FAW Russian Rear Combination Lamp Logic: Unveiling 4 Critical Nodes for Uncompromising Arctic Visibility

The FAW Russian Rear Combination Lamp logic assembly is the primary signaling system for the rear of the CA3250P66K24L1TE5Z dump truck. In the low-visibility conditions of the Russian Arctic, where blowing snow and fog can obscure a vehicle in seconds, this assembly provides the essential “stop,” “turn,” and “position” indications to following traffic. Engineered with high-intensity optics and robust weather sealing, the FAW Russian Rear Combination Lamp ensures that the truck remains visible and communicative, preventing rear-end collisions in the harshest environments.

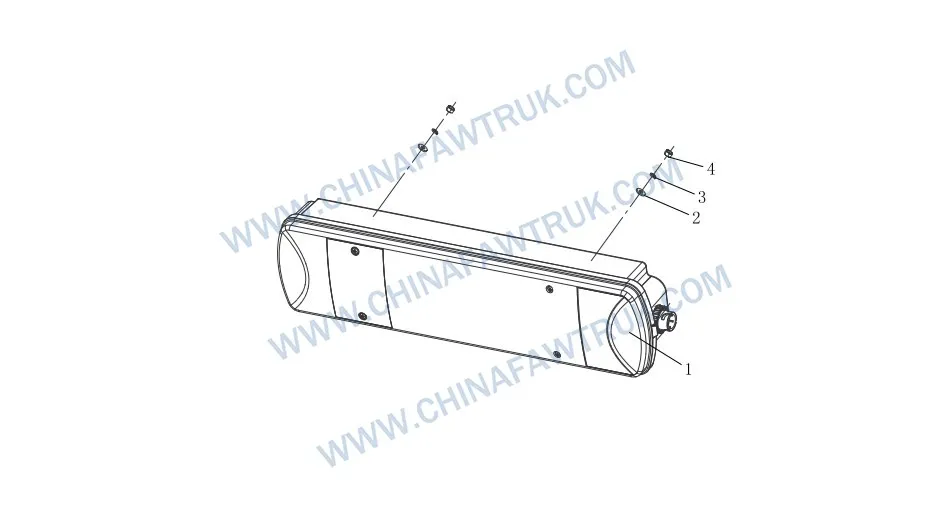

FAW Russian Rear Combination Lamp

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3716015-91W-C00 | Left Rear Combination Lamp Assembly | 1 |

| 1 | 3716020-91W-C00 | Right Rear Combination Lamp Assembly | 1 |

| 2 | Q40110 | Washer | 4 |

| 3 | Q40310 | Spring Washer | 4 |

| 4 | CQ34010 | Hexagon Nut | 4 |

Optical Performance and Safety Logic

The FAW Russian Rear Combination Lamp is designed to cut through the visual noise of a mining site. It features multi-chamber optics that separate the brake, turn, and reverse functions. The Left Rear Combination Lamp Assembly (Part No. 3716015-91W-C00) typically includes a dedicated rear fog lamp, a mandatory requirement for Russian regulations. This high-intensity red light provides a piercing beacon in whiteout conditions, allowing following drivers to gauge distance accurately.

The lenses of the FAW Russian Rear Combination Lamp are molded from impact-resistant polycarbonate. Unlike acrylic, which can shatter at -40°C, polycarbonate retains its ductility, shrugging off impacts from gravel flung by the rear tires. The optical design incorporates retro-reflective elements directly into the lens surface, providing passive visibility even when the truck is parked and powered down. This redundancy is a critical safety layer for the FAW Russian Rear Combination Lamp system.

Illumination is provided by heavy-duty bulbs or LED arrays, depending on the specific trim. In the context of the FAW Russian Rear Combination Lamp, vibration resistance is the primary concern. The bulb sockets are suspension-mounted within the housing to dampen the high-frequency shocks transmitted through the chassis. This “floating” design significantly extends bulb life, reducing the frequency of maintenance interventions in the field.

