FAW Russian Side Turn Signal Assembly: Unlocking 14 Vital Components for 360-Degree Visibility

The FAW Russian Side Turn Signal assembly is a critical element of the passive safety architecture for the CA3250P66K24L1TE5Z dump truck. In the congested and low-visibility environments of urban construction sites or remote Arctic mines, these lateral indicators provide essential communication of driver intent to adjacent traffic and pedestrians. Engineered to withstand side impacts and harsh weather, the FAW Russian Side Turn Signal ensures that the vehicle’s turning actions are clearly telegraphed, reducing the risk of side-swipe accidents in blinding snow or heavy dust.

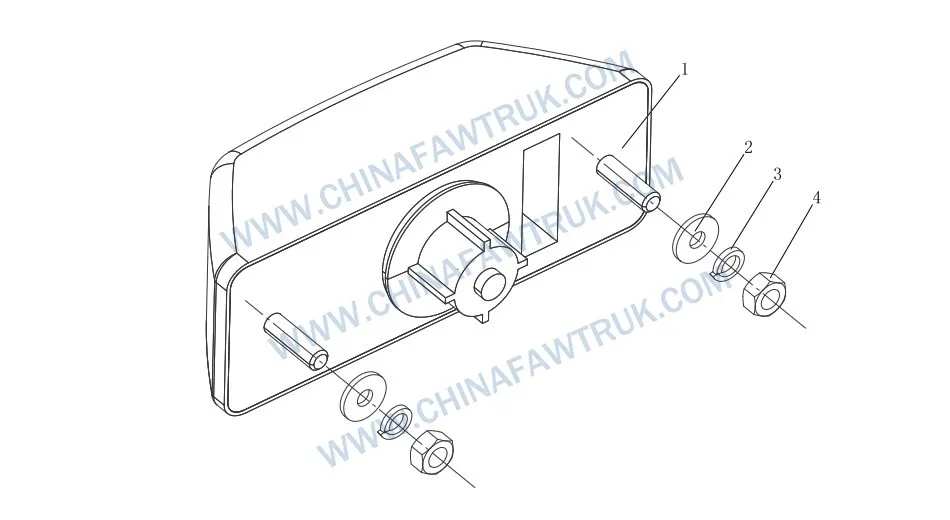

FAW Russian Side Turn Signal

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3726030A109 | Side Turn Signal Lamp Assembly | 2 |

| 2 | Q40106 | Washer | 4 |

| 3 | Q40306 | Spring Washer | 4 |

| 4 | CQ34006 | Hexagon Nut | 4 |

Strategic Placement and Optical Design

The FAW Russian Side Turn Signal is strategically positioned on the fender or door panel to cover the “blind spot” inherent in large commercial vehicles. While the front and rear indicators manage head-on and following traffic, the FAW Russian Side Turn Signal is specifically aimed at cyclists, pedestrians, and smaller vehicles that may be alongside the truck during a turn. In the Russian market, where lane discipline can be variable due to snow-covered markings, this lateral visibility is a legal and safety imperative.

The optical lens of the Side Turn Signal Lamp Assembly (Part No. 3726030A109) features a prismatic design that scatters light in a wide arc, typically exceeding 60 degrees. This ensures that the flashing amber signal is visible even to a driver sitting low in a passenger car right next to the dump truck’s massive tires. The lens material is a high-impact acrylic or polycarbonate, resistant to the crazing and cracking caused by extreme cold and UV radiation at high altitudes.

Illumination within the FAW Russian Side Turn Signal is provided by a vibration-resistant bulb or LED cluster. Given the location on the side of the cab or fender, this lamp is subject to significant shock as the suspension cycles. The bulb socket is often isolation-mounted within the housing to dampen these forces, preventing filament fracture. This design consideration ensures that the FAW Russian Side Turn Signal remains operational on washboard gravel roads where standard bulbs would fail rapidly.

