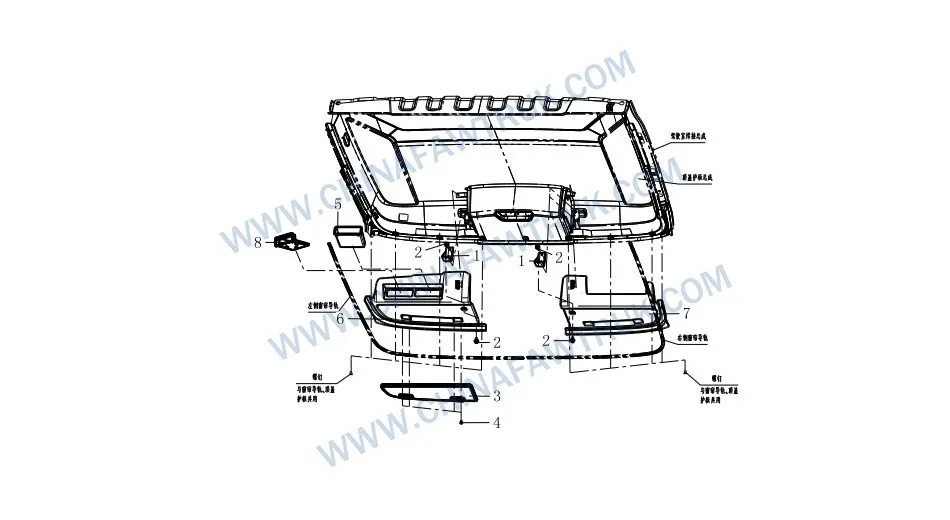

Сборка контейнеров FAW в России: Превосходное 8-компонентное решение для безупречной организации салона

The Сборка контейнеров FAW в России — специализированная система верхнего хранения, разработанная для самосвала CA3250P66K24L1TE5Z.. Расположен над лобовым стеклом, эта сборка максимизирует полезность кабины за счет использования вертикального пространства для основного оборудования.. В запутанной среде дальних горнодобывающих работ, а Сборка контейнеров FAW в России обеспечивает безопасную, виброустойчивое хранилище для документов и инструментов, обеспечение беспрепятственного и безопасного рабочего места для водителя.

Сборка контейнеров FAW в России

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 | 5315030-Б35 | Нижний крепежный кронштейн в сборе – Повышенный контейнер (См. 5315031-B35.) | 2 |

| 2 | Q2360620F6 | Винт с крестообразным углублением и шайбой в сборе | 6 |

| 3 | 8204015-А01 | Левый передний солнцезащитный козырек в сборе | 1 |

| 4 | CQ2714819F6 | Поперечный постукивающий поддон | 4 |

| 5 | 5315072АА02 | Ведро для хранения – Повышенный контейнер | 1 |

| 6 | 5315015-Б35 | Левый приподнятый контейнер в сборе | 1 |

| 7 | 5315020-Б35 | Правый приподнятый контейнер в сборе (См. 5315022-B35.) | 1 |

| 8 | 5315080-А02 | Крепежный кронштейн в сборе – Контроллер лампы для чтения (См. 5315081-A02.) | 1 |

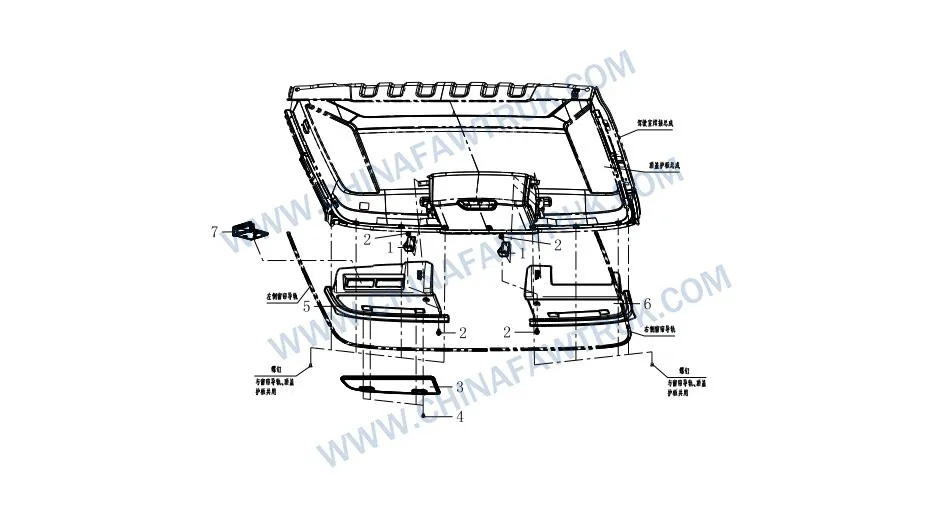

FAW Русский повышенный фургон в сборе 2 (для установки видеорегистратора)

