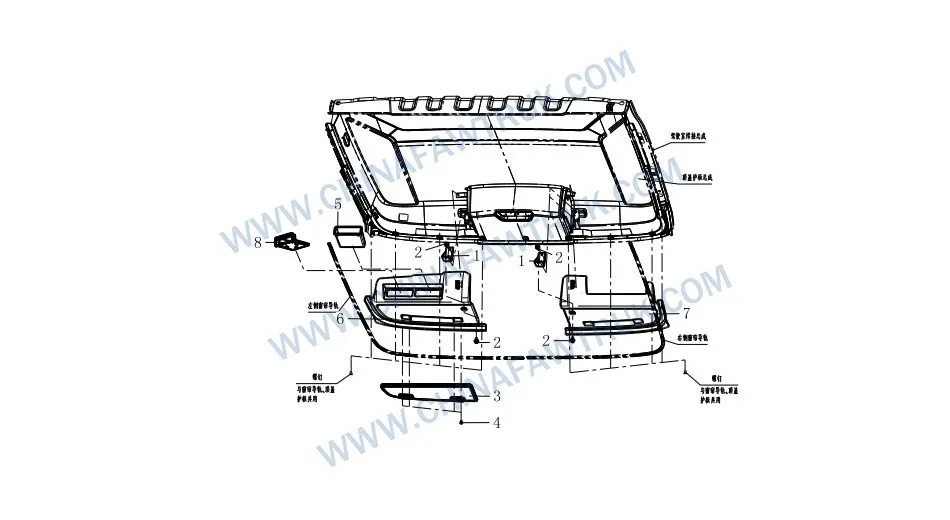

FAW Russian Elevated Container Assembly: The Superior 8-Component Solution for Flawless Cabin Organization

The FAW Russian Elevated Container Assembly is a specialized overhead storage system designed for the CA3250P66K24L1TE5Z dump truck. Situated above the windscreen, this assembly maximizes cabin utility by utilizing vertical space for essential gear. In the cluttered environment of long-haul mining operations, the FAW Russian Elevated Container Assembly provides a secure, vibration-resistant repository for documents and tools, ensuring a clutter-free and safe workspace for the driver.

FAW Russian Elevated Container Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5315030-B35 | Lower Fixing Bracket Assembly – Elevated Container (See 5315031-B35) | 2 |

| 2 | Q2360620F6 | Cross Recessed Pan Head Screw and Washer Assembly | 6 |

| 3 | 8204015-A01 | Left Front Sunvisor Assembly | 1 |

| 4 | CQ2714819F6 | Cross Recessed Pan Head Tapping Screw | 4 |

| 5 | 5315072AA02 | Storage Bucket – Elevated Container | 1 |

| 6 | 5315015-B35 | Left Elevated Container Assembly | 1 |

| 7 | 5315020-B35 | Right Elevated Container Assembly (See 5315022-B35) | 1 |

| 8 | 5315080-A02 | Fixing Bracket Assembly – Reading Lamp Controller (See 5315081-A02) | 1 |

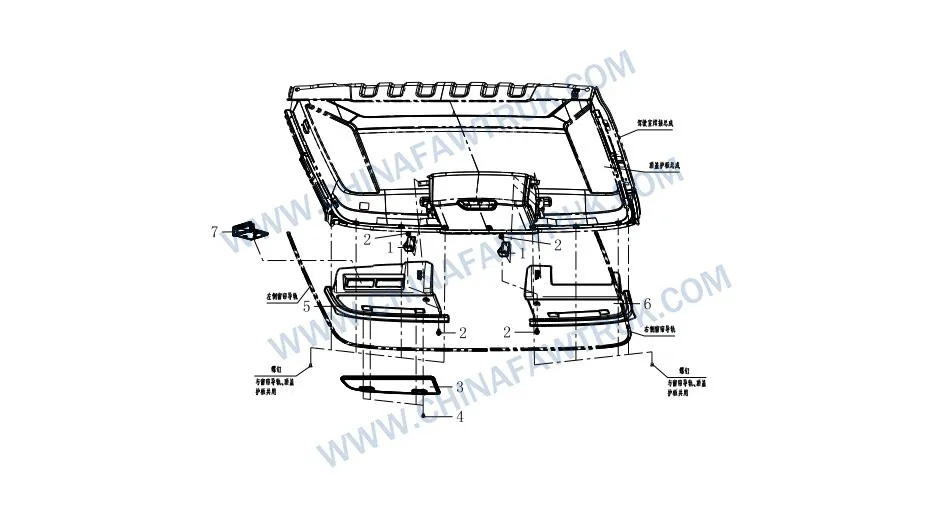

FAW Russian Elevated Box Assembly 2 (for Dashcam Installation)

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5315030-B35 | Lower Fixing Bracket Assembly – Elevated Container (See 5315031-B35) | 2 |

| 2 | Q2360620F6 | Cross Recessed Pan Head Screw and Washer Assembly | 6 |

| 3 | 8204015-A01 | Left Front Sunvisor Assembly | 1 |

| 4 | CQ2714819F6 | Cross Recessed Pan Head Tapping Screw | 4 |

| 5 | 5315015-B35 | Left Elevated Container Assembly | 1 |

| 6 | 5315020-B35 | Right Elevated Container Assembly (See 5315022-B35) | 1 |

| 7 | 5315080-A02 | Fixing Bracket Assembly – Reading Lamp Controller (See 5315081-A02) | 1 |

Modular Storage Architecture and Integration

The FAW Russian Elevated Container Assembly is constructed from high-grade, injection-molded polymers designed to withstand the wide temperature variance of the Russian climate. The core of the system comprises the Left Elevated Container Assembly (Part No. 5315015-B35) and the Right Elevated Container Assembly (Part No. 5315020-B35). These large-volume bins are shaped to contour perfectly against the curvature of the J6P roofline, maximizing internal volume without encroaching on driver headroom. The material is impact-modified to prevent shattering in extreme cold, ensuring that the FAW Russian Elevated Container Assembly remains a durable repository for heavy items like logbooks, flashlights, and winter gloves.

