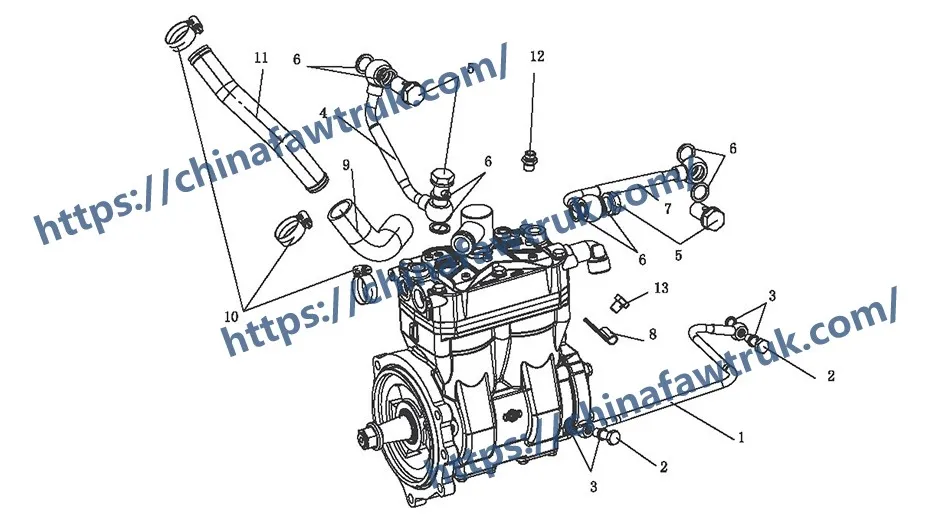

Welcome to the definitive guide for the FAW Air Compressor2 ancillary systems, the second part of our detailed breakdown for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This document focuses on the critical external plumbing and support components.

While our first guide examined the main compressor unit, this FAW Air Compressor2 guide analyzes the vital “life support” systems that allow it to function: the high-pressure oil inlet pipe, the liquid coolant circulation pipes (inlet and return), and the clean air intake piping.

This information is essential for service technicians, fleet managers, and parts specialists. A failure in the FAW Air Compressor2 ancillary plumbing—such as a split coolant hose, a leaking oil line, or a cracked air intake boot—will lead to the rapid and catastrophic failure of the main compressor unit, compromising the vehicle’s entire pneumatic and braking system.

The first set of components in the FAW Air Compressor2 parts list defines its lubrication system. The ‘Engine Oil Inlet Pipe Assembly’ (3509050-53D) is the main artery, designed to tap into the engine’s main oil gallery and deliver a continuous supply of high-pressure, filtered engine oil directly to the compressor’s internal crankshaft and bearings.

This oil feed is not optional; without it, the high-speed reciprocating components inside the compressor would generate immense friction and seize within minutes. This pipe is pre-bent (as indicated by “as-per-sample”) to perfectly fit the engine.

This pipe is sealed using two ‘Banjo Bolts’ (3509053-29D) and four ‘Copper Gaskets 10X16’ (Q/WC3403-1994-3). A banjo bolt is a hollow, perforated bolt that allows fluid (in this case, oil) to pass through it. The soft copper gaskets are “crush washers,” one placed on either side of the pipe’s “banjo” fitting, to create a high-pressure, high-temperature seal. The 2:4 ratio (2 bolts, 4 gaskets) is a critical detail for technicians, as replacing these gaskets is mandatory during any service to prevent catastrophic oil leaks from the FAW Air Compressor2 assembly.

The process of compressing air to over 120 PSI generates an extreme amount of heat. To prevent the compressor from overheating, overheating the oil, and passing burnt oil (coke) into the air system, the FAW Air Compressor2 system is fully liquid-cooled. This is accomplished by plumbing it directly into the engine’s main cooling system, and this module details all the parts required for that circuit.

This is a complete, continuous-flow circuit. First, the ‘Air Compressor Inlet Water Pipe Assembly’ (3509030-53D) takes relatively cool, pressurized coolant from the engine block and delivers it into the compressor’s water jacket. After the coolant circulates through the compressor, absorbing its waste heat, it exits via the ‘Air Compressor Return Water Pipe Assembly’ (3509020-53D), which carries the now-hot coolant back into the engine’s cooling system to be processed by the water pump and radiator.

Both of these rigid pipes (also marked “as-per-sample”) are critical, pre-formed components. Their integrity is vital for the survival of the main compressor unit. A leak in either pipe or its fittings will quickly starve the compressor of coolant, leading to seizure. The FAW Air Compressor2 system’s reliability is entirely dependent on this cooling loop.

