FAW مجموعة المصابيح الخلفية الروسية: كشف النقاب 4 العقد الحاسمة لرؤية القطب الشمالي لا هوادة فيها

ال FAW مجموعة المصابيح الخلفية الروسية التجميع المنطقي هو نظام الإشارات الأساسي للجزء الخلفي من الشاحنة القلابة CA3250P66K24L1TE5Z. في ظروف الرؤية المنخفضة في القطب الشمالي الروسي, حيث يمكن أن يؤدي هبوب الثلوج والضباب إلى حجب السيارة في ثوانٍ, يوفر هذا التجميع الأساسيات “قف,” “دور,” و “موضع” مؤشرات لمتابعة حركة المرور. تم تصميمه باستخدام بصريات عالية الكثافة وختم قوي للطقس, ال FAW مجموعة المصابيح الخلفية الروسية يضمن بقاء الشاحنة مرئية ومتواصلة, منع الاصطدامات الخلفية في أقسى البيئات.

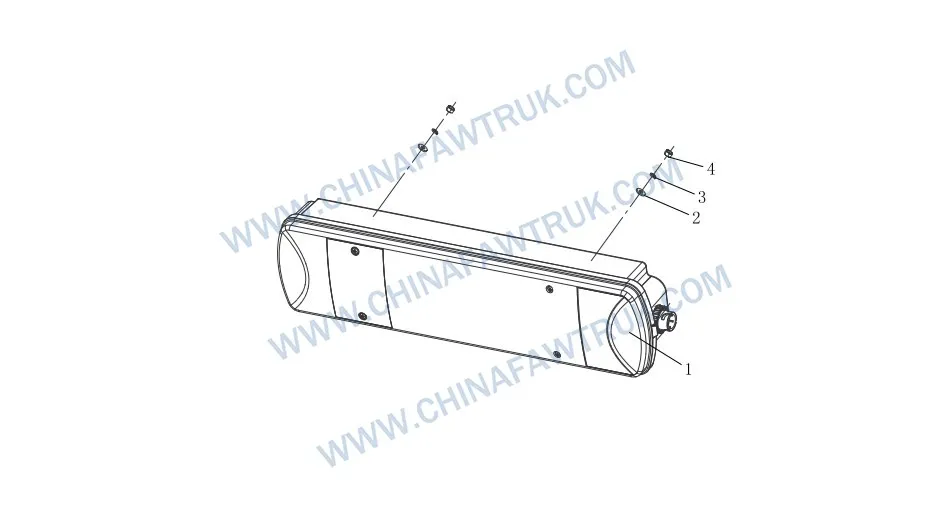

FAW مجموعة المصابيح الخلفية الروسية

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 | 3716015-91W-C00 | مجموعة المصابيح الخلفية اليسرى | 1 |

| 1 | 3716020-91W-C00 | مجموعة المصابيح الخلفية اليمنى | 1 |

| 2 | س40110 | غسالة | 4 |

| 3 | س40310 | غسالة الربيع | 4 |

| 4 | CQ34010 | الجوز السداسي | 4 |

الأداء البصري ومنطق السلامة

ال FAW مجموعة المصابيح الخلفية الروسية تم تصميمه لقطع الضوضاء المرئية لموقع التعدين. يتميز بصريات متعددة الغرف تفصل الفرامل, دور, والوظائف العكسية. ال مجموعة المصابيح الخلفية اليسرى (الجزء لا. 3716015-91W-C00) يتضمن عادةً مصباح ضباب خلفي مخصصًا, شرط إلزامي للوائح الروسية. يوفر هذا الضوء الأحمر عالي الكثافة منارة خارقة في ظروف التبييض, السماح للسائقين التاليين بقياس المسافة بدقة.