Structural rigidity is provided by the Lower Fixing Bracket Assembly – Elevated Container (Part No. 5315030-B35). These steel brackets anchor the polymer bins to the cab’s metal framework. In the high-vibration environment of a dump truck, a purely plastic mounting point would fatigue and fail. The steel brackets of the FAW Russian Elevated Container Assembly absorb the dynamic loads generated when the truck traverses rough terrain, preventing the overhead console from rattling or detaching. This robust mounting logic is essential for maintaining a quiet and safe cabin environment.

Central to the assembly is the Storage Bucket – Elevated Container (Part No. 5315072AA02). This open-faced compartment provides quick access to frequently used items. Its positioning between the left and right closed bins creates a balanced aesthetic and functional layout. The FAW Russian Elevated Container Assembly design ensures that all storage compartments are within easy reach of the driver, adhering to ergonomic standards that reduce distraction and improve operational efficiency.

Electronics Integration and Utility

The FAW Russian Elevated Container Assembly is not merely for passive storage; it serves as a mounting platform for cabin electronics. The Fixing Bracket Assembly – Reading Lamp Controller (Part No. 5315080-A02) is integrated into the structure to house the overhead lighting controls and potentially the tachograph unit. This bracket ensures that sensitive electronic modules are isolated from roof vibration. The FAW Russian Elevated Container Assembly routes wiring harnesses through dedicated channels behind the bins, protecting them from chafing and ensuring a clean, wire-free cabin appearance.

Also integrated into this overhead system is the Left Front Sunvisor Assembly (Part No. 8204015-A01). While primarily a visibility aid, the sunvisor’s mounting points are often shared with or concealed by the container assembly. This integration streamlines the interior design. In the Arctic summer, where low-angle sun glare is a persistent hazard, the stable mounting of the sunvisor within the FAW Russian Elevated Container Assembly ensures it can be deployed smoothly without wobbling, providing reliable eye protection for the driver.

The material finish of the FAW Russian Elevated Container Assembly is textured to match the dashboard and door trims, creating a cohesive interior design. This surface texture is also scratch-resistant and easy to clean, a practical consideration for mining trucks where dust and grease are omnipresent. The integration of lighting, storage, and sun protection into a single FAW Russian Elevated Container Assembly unit demonstrates the efficiency of the FAW J6P cabin layout.

Fastening Strategy and Durability

The security of the FAW Russian Elevated Container Assembly relies on a specific set of fasteners designed for plastic-to-metal interfaces. The primary structural screws are the Cross Recessed Pan Head Screw and Washer Assembly (Part No. Q2360620F6). These fasteners feature a wide integrated washer that distributes clamping pressure, preventing the screw head from pulling through the plastic mounting tabs of the container bins. The “F6” coating ensures corrosion resistance, preventing rust stains from forming on the overhead console due to condensation.

For lighter components or blind fixings, the assembly utilizes Cross Recessed Pan Head Tapping Screw (Part No. CQ2714819F6). These self-tapping screws bite securely into the plastic bosses or sheet metal clips, providing a rattle-free hold. The FAW Russian Elevated Container Assembly engineering specifies the torque values for these screws carefully; over-tightening can strip the plastic threads, while under-tightening leads to annoying squeaks and rattles as the cab flexes.

The fastening logic also considers ease of service. The exposed screw heads allow for quick removal of the FAW Russian Elevated Container Assembly panels to access the wiper motor mechanism or roof wiring located behind the headliner. This serviceability is crucial for minimizing downtime during electrical repairs. The use of standard cross-recess drive types means that no special tools are required to dismantle the overhead console in the field.

Maintenance and Component Care

Maintenance of the FAW Russian Elevated Container Assembly is primarily focused on inspection and cleaning. Fleet operators should check the security of the mounting screws during regular service intervals. A loose overhead bin can become a safety hazard in the event of a sudden stop. If any of the Lower Fixing Bracket Assembly units are bent or cracked from overloading the bins, they must be replaced immediately to restore structural integrity to the FAW Russian Elevated Container Assembly.

The plastic components, such as the Left Elevated Container Assembly and Right Elevated Container Assembly, should be cleaned with mild interior cleaners. Harsh solvents can damage the surface finish or make the plastic brittle. Drivers should be advised not to overload the bins with heavy metal tools that could slide around and crack the plastic housing. Using the FAW Russian Elevated Container Assembly within its design limits ensures longevity.

In the event of damage, individual components of the FAW Russian Elevated Container Assembly can be replaced. The modular design allows for the Storage Bucket or a single side bin to be swapped out without replacing the entire system. Genuine FAW parts ensure that the replacement panels match the color and texture of the existing interior, preserving the vehicle’s resale value and professional appearance.

Conclusion: Organizational Excellence

The FAW Russian Elevated Container Assembly is a key element of the J6P’s driver-centric design. Comprising 8 distinct components, it transforms the overhead space into a functional, organized storage area. Its robust construction and integration with vehicle electronics make it indispensable for long-haul operations.

For fleet managers, the state of the FAW Russian Elevated Container Assembly reflects the overall care given to the vehicle. A functional, rattle-free overhead console improves driver satisfaction and safety. By maintaining this assembly with genuine parts and proper care, operators ensure that their drivers have the organized environment they need to perform efficiently in the challenging conditions of the Russian transport sector.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.