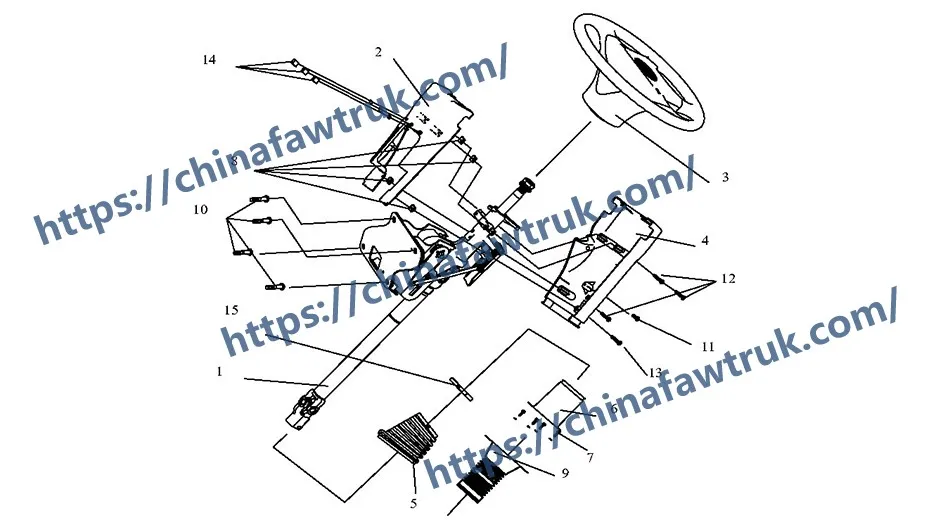

This is a complete technical guide to the FAW J6P Steering Mechanism for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes 17 serviceable component types that form the complete in-cab steering assembly, from the steering wheel to the column covers and mounting brackets.

The FAW J6P Steering Mechanism is the driver’s primary interface for vehicle control. It is not just the steering wheel; it is the entire assembly that translates the driver’s rotational input into a mechanical force that actuates the steering gear. For a heavy-duty dump truck, this system must be robust, reliable, and ergonomically sound. It is designed to be vibration-resistant, providing a solid, confident feel. This deconstruction will analyze the key serviceable parts of the in-cab FAW J6P Steering Mechanism, including the driver interface, the structural column bracket, and the various seals and covers that protect the assembly. A fully functional FAW J6P Steering Mechanism is non-negotiable for operator safety and precise vehicle maneuvering in demanding off-road environments.

This component is the primary tactile part of the FAW J6P Steering Mechanism. It is the assembly that the driver physically interacts with to control the vehicle.

1. Component: ‘Steering wheel & horn button assy’ (3402010-10W) – Qty 1

This (Comp 3) is the complete steering wheel assembly. The Ergonomic Logic is critical here; the wheel is designed with a large diameter to provide the necessary leverage for a heavy-duty truck, and it is made from a durable, high-grip polyurethane material. This is the main input device for the entire FAW J6P Steering Mechanism.

This assembly also includes the integrated ‘Horn Button’. This is a primary safety feature, allowing the driver to provide an audible warning without removing their hands from the wheel. The complete assembly is splined and secured to the top of the steering column with a single large nut. This entire FAW J6P Steering Mechanism interface is designed for long life and reliability.

This is the structural backbone of the FAW J6P Steering Mechanism. It is the assembly that mounts the steering wheel to the vehicle’s cab and transfers the rotational force to the intermediate shaft.

1. Component: ‘Steering column bracket & flexible shaft assy’ (3403010-60W) – Qty 1

This (Comp 1) is the single most important structural part of the in-cab FAW J6P Steering Mechanism. The Bracket Logic involves a heavy-gauge, stamped-steel bracket that bolts securely to the vehicle’s firewall or dashboard support. This rigid mounting is essential to prevent any ‘play’ or flexing in the steering, which would give the driver a vague and unsafe feeling.

The ‘Flexible Shaft’ aspect is also critical. This part of the assembly (often a ‘rag joint’) connects the solid steering column shaft to the intermediate shaft. Its Vibration Damping Logic is to absorb and isolate the driver’s hands from the harsh vibrations and shocks coming from the engine and the road. This small amount of flex is essential for driver comfort and reduces fatigue. The entire FAW J6P Steering Mechanism relies on this part for both rigidity and isolation.

This group of components provides the aesthetic finish and, more importantly, the environmental seals for the FAW J6P Steering Mechanism.

