Welcome to the comprehensive technical guide for the FAW Air Compressor (Part No. 3509010-91W), a critical safety component on the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is the heart of the vehicle’s pneumatic system.

In a heavy-duty tractor, the air compressor does more than just power accessories; it is the source of stopping power for the air brake system, a key component for the air-ride suspension, and the power behind the air-actuated gearbox components. The reliability of the FAW Air Compressor is, therefore, non-negotiable.

This guide is designed for professional technicians, maintenance managers, and parts specialists. We will deconstruct the entire FAW Air Compressor mounting and drive assembly into its smallest serviceable units, including the main assembly, its drive gear, critical seals, and mounting fasteners.

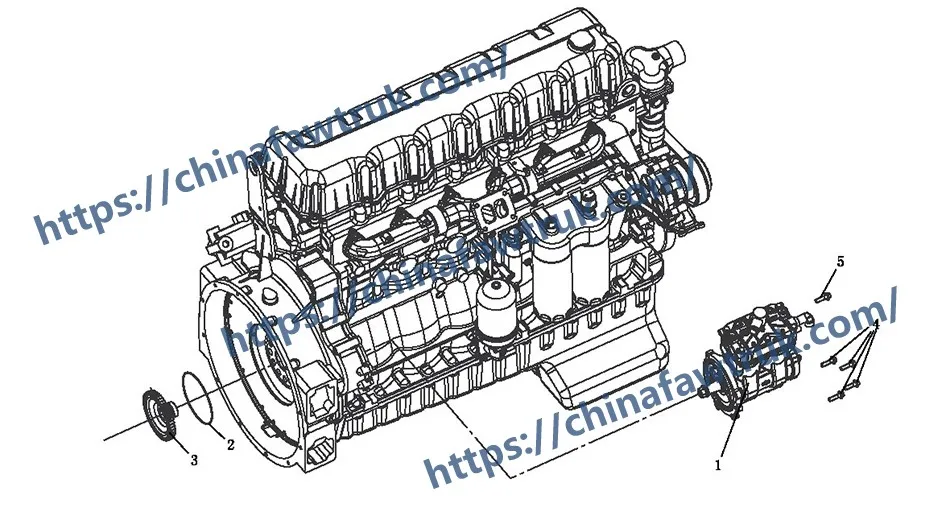

The main component in this diagram is the ‘Air Compressor Assembly’ (3509010-91W). This is the parent unit that is typically replaced as a complete assembly during a major failure. This is not a simple, belt-driven accessory; it is a heavy-duty, engine-integrated pump. On this FAW model, the FAW Air Compressor is a reciprocating piston-type pump, likely a robust single-cylinder or twin-cylinder design, engineered for high-volume, continuous-duty operation.

Its operation is fundamental. It draws in filtered air, compresses it to a high pressure (typically over 120 PSI), and then delivers it to an air governor, which in turn fills the vehicle’s primary and secondary air tanks. This assembly is designed to be both liquid-cooled and pressure-lubricated. This means it has internal passages that connect directly to the engine’s cooling and oil systems, which is why the associated seals are so critical.

The head of the FAW Air Compressor contains a set of reed valves or poppet valves for intake and exhaust, which are precision-engineered to handle the high temperatures and pressures. Over time, carbon buildup or mechanical wear can cause these valves to leak, leading to a drop in efficiency, slow air buildup, or the compressor “passing oil” into the air system. When such a failure is diagnosed, replacing the entire FAW Air Compressor assembly is often the most reliable and time-efficient repair.

Unlike on a passenger car, the FAW Air Compressor is not driven by a rubber belt. The power required to generate that much compressed air is substantial, and the reliability standard is much higher. This assembly is gear-driven, directly from the engine’s internal timing gear train. The ‘Air Compressor Driven Gear’ (1006047-81D) is the key component for this power transfer.

This gear is a heavy-duty, hardened steel component, precisely machined with helical-cut teeth. These helical teeth mesh with a drive gear inside the engine’s timing case, providing a positive, high-torque, slip-proof connection. This gear-driven design is exceptionally reliable and maintenance-free compared to a belt, but it also means its installation is more complex.

This gear is pressed or bolted onto the compressor’s own crankshaft. When installing a new FAW Air Compressor, this gear must be transferred, or a new one installed. The condition of this gear is critical; any chipping or excessive wear on the teeth can introduce metal debris into the engine’s timing case, leading to catastrophic engine failure. It is a vital serviceable component, representing the single point of power input for the entire pneumatic system.

The parts list identifies a single ‘O-ring Seal’ (Q734B15000265). It is impossible to overstate the importance of this one, small component. This seal is the primary interface between the FAW Air Compressor and the engine block. Given that the compressor is liquid-cooled and pressure-lubricated, this O-ring is a multi-function seal of critical importance.

This single o-ring is responsible for sealing multiple passages simultaneously as the compressor is bolted to the engine.

This o-ring is made of a special, high-temperature, oil-resistant material (like Viton) designed to withstand the harsh environment of a diesel engine. It is a “one-time-use” part. Whenever the FAW Air Compressor is removed for any reason, this seal *must* be replaced. Re-using an old, compressed, or heat-hardened o-ring is a guarantee for a leak. This single part, though costing very little, is essential for a reliable repair.

The final components on the list are the fasteners that physically secure the FAW Air Compressor to the engine’s gear case. The list calls for two different part numbers: four units of ‘Hex Flange Bolt, Coarse Rod (Standard Type)’ (Q1841035) and one unit of (Q1841025). This 4+1 pattern is typical for mounting heavy, high-vibration accessories.

The four Q1841035 bolts are likely the main mounting bolts, while the single Q1841025 bolt is likely a different length, perhaps used for a location with a different flange thickness or for attaching a support bracket. These are not standard hardware-store bolts. They are ‘Flange Bolts’, which means the head has an integrated washer. This design distributes the clamping force over a wider area, preventing the bolt head from digging into the aluminum or cast-iron compressor flange and creating a secure, vibration-resistant joint.

These are also ‘Standard Type’ coarse rod bolts, indicating a specific (and likely high) tensile strength (e.g., Class 8.8 or 10.9) designed to handle the constant, hammering vibration of both the diesel engine and the reciprocating compressor. Using the correct, factory-specified bolts and tightening them to the precise torque specification is the only way to ensure the heavy FAW Air Compressor does not vibrate loose or crack its mounting flange.

The following table provides the detailed breakdown of components for the FAW Air Compressor and its mounting, as specified for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3509010-91W | Air Compressor Assembly | 1 |

| 2 | Q734B15000265 | O-ring Seal | 1 |

| 3 | 1006047-81D | Air Compressor Driven Gear | 1 |

| 4 | Q1841035 | Hex Flange Bolt, Coarse Rod (Standard Type) | 4 |

| 5 | Q1841025 | Hex Flange Bolt, Coarse Rod (Standard Type) | 1 |

The specifications for the FAW Air Compressor are defined by its critical role as a safety component. The system is designed for high reliability and direct integration with the engine.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | Air Compressor System |

| Parent Part Number | 3509010-91W (Air Compressor Assembly) |

| Drive Type | Gear-Driven (Part No. 1006047-81D) |

| Lubrication Type | Pressurized (Engine Oil) |

| Cooling Type | Liquid-Cooled (Engine Coolant) |

| Primary Interface Seal | 1x O-ring Seal (Q734B15000265) |

| Mounting Fasteners | 4x Q1841035, 1x Q1841025 (Hex Flange Bolts) |

| Primary Function | Generates compressed air for the vehicle’s air brake, suspension, and auxiliary systems. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.