العدسات FAW مجموعة المصابيح الخلفية الروسية مصنوعة من مادة البولي كربونات المقاومة للصدمات. على عكس الاكريليك, والتي يمكن أن تتكسر عند -40 درجة مئوية, يحتفظ البولي كربونات بالليونة, متجاهلاً تأثيرات الحصى التي تقذفها الإطارات الخلفية. يتضمن التصميم البصري عناصر عاكسة للضوء مباشرة على سطح العدسة, توفير رؤية سلبية حتى عندما تكون الشاحنة متوقفة ومتوقفة عن العمل. يعد هذا التكرار بمثابة طبقة أمان مهمة لـ FAW مجموعة المصابيح الخلفية الروسية نظام.

يتم توفير الإضاءة بواسطة المصابيح الثقيلة أو صفائف LED, اعتمادا على تقليم معين. في سياق FAW مجموعة المصابيح الخلفية الروسية, مقاومة الاهتزاز هي الشاغل الرئيسي. يتم تثبيت مآخذ اللمبة داخل الهيكل لتخفيف الصدمات عالية التردد المنقولة عبر الهيكل. هذا “عائم” يعمل التصميم على إطالة عمر المصباح بشكل كبير, تقليل وتيرة تدخلات الصيانة في الميدان.

الختم وحماية البيئة

يمثل الجزء الخلفي من الشاحنة القلابة بيئة معادية, يقصفها الطين باستمرار, ماء, والمواد الكيميائية لإزالة الجليد. ال FAW مجموعة المصابيح الخلفية الروسية تم تصميم السكن ليكون مغلقًا بإحكام ضد هذه التهديدات. يتم ربط الواجهة بين العدسة والقاعدة بمادة لاصقة دائمة, منع دخول الرطوبة التي قد تؤدي إلى تآكل العاكس أو ضباب العدسة.

التوصيلات الكهربائية لل مجموعة المصابيح الخلفية اليمنى (الجزء لا. 3716020-91W-C00) مصنوعة عبر مثبتة في الخلف, موصل حزمة الطقس. يتميز هذا الموصل بأضلاع سيليكون متعددة تعمل على إنشاء ختم مانع للماء حول أطراف الدبوس. بالإضافة إلى ذلك, غالبًا ما يتم وضع نقطة دخول الأسلاك في وعاء أو جروميت لمنع الماء من فتل خيوط الأسلاك إلى الجزء الداخلي للمصباح. ل FAW مجموعة المصابيح الخلفية الروسية, يعد الحفاظ على الأجزاء الداخلية الجافة أمرًا ضروريًا لمنع حدوث دوائر قصيرة وفشل المصابيح.

لإدارة تغيرات الضغط الداخلي الناجمة عن حرارة المصابيح والهواء الخارجي المتجمد, ال FAW مجموعة المصابيح الخلفية الروسية يتضمن رقعة استراحة جور تكس. وهذا يسمح للهواء بالتمدد والانكماش دون سحب الرطوبة أو الغبار. يمنع معادلة الضغط هذا إجهاد الختم ويضمن بقاء المصباح مانعًا للماء خلال آلاف الدورات الحرارية.

التركيب وإمكانية الخدمة

ال FAW مجموعة المصابيح الخلفية الروسية يتم تثبيته على دعامة الهيكل باستخدام نظام مسمار وجوز قوي. يتضمن التجميع مسامير تثبيت مدمجة تمر عبر الحامل, مؤمن بواسطة أ الجوز السداسي (الجزء لا. CQ34010), أ غسالة الربيع (الجزء لا. س40310), وشقة غسالة (الجزء لا. س40110). يضمن نظام التثبيت المكون من ثلاثة أجزاء بقاء المصباح مشدودًا تحت الاهتزاز مع السماح بتعديل بسيط أثناء التثبيت.