1. Component: Column Covers (3403061-10W, 3403062-10W, 3403051-50A)

This (Comp 2, 4, 6) is the set of plastic covers (‘护套’) that enclose the steering column. This includes the ‘Front/rear steering column cover’ (Comp 2) and the ‘Steering column lower cover’ (Comp 6). Their function is twofold: first, they provide a finished, aesthetic look inside the cab. Second, they act as a safety guard, preventing the driver’s clothing or other items from becoming entangled in the rotating column.

2. Component: ‘Dust cover’ (3403049-10W, 3403067-50A, 3003064-50A)

This (Comp 5, 9, 16) is the set of flexible rubber seals. The Environmental Sealing Logic is vital for driver comfort and safety. These covers (‘防尘罩’, ‘挡尘板’) are typically located on the firewall where the steering column passes through. They create an airtight and watertight seal, preventing noise, heat, dust, and engine fumes from entering the cab. A failure here would make the vehicle extremely loud and unpleasant to drive. These seals are a key, non-negotiable part of the FAW J6P Steering Mechanism.

This group includes the various bolts, screws, nuts, and clips used to assemble the FAW J6P Steering Mechanism and secure it to the vehicle.

1. Component: Main Bracket Hardware (CQ1420625F6B, NO15448)

This (Comp 7, 8) is the high-strength hardware for mounting the ‘Steering column bracket’ (Comp 1). The ‘Combination bolts’ (Comp 7) and ‘Spring plate nuts’ (Comp 8) are designed to be vibration-resistant. The Fastener Logic ensures that the main support bracket for the FAW J6P Steering Mechanism cannot work itself loose over time.

2. Component: Cover & Trim Hardware (CQ2714245, CQ2714213, Q40105, 3403166-50A)

This (Comp 12, 13, 14) is the hardware for the plastic covers. This includes ‘Cross recessed pan head self-tapping screws’ (Comp 12, 13) with their ‘Washers’ (Q40105), and ‘Clips’ (Comp 14). These are designed to secure the plastic covers firmly to prevent rattles and squeaks inside the cab, ensuring a quiet FAW J6P Steering Mechanism.

3. Component: ‘Clamp’ (3403063-10W) & ‘Hose clamp’ (CQ676120B)

This (Comp 15, 17) is a set of clamps. The ‘Worm drive hose clamp’ (Comp 17) is likely used to secure the main ‘Steering column dust cover’ (Comp 9) to the column or firewall, creating that airtight seal. Every piece of hardware is critical to the safe, reliable, and quiet operation of the FAW J6P Steering Mechanism.

The following table provides the complete, detailed breakdown of all 17 component types in the FAW J6P Steering Mechanism assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for any service of the FAW J6P Steering Mechanism.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3403010-60W | Steering column bracket & flexible shaft assy | 1 |

| 2 | 3403061-10W | Front/rear steering column cover | 1 |

| 3 | 3402010-10W | Steering wheel & horn button assy | 1 |

| 4 | 3403062-10W | Rear steering column cover | 1 |

| 5 | 3403049-10W | Dust cover | 1 |

| 6 | 3403051-50A | Steering column lower cover | 1 |

| 7 | CQ1420625F6B | Combination bolt | 4 |

| 8 | NO15448 | Spring plate nut | 4 |

| 9 | 3403067-50A | Steering column dust cover | 1 |

| 10 | CQ1421235 | Combination bolt | 4 |

| 11 | Q2360616 | Cross recessed pan head screw assy | 1 |

| 12 | CQ2714245 / Q40105 | Cross recessed pan head self-tapping screw & Washer | 3 |

| 13 | CQ2714213 / Q40105 | Cross recessed pan head self-tapping screw & Washer | 1 |

| 14 | 3403166-50A | Clip – front steering column cover | 3 |

| 15 | 3403063-10W | Clamp | 1 |

| 16 | 3003064-50A | Dust baffle plate | 1 |

| 17 | CQ676120B | Worm drive hose clamp Type B | 1 |

The specifications for the FAW J6P Steering Mechanism are defined by its role as the primary driver interface for steering control. A properly functioning FAW J6P Steering Mechanism is critical for vehicle safety.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Steering Mechanism |

| Primary Logic | In-cab driver steering control interface |

| Driver Interface | ‘Steering wheel & horn button assy’ (3402010-10W) |

| Main Structural Component | ‘Steering column bracket & flexible shaft assy’ (3403010-60W) |

| Key Feature | Includes flexible shaft for vibration damping |

| Environmental Sealing | ‘Steering column dust cover’ (3403067-50A) |

| Total Component Types | 17 |

| Associated System | Cab Interior / Steering System. The FAW J6P Steering Mechanism is the start of the chain. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.