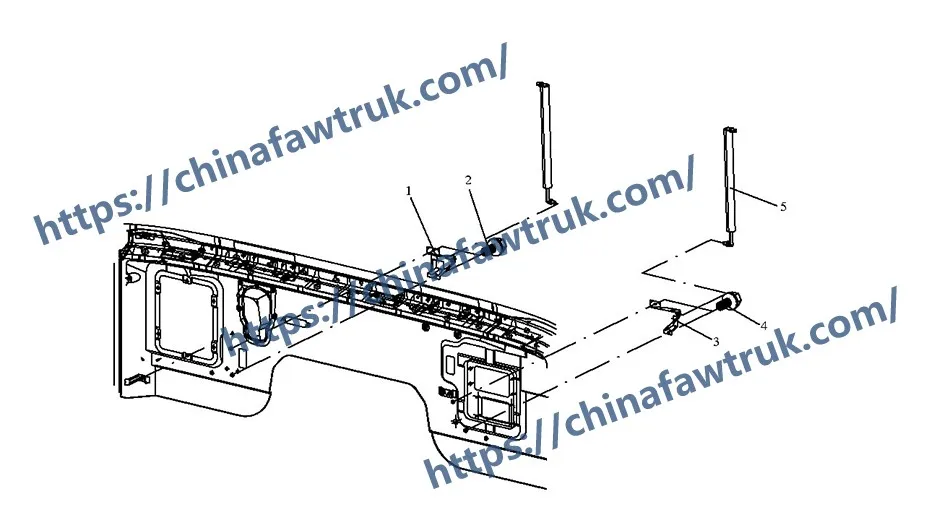

This is a comprehensive technical guide to the FAW J6P Gas Spring assembly (front enclosure) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 5 serviceable component types, detailing the main pneumatic strut, the heavy-duty mounting brackets, and the specific hardware.

The FAW J6P Gas Spring is a critical component for both safety and convenience. Its primary function is to provide the lifting force required to open the heavy front enclosure panel (grille), and more importantly, to hold that panel securely in the open position. This allows for safe, hands-free access to daily service points like the engine oil dipstick, coolant reservoir, and washer fluid.

This deconstruction will analyze the key serviceable components of the FAW J6P Gas Spring system. This includes the main gas-charged cylinder (the spring itself), the robust steel mounting brackets that anchor it to the cab and panel, and the high-tensile bolts that secure those brackets. A failing FAW J6P Gas Spring is a significant safety hazard, as it can result in the heavy front panel collapsing on an operator. A properly functioning FAW J6P Gas Spring is essential for efficient daily maintenance.

This is the functional heart of the entire FAW J6P Gas Spring system. This single component provides both the lifting force and the controlled motion required for the heavy front panel.

1. Component: ‘Gas spring assy – front enclosure’ (5302410-A01) – Qty 2

This (Comp 5) is the gas-charged strut. The Pneumatic Lift Logic is that this is a sealed cylinder containing high-pressure nitrogen gas, separated from a small amount of hydraulic oil by a piston. The gas provides the “spring” force, constantly trying to extend the rod. This force is precisely calculated to be slightly more than the weight of the panel, allowing it to lift with minimal effort.

The Hydraulic Damping Logic is the second crucial function. The piston inside the FAW J6P Gas Spring has a small orifice (hole). As the rod moves, it must push the hydraulic oil through this hole. This restriction provides damping, preventing the heavy front panel from flying open or slamming shut. This controlled, smooth motion is the signature of a healthy FAW J6P Gas Spring.

The most common failure mode for the FAW J6P Gas Spring is a seal failure. Over time, the main rod seal (which keeps the high-pressure gas inside) wears out. Gas slowly leaks, and the strut loses its ability to hold the panel up. This is a critical safety failure, as the panel can then fall unexpectedly. This component is not serviceable and must be replaced as a complete assembly.

This group of components provides the structural mounting points that anchor the FAW J6P Gas Spring to the vehicle. These brackets must withstand the full, constant force of the gas struts.

1. Component: ‘Left lower bracket assy – gas spring’ (5302445-A01) – Qty 1

This (Comp 1) is the dedicated mounting bracket for the left-hand side. The Load-Bearing Logic requires this to be a heavy-duty, fabricated steel component. It is bolted directly to the vehicle’s rigid chassis or cab structure. It provides the “fixed” or lower anchor point for the FAW J6P Gas Spring.

2. Component: ‘Right lower bracket assy – gas spring’ (5302450-A01) – Qty 1

This (Comp 3) is the mirrored counterpart for the right-hand side. The use of distinct left and right brackets shows that the mounting points are asymmetrical, designed to fit a specific location on the chassis.

The Articulation Logic is critical. Gas springs do not mount rigidly; they must be able to pivot as the panel opens in an arc. These brackets (Comp 1 and 3) typically feature a ball stud (a small metal ball on a threaded post). The end of the FAW J6P Gas Spring (Comp 5) has an integrated socket that “snaps” onto this ball, allowing it to pivot freely. A worn or corroded ball stud on this FAW J6P Gas Spring bracket will cause the strut to bind, leading to a bent rod and complete system failure.

This final group includes the high-strength hardware used to secure the anchor brackets (Core 2) of the FAW J6P Gas Spring system to the vehicle frame.

1. Component: ‘Combination bolt’ (CQ1460616F6) – Qty 4 (Total)

This (Comp 2 and 4) is the primary mounting bolt. The Vibration Resistance Logic is critical. These four bolts (two for each bracket) are “combination” bolts, meaning they have a pre-attached (captive) washer. This design ensures the clamping load is distributed over a wider area of the bracket, and more importantly, that the washer is never accidentally omitted during service.

These bolts are high-tensile and must be torqued to a specific factory setting. If these bolts become loose, the entire FAW J6P Gas Spring bracket (Comp 1 or 3) will flex. This flexing will quickly fatigue the metal of the bracket or the bolt itself, leading to a catastrophic failure where the entire strut assembly detaches from the vehicle. This is why a simple bolt is a critical, non-negotiable part of the FAW J6P Gas Spring safety system.

The following table provides the complete, detailed breakdown of all 5 component types in the FAW J6P Gas Spring assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the FAW J6P Gas Spring.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5302445-A01 | Left lower bracket assy – gas spring | 1 |

| 2 | CQ1460616F6 | Combination bolt | 2 |

| 3 | 5302450-A01 | Right lower bracket assy – gas spring | 1 |

| 4 | CQ1460616F6 | Combination bolt | 2 |

| 5 | 5302410-A01 | Gas spring assy – front enclosure | 2 |

The specifications for the FAW J6P Gas Spring are defined by its function as a high-pressure pneumatic strut, providing the lift and damping force for the heavy front enclosure panel.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Gas Spring (Front Enclosure) |

| Primary Logic | Pneumatic lift-assist and hydraulic damping |

| Core Component P/N | 5302410-A01 (Gas spring assy) |

| Anchor Brackets | ‘Left/Right lower bracket assy’ (5302445/450-A01) |

| Mounting Hardware | ‘Combination bolt’ (CQ1460616F6) |

| Total Component Types | 5 |

| Associated System | Cab Exterior / Service Access. The FAW J6P Gas Spring is the core mechanism. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.