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 | 5315030-Б35 | Нижний крепежный кронштейн в сборе – Повышенный контейнер (См. 5315031-B35.) | 2 |

| 2 | Q2360620F6 | Винт с крестообразным углублением и шайбой в сборе | 6 |

| 3 | 8204015-А01 | Левый передний солнцезащитный козырек в сборе | 1 |

| 4 | CQ2714819F6 | Поперечный постукивающий поддон | 4 |

| 5 | 5315015-Б35 | Левый приподнятый контейнер в сборе | 1 |

| 6 | 5315020-Б35 | Правый приподнятый контейнер в сборе (См. 5315022-B35.) | 1 |

| 7 | 5315080-А02 | Крепежный кронштейн в сборе – Контроллер лампы для чтения (См. 5315081-A02.) | 1 |

Модульная архитектура хранения данных и интеграция

The Сборка контейнеров FAW в России построен из высококачественного, injection-molded polymers designed to withstand the wide temperature variance of the Russian climate. The core of the system comprises the Левый приподнятый контейнер в сборе (Часть №. 5315015-Б35) и Правый приподнятый контейнер в сборе (Часть №. 5315020-Б35). These large-volume bins are shaped to contour perfectly against the curvature of the J6P roofline, maximizing internal volume without encroaching on driver headroom. The material is impact-modified to prevent shattering in extreme cold, обеспечение того, чтобы Сборка контейнеров FAW в России remains a durable repository for heavy items like logbooks, flashlights, and winter gloves.

Structural rigidity is provided by the Нижний крепежный кронштейн в сборе – Повышенный контейнер (Часть №. 5315030-Б35). These steel brackets anchor the polymer bins to the cab’s metal framework. В условиях повышенной вибрации самосвала, a purely plastic mounting point would fatigue and fail. The steel brackets of the Сборка контейнеров FAW в России absorb the dynamic loads generated when the truck traverses rough terrain, preventing the overhead console from rattling or detaching. Эта надежная схема монтажа необходима для поддержания тихой и безопасной среды в салоне..

Центральное место в собрании занимает Ведро для хранения – Повышенный контейнер (Часть №. 5315072АА02). Открытое отделение обеспечивает быстрый доступ к часто используемым предметам.. Его расположение между левым и правым закрытыми контейнерами создает сбалансированную эстетическую и функциональную компоновку.. The Сборка контейнеров FAW в России конструкция гарантирует, что все отсеки для хранения вещей находятся в пределах легкой досягаемости водителя, соблюдение эргономических стандартов, которые уменьшают отвлечение внимания и повышают эффективность работы.

Интеграция электроники и утилиты

The Сборка контейнеров FAW в России предназначен не только для пассивного хранения; служит монтажной платформой для электроники салона. The Крепежный кронштейн в сборе – Контроллер лампы для чтения (Часть №. 5315080-А02) интегрирован в конструкцию для размещения органов управления верхним освещением и, возможно, блока тахографа.. Этот кронштейн обеспечивает изоляцию чувствительных электронных модулей от вибрации крыши.. The Сборка контейнеров FAW в России прокладывает жгуты проводов через специальные каналы за бункерами, защищая их от натирания и обеспечивая чистоту, внешний вид беспроводной кабины.

В эту накладную систему также интегрирована Левый передний солнцезащитный козырек в сборе (Часть №. 8204015-А01). Хотя в первую очередь это средство наглядности, Точки крепления солнцезащитного козырька часто совпадают с контейнером или скрыты им.. Эта интеграция упрощает дизайн интерьера.. Арктическим летом, где солнечные блики под низким углом представляют постоянную опасность, стабильное крепление солнцезащитного козырька внутри Сборка контейнеров FAW в России гарантирует плавное развертывание без раскачивания, обеспечивающая надежную защиту глаз водителя.