Similar to the oil line, this cooling circuit is sealed with banjo fittings. The parts list calls for four ‘Banjo Bolts M14X1.5’ (Q/XC3451.1-2002) and eight ‘Gaskets 14X20’ (Q/WC3403-94(14X20)). This 4:8 ratio perfectly illustrates the assembly: each of the two pipes (inlet and return) has two connection points (one at the engine, one at the compressor). Each connection point uses one banjo bolt and two gaskets (one on each side of the fitting). These gaskets are essential, single-use items. Failure to replace all eight during service will result in dangerous coolant leaks and potential failure of the FAW Air Compressor2 system.

The compressor must draw in a high volume of air to function. It is absolutely critical that this air is clean and free of abrasive dust or debris. The FAW Air Compressor2 air intake system is designed to draw air from *after* the engine’s main air filter, providing it with air that is just as clean as what enters the engine’s cylinders.

This intake path consists of two main parts. First, the ‘Air Compressor Inlet Pipe’ (3509286-91W) is a rigid pipe, likely metal or hard plastic, that connects to a port on the engine’s main air intake plenum. Second, this rigid pipe is connected to the compressor’s air inlet port via the ‘Air Compressor Inlet Rubber Hose’ (3509284-2000).

This rubber hose is a vital component. It serves as a flexible decoupler, absorbing the intense vibrations of both the main engine and the reciprocating compressor. Without this flexible joint, the rigid pipe would quickly fatigue-crack. To ensure a perfect, airtight seal, three ‘Worm Drive Hose Clamps B-Type’ (CQ67645B) are used. These clamps must be secured tightly. Any leak in this intake path would create a “vacuum leak,” allowing unfiltered, abrasive-filled air to be sucked directly into the compressor, which would rapidly destroy the compressor’s piston, rings, and cylinder wall.

The final components listed in the FAW Air Compressor2 diagram provide physical support and a key point of transition. The ‘Bracket’ (3509032-29D) is a simple but essential part. The long, rigid coolant and oil pipes cannot be left to hang freely, as engine vibration would quickly cause them to crack. This bracket bolts to the engine or compressor and serves as a secure anchor point for the pipes, isolating them from harmful vibrations.

The ‘Transition Connector Assembly (M12-NG6)’ (3515065-91W) is a special adapter fitting. Its designation suggests it converts the compressor’s M12 threaded output port to a different standard, NG6, which is common for high-pressure hydraulic or pneumatic lines. This is the final output fitting of the entire FAW Air Compressor2 system, where the high-pressure compressed air exits the compressor and begins its journey to the air governor and the vehicle’s air tanks.

The following table provides the complete, detailed breakdown of all components identified in the ‘Air Compressor (Two)’ diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3509050-53D | Engine Oil Inlet Pipe Assembly (as-per-sample) | 1 |

| 2 | 3509053-29D | Banjo Bolt | 2 |

| 3 | Q/WC3403-1994-3 | Copper Gasket 10X16 | 4 |

| 4 | 3509020-53D | Air Compressor Return Water Pipe Assembly (as-per-sample) | 1 |

| 5 | Q/XC3451.1-2002(M14X1.5) | Banjo Bolt | 4 |

| 6 | Q/WC3403-94(14X20) | Gasket | 8 |

| 7 | 3509030-53D | Air Compressor Inlet Water Pipe Assembly (as-per-sample) | 1 |

| 8 | 3509032-29D | Bracket | 1 |

| 9 | 3509284-2000 | Air Compressor Inlet Rubber Hose | 1 |

| 10 | CQ67645B | Worm Drive Hose Clamp B-Type | 3 |

| 11 | 3509286-91W | Air Compressor Inlet Pipe | 1 |

| 12 | 3515065-91W | Transition Connector Assembly (M12-NG6) | 1 |

The specifications for the FAW Air Compressor2 ancillary system are defined by its function as the life-support system for the main compressor. All components are heavy-duty and designed for direct engine integration.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | Air Compressor Ancillary Systems (Plumbing & Mounting) |

| System Name | FAW Air Compressor2 |

| Lubrication System | 1x Oil Inlet Pipe (3509050-53D), 2x Banjo Bolts, 4x Copper Gaskets |

| Cooling System | 1x Inlet Water Pipe (3509030-53D), 1x Return Water Pipe (3509020-53D) |

| Cooling Fasteners | 4x Banjo Bolts (M14X1.5), 8x Gaskets (14X20) |

| Air Intake System | 1x Inlet Pipe (3509286-91W), 1x Rubber Hose (3509284-2000), 3x Clamps (CQ67645B) |

| Support System | 1x Bracket (3509032-29D) |

| Output Fitting | 1x Transition Connector Assembly (3515065-91W) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.