Sealing and Environmental Protection

The rear of a dump truck is a hostile environment, constantly bombarded by mud, water, and de-icing chemicals. The FAW Russian Rear Combination Lamp housing is engineered to be hermetically sealed against these threats. The interface between the lens and the base is bonded with a permanent adhesive sealant, preventing moisture ingress that could corrode the reflector or fog the lens.

Electrical connections to the Right Rear Combination Lamp Assembly (Part No. 3716020-91W-C00) are made via a rear-mounted, weather-pack connector. This connector features multiple silicone ribs that create a watertight seal around the pin terminals. Additionally, the wiring entry point is often potted or grommeted to prevent water from wicking down the wire strands into the lamp interior. For the FAW Russian Rear Combination Lamp, maintaining dry internals is essential for preventing short circuits and bulb failures.

To manage internal pressure changes caused by the heat of the bulbs and the freezing exterior air, the FAW Russian Rear Combination Lamp incorporates a gore-tex breather patch. This allows air to expand and contract without drawing in moisture or dust. This pressure equalization prevents seal stress and ensures that the lamp remains watertight through thousands of thermal cycles.

Mounting and Serviceability

The FAW Russian Rear Combination Lamp is secured to the chassis bracket using a robust stud-and-nut system. The assembly includes integrated mounting studs that pass through the bracket, secured by a Hexagon Nut (Part No. CQ34010), a Spring Washer (Part No. Q40310), and a flat Washer (Part No. Q40110). This three-part fastening system ensures that the lamp remains tight under vibration while allowing for slight adjustability during installation.

The position of the FAW Russian Rear Combination Lamp is often recessed within a steel guard or the rear bumper structure to protect it from impact during dumping operations. However, this can make access difficult. The design of the mounting studs allows for installation and removal from the rear, simplifying replacement without requiring the disassembly of the protective guarding.

Corrosion of the mounting hardware is a common issue in salty environments. The studs and nuts used for the FAW Russian Rear Combination Lamp are plated with a high-grade zinc-nickel coating to resist rust. Maintenance involves checking the torque of these nuts periodically. A loose lamp will vibrate excessively, leading to filament breakage and potential housing cracks. Keeping the FAW Russian Rear Combination Lamp securely mounted is the first step in ensuring long-term reliability.

Electrical Integration and Diagnostics

The FAW Russian Rear Combination Lamp integrates with the truck’s central body controller. It shares a common ground but utilizes separate power feeds for each function (stop, tail, turn, reverse, fog). This separation allows for precise diagnostics; if one function fails, it does not affect the others. The wiring harness leading to the lamp is routed inside the chassis rails to protect it from abrasion and ice buildup.

Diagnosing issues with the FAW Russian Rear Combination Lamp is straightforward. Most failures are due to burnt-out bulbs or corroded sockets. However, if multiple functions fail simultaneously, the issue is likely a bad ground connection at the chassis or a loose main connector. Technicians should inspect the connector pins for green copper oxide corrosion, a sure sign of water ingress.

For LED versions of the FAW Russian Rear Combination Lamp, the entire unit is sealed and non-serviceable. While the initial cost is higher, the lifespan is significantly longer. Fleet operators upgrading to LED units must ensure that the flasher relay is compatible with the lower current draw to prevent “hyper-flashing.” Regardless of the technology, the FAW Russian Rear Combination Lamp remains a vital safety component that demands regular inspection and immediate repair.

Conclusion: Visibility is Safety

The FAW Russian Rear Combination Lamp logic assembly is the final line of defense against rear-end collisions. With its rugged construction, advanced optics, and secure mounting, it ensures that the truck’s intentions are clearly communicated to other road users. The 4 primary components listed form a robust system capable of surviving the brutal conditions of the Russian Arctic.

For fleet owners, maintaining the FAW Russian Rear Combination Lamp is a legal and safety imperative. Using genuine parts ensures correct fitment and optical compliance. By keeping these lamps clean, functional, and securely mounted, operators protect their investment and the lives of those sharing the road.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.