موقف ال FAW مجموعة المصابيح الخلفية الروسية غالبًا ما يتم تثبيته داخل واقي فولاذي أو هيكل المصد الخلفي لحمايته من الصدمات أثناء عمليات الإغراق. لكن, وهذا يمكن أن يجعل الوصول صعبًا. يسمح تصميم مسامير التثبيت بالتركيب والإزالة من الخلف, تبسيط الاستبدال دون الحاجة إلى تفكيك الحماية الواقية.

يعد تآكل أجهزة التثبيت مشكلة شائعة في البيئات المالحة. الأزرار والمكسرات المستخدمة في FAW مجموعة المصابيح الخلفية الروسية وهي مطلية بطبقة من الزنك والنيكل عالي الجودة لمقاومة الصدأ. تتضمن الصيانة فحص عزم دوران هذه الصواميل بشكل دوري. سوف يهتز المصباح السائب بشكل مفرط, مما يؤدي إلى كسر الخيوط والشقوق المحتملة في السكن. الحفاظ على FAW مجموعة المصابيح الخلفية الروسية التثبيت الآمن هو الخطوة الأولى لضمان الموثوقية على المدى الطويل.

التكامل الكهربائي والتشخيص

ال FAW مجموعة المصابيح الخلفية الروسية يتكامل مع وحدة التحكم المركزية في الجسم للشاحنة. إنها تشترك في أرضية مشتركة ولكنها تستخدم مغذيات طاقة منفصلة لكل وظيفة (قف, ذيل, دور, يعكس, ضباب). يسمح هذا الفصل بالتشخيص الدقيق; إذا فشلت وظيفة واحدة, ولا يؤثر على الآخرين. يتم توجيه مجموعة الأسلاك المؤدية إلى المصباح داخل قضبان الهيكل لحمايتها من التآكل وتراكم الجليد.

تشخيص المشاكل مع FAW مجموعة المصابيح الخلفية الروسية هو واضح ومباشر. ترجع معظم حالات الفشل إلى المصابيح المحترقة أو المقابس المتآكلة. لكن, إذا فشلت وظائف متعددة في وقت واحد, من المحتمل أن تكون المشكلة عبارة عن اتصال أرضي سيئ في الهيكل أو موصل رئيسي مفكك. يجب على الفنيين فحص دبابيس الموصل بحثًا عن تآكل أكسيد النحاس الأخضر, علامة أكيدة على دخول الماء.

لإصدارات LED من FAW مجموعة المصابيح الخلفية الروسية, الوحدة بأكملها مغلقة وغير قابلة للخدمة. في حين أن التكلفة الأولية أعلى, العمر الافتراضي أطول بكثير. يجب على مشغلي الأسطول الذين يقومون بالترقية إلى وحدات LED التأكد من أن مرحل المتعري متوافق مع سحب التيار المنخفض لمنع ذلك “فرط الوميض.” بغض النظر عن التكنولوجيا, ال FAW مجموعة المصابيح الخلفية الروسية يبقى عنصرًا حيويًا للسلامة يتطلب فحصًا منتظمًا وإصلاحًا فوريًا.

خاتمة: الرؤية هي السلامة

ال FAW مجموعة المصابيح الخلفية الروسية التجميع المنطقي هو خط الدفاع الأخير ضد الاصطدامات الخلفية. مع بنائه الوعرة, البصريات المتقدمة, وتركيب آمن, فهو يضمن توصيل نوايا الشاحنة بوضوح لمستخدمي الطريق الآخرين. ال 4 تشكل المكونات الأساسية المذكورة نظامًا قويًا قادرًا على النجاة من الظروف القاسية في القطب الشمالي الروسي.

لأصحاب الأسطول, الحفاظ على FAW مجموعة المصابيح الخلفية الروسية هو ضرورة قانونية وأمنية. يضمن استخدام قطع الغيار الأصلية التركيب الصحيح والتوافق البصري. من خلال الحفاظ على نظافة هذه المصابيح, وظيفية, ومثبتة بشكل آمن, يحمي المشغلون استثماراتهم وحياة أولئك الذين يتشاركون الطريق.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.