Bem-vindo ao guia técnico completo para o Compressor de ar FAW (Parte não. 3509010-91C), um componente crítico de segurança no FAW Jiefang CA4251P66K24T1A3E5 6×4 trator semirreboque diesel. Esta montagem é o coração do sistema pneumático do veículo.

Em um trator pesado, o compressor de ar faz mais do que apenas acessórios de energia; é a fonte de energia de parada para o sistema de freio a ar, um componente chave para a suspensão pneumática, e a potência por trás dos componentes da caixa de engrenagens acionadas a ar. A confiabilidade do Compressor de ar FAW é, portanto, inegociável.

Este guia foi desenvolvido para técnicos profissionais, gerentes de manutenção, e especialistas em peças. Vamos desconstruir todo Compressor de ar FAW montagem e montagem do acionamento em suas menores unidades utilizáveis, incluindo a montagem principal, sua engrenagem motriz, selos críticos, e fixadores de montagem.

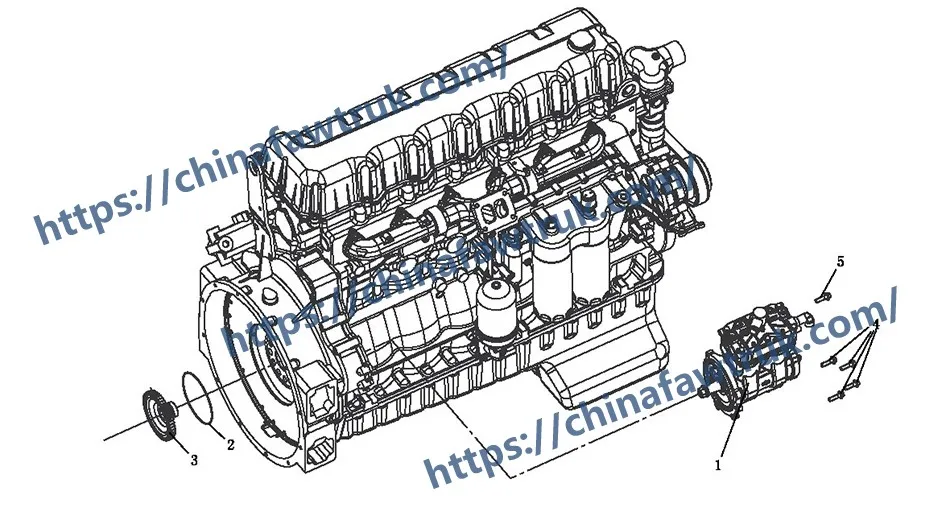

O principal componente neste diagrama é o ‘Conjunto do Compressor de Ar’ (3509010-91C). Esta é a unidade principal que normalmente é substituída como um conjunto completo durante uma falha grave. Isto não é um simples, acessório acionado por correia; é um serviço pesado, bomba integrada no motor. Neste modelo FAW, o Compressor de ar FAW é uma bomba do tipo pistão alternativo, provavelmente um design robusto de cilindro único ou duplo cilindro, projetado para alto volume, operação em serviço contínuo.

Seu funcionamento é fundamental. Ele aspira ar filtrado, comprime-o a uma alta pressão (normalmente acabou 120 PSI), e depois entrega para um governador aéreo, que por sua vez enche os tanques de ar primário e secundário do veículo. Este conjunto foi projetado para ser resfriado por líquido e lubrificado por pressão. Isso significa que possui passagens internas que se conectam diretamente aos sistemas de refrigeração e óleo do motor, é por isso que os selos associados são tão críticos.

O chefe do Compressor de ar FAW contém um conjunto de válvulas de palheta ou válvulas de gatilho para admissão e exaustão, que são projetados com precisão para lidar com altas temperaturas e pressões. Ao longo do tempo, acúmulo de carbono ou desgaste mecânico pode causar vazamento nessas válvulas, levando a uma queda na eficiência, acúmulo lento de ar, ou o compressor “passando óleo” no sistema de ar. Quando tal falha é diagnosticada, substituindo todo Compressor de ar FAW a montagem costuma ser o reparo mais confiável e eficiente em termos de tempo.

Ao contrário de um carro de passageiros, o Compressor de ar FAW não é acionado por um cinto de borracha. A energia necessária para gerar tanto ar comprimido é substancial, e o padrão de confiabilidade é muito maior. Esta montagem é acionada por engrenagem, diretamente do trem de engrenagens de distribuição interno do motor. A ‘Engrenagem Acionada pelo Compressor de Ar’ (1006047-81D) é o componente chave para esta transferência de energia.