Материал отделки Сборка контейнеров FAW в России текстурирован в тон приборной панели и обшивке дверей., создание целостного дизайна интерьера. Эта текстура поверхности также устойчива к царапинам и легко чистится., a practical consideration for mining trucks where dust and grease are omnipresent. The integration of lighting, хранилище, and sun protection into a single Сборка контейнеров FAW в России unit demonstrates the efficiency of the FAW J6P cabin layout.

Fastening Strategy and Durability

Безопасность Сборка контейнеров FAW в России relies on a specific set of fasteners designed for plastic-to-metal interfaces. The primary structural screws are the Винт с крестообразным углублением и шайбой в сборе (Часть №. Q2360620F6). These fasteners feature a wide integrated washer that distributes clamping pressure, preventing the screw head from pulling through the plastic mounting tabs of the container bins. The “F6” coating ensures corrosion resistance, preventing rust stains from forming on the overhead console due to condensation.

For lighter components or blind fixings, the assembly utilizes Поперечный постукивающий поддон (Часть №. CQ2714819F6). These self-tapping screws bite securely into the plastic bosses or sheet metal clips, providing a rattle-free hold. The Сборка контейнеров FAW в России инженерные разработки тщательно определяют значения крутящего момента для этих винтов.; чрезмерная затяжка может сорвать пластиковую резьбу, в то время как недостаточная затяжка приводит к раздражающим скрипам и дребезжанию при прогибании кабины.

Логика крепления также учитывает простоту обслуживания.. Открытые головки винтов позволяют быстро снять Сборка контейнеров FAW в России панели для доступа к механизму электродвигателя стеклоочистителей или проводке крыши, расположенной за обшивкой потолка. Удобство обслуживания имеет решающее значение для минимизации простоев во время ремонта электрооборудования.. Использование стандартных приводов с поперечными пазами означает, что для демонтажа потолочной консоли в полевых условиях не требуются специальные инструменты..

Техническое обслуживание и уход за компонентами

Техническое обслуживание Сборка контейнеров FAW в России в первую очередь ориентирован на осмотр и очистку. Операторы автопарка должны проверять надежность крепежных винтов во время регулярных интервалов технического обслуживания.. Незакрепленный верхний багажный отсек может стать угрозой безопасности в случае внезапной остановки.. Если какой-либо из Нижний крепежный кронштейн в сборе блоки погнуты или треснуты из-за перегрузки контейнеров, их необходимо немедленно заменить, чтобы восстановить структурную целостность Сборка контейнеров FAW в России.

Пластиковые компоненты, такие как Левый приподнятый контейнер в сборе и Правый приподнятый контейнер в сборе, следует мыть мягкими чистящими средствами для салона. Агрессивные растворители могут повредить отделку поверхности или сделать пластик хрупким.. Водителям следует рекомендовать не перегружать контейнеры тяжелыми металлическими инструментами, которые могут соскользнуть и повредить пластиковый корпус.. Используя Сборка контейнеров FAW в России в пределах проектных ограничений обеспечивает долговечность.

В случае повреждения, отдельные компоненты Сборка контейнеров FAW в России можно заменить. Модульная конструкция позволяет Ведро для хранения или один боковой контейнер, который можно заменить без замены всей системы. Оригинальные детали FAW гарантируют, что заменяемые панели будут соответствовать цвету и текстуре существующего салона., сохранение перепродажной стоимости и профессионального внешнего вида автомобиля.

Заключение: Организационное совершенство

The Сборка контейнеров FAW в России является ключевым элементом ориентированного на водителя дизайна J6P.. Состоит из 8 отдельные компоненты, превращает верхнее пространство в функциональное, организованное складское помещение. Его прочная конструкция и интеграция с автомобильной электроникой делают его незаменимым для дальних перевозок..

Для менеджеров флота, состояние Сборка контейнеров FAW в России отражает общий уход за автомобилем. Функциональный, Верхняя консоль без дребезжания повышает удовлетворенность и безопасность водителя. При поддержании этого узла с использованием оригинальных деталей и надлежащем уходе., операторы обеспечивают своим водителям организованную среду, необходимую для эффективной работы в сложных условиях российского транспортного сектора.

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..