Sealing Against the Elements

The mounting location of the FAW Russian Side Turn Signal exposes it to direct wheel spray, which in Russia often contains a corrosive mix of salt, sand, and chemical de-icers. To combat this, the assembly features a hermetically sealed housing. The lens is permanently bonded to the base using ultrasonic welding or industrial adhesives, creating a monolithic structure that is impervious to water ingress. This sealing is vital to prevent internal corrosion of the reflector, which would degrade the light output of the FAW Russian Side Turn Signal over time.

The electrical interface is another critical vulnerability. The wiring harness enters the back of the FAW Russian Side Turn Signal through a rubber grommet or a potted connector. This seal must remain flexible at -50°C to prevent cracking, which would allow brine to wick into the lamp. The connector terminals are typically plated to resist oxidation, ensuring a low-resistance connection that maintains full brightness even after years of exposure to humidity and salt.

Furthermore, the FAW Russian Side Turn Signal is designed with a low profile to minimize the risk of impact damage from brush or narrow gate openings. The streamlined shape also reduces wind noise and prevents the buildup of ice and snow on the leading edge of the lens. This aerodynamic consideration helps keep the lens clear, ensuring that the FAW Russian Side Turn Signal remains effective without requiring constant manual cleaning by the driver.

Securement and Mounting Logic

Installing the FAW Russian Side Turn Signal requires a secure fastening method that does not damage the vehicle’s body panels. The assembly utilizes integrated studs on the back of the housing, which pass through the fender or door skin. Securement is achieved using the Hexagon Nut (Part No. CQ34006), tightened against the interior surface. This blind-mount design leaves no exposed screw heads on the exterior, reducing the risk of vandalism and improving the vehicle’s aesthetic.

To prevent the nuts from loosening under vibration, the installation includes a Spring Washer (Part No. Q40306). This washer maintains tension on the threaded stud, compensating for any thermal contraction of the plastic housing in extreme cold. A flat Washer (Part No. Q40106) is used to distribute the clamping force over a wider area of the sheet metal, preventing the nut from pulling through or distorting the thin panel.

The mounting studs of the FAW Russian Side Turn Signal are often made of brass or coated steel to prevent seizing. In the corrosive environment of a wheel well, a rusted nut can make replacement impossible without destroying the lamp. The use of corrosion-resistant fasteners ensures that the FAW Russian Side Turn Signal can be easily serviced or replaced in the field using standard hand tools, minimizing downtime for minor repairs.

Maintenance and Replacement

Maintenance of the FAW Russian Side Turn Signal is generally limited to bulb replacement (if serviceable) and cleaning. However, given the low cost and sealed nature of modern units, full replacement is often the standard procedure for a failed lamp. Fleet mechanics should regularly check the operation of these lights during walk-around inspections, as a non-functioning side repeater is a common reason for regulatory fines and safety citations.

When replacing a FAW Russian Side Turn Signal, it is crucial to clean the mounting surface on the body panel. Dirt or rust trapped under the gasket can prevent a proper seal, leading to water ingress into the body cavity. Additionally, applying a small amount of dielectric grease to the electrical connector protects the contacts from oxidation.

For fleets operating in severe off-road conditions, keeping spare Side Turn Signal Lamp Assembly units in stock is recommended. These protruding lights are prone to damage from brush, rocks, and tight maneuvering. Quick replacement ensures that the truck maintains its full safety envelope. By using genuine FAW parts, operators ensure perfect fitment and color matching, maintaining the professional appearance and safety compliance of the vehicle.

Conclusion: Small Light, Big Safety

The FAW Russian Side Turn Signal assembly is a vital component of the J6P’s comprehensive lighting system. Comprising just 14 parts in total (2 lamps and 12 fasteners), it provides the lateral visibility necessary to prevent accidents during turning maneuvers. Its rugged construction and thoughtful design ensure reliable operation in the most challenging environments.

For fleet operators, the FAW Russian Side Turn Signal is a reminder that safety is built into the details. Ensuring these lamps are functional, clean, and securely mounted is a fundamental part of responsible vehicle ownership. By maintaining these critical indicators, fleets protect their drivers and the public, ensuring safe and efficient operations across the Russian landscape.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.