Esta engrenagem é um serviço pesado, componente de aço endurecido, usinado com precisão com dentes de corte helicoidal. Esses dentes helicoidais engrenam com uma engrenagem motriz dentro da caixa de distribuição do motor, proporcionando um resultado positivo, alto torque, conexão antiderrapante. Este design acionado por engrenagem é excepcionalmente confiável e livre de manutenção em comparação com uma correia, mas também significa que sua instalação é mais complexa.

Esta engrenagem é pressionada ou aparafusada no próprio virabrequim do compressor. Ao instalar um novo Compressor de ar FAW, esta engrenagem deve ser transferida, ou um novo instalado. A condição desta engrenagem é crítica; qualquer lasca ou desgaste excessivo nos dentes pode introduzir detritos metálicos na caixa de distribuição do motor, levando a uma falha catastrófica do motor. É um componente de manutenção vital, representando o ponto único de entrada de energia para todo o sistema pneumático.

A lista de peças identifica um único ‘O-ring Seal’ (Q734B15000265). É impossível exagerar a importância deste, componente pequeno. Este selo é a interface primária entre o Compressor de ar FAW e o bloco do motor. Dado que o compressor é refrigerado a líquido e lubrificado por pressão, este O-ring é uma vedação multifuncional de importância crítica.

Este único anel de vedação é responsável por vedar múltiplas passagens simultaneamente enquanto o compressor é aparafusado ao motor.

Este anel de vedação é feito de um material especial, alta temperatura, material resistente a óleo (como Viton) projetado para suportar o ambiente hostil de um motor diesel. É um “uso único” papel. Sempre que o Compressor de ar FAW é removido por qualquer motivo, este selo *deve* ser substituído. Reutilizando um antigo, comprimido, ou anel de vedação endurecido por calor é uma garantia de vazamento. Esta única parte, embora custe muito pouco, é essencial para um reparo confiável.

Os componentes finais da lista são os fixadores que fixam fisicamente o Compressor de ar FAW para a caixa de engrenagens do motor. A lista pede dois números de peça diferentes: quatro unidades de 'parafuso de flange hexagonal, Haste Grossa (Tipo padrão)’ (Q1841035) e uma unidade de (Q1841025). Esse 4+1 padrão é típico para montagem pesada, acessórios de alta vibração.

Os quatro parafusos Q1841035 são provavelmente os principais parafusos de montagem, enquanto o único parafuso Q1841025 provavelmente tem um comprimento diferente, talvez usado para um local com espessura de flange diferente ou para fixar um suporte. Estes não são parafusos padrão de loja de ferragens. Eles são 'parafusos de flange', o que significa que a cabeça tem uma arruela integrada. Este design distribui a força de fixação por uma área mais ampla, evitando que a cabeça do parafuso penetre no flange do compressor de alumínio ou ferro fundido e criando uma segurança, junta resistente a vibrações.

Estes também são ‘Tipo Padrão’ parafusos de haste grossa, indicando um determinado (e provavelmente alto) resistência à tracção (Por exemplo, Aula 8.8 ou 10.9) projetado para lidar com a constante, vibração martelante do motor diesel e do compressor alternativo. Usando o correto, parafusos especificados de fábrica e apertá-los com a especificação de torque precisa é a única maneira de garantir o peso pesado Compressor de ar FAW não vibra nem quebra seu flange de montagem.

A tabela a seguir fornece a discriminação detalhada dos componentes para o Compressor de ar FAW e sua montagem, conforme especificado para o trator FAW CA4251P66K24T1A3E5.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 3509010-91C | Conjunto de compressor de ar | 1 |

| 2 | Q734B15000265 | Vedação do anel de o | 1 |

| 3 | 1006047-81D | Engrenagem acionada por compressor de ar | 1 |

| 4 | Q1841035 | Parafuso de flange hexadecimal, Haste Grossa (Tipo padrão) | 4 |

| 5 | Q1841025 | Parafuso de flange hexadecimal, Haste Grossa (Tipo padrão) | 1 |

As especificações para o Compressor de ar FAW são definidos por seu papel crítico como um componente de segurança. O sistema foi projetado para alta confiabilidade e integração direta com o motor.

| Aplicação em veículos | FAW Jiefang CA4251P66K24T1A3E5 6×4 Trator |

| Grupo de Componentes | Sistema Compressor de Ar |

| Número da peça pai | 3509010-91C (Conjunto de compressor de ar) |

| Tipo de unidade | Acionado por engrenagem (Parte não. 1006047-81D) |

| Tipo de Lubrificação | Pressurizado (Óleo do motor) |

| Tipo de resfriamento | Resfriado por líquido (Líquido refrigerante do motor) |

| Selo de Interface Primária | 1x anel de vedação (Q734B15000265) |

| Fixadores de montagem | 4x Q1841035, 1xQ1841025 (Parafusos de flange sextavados) |

| Função Primária | Gera ar comprimido para o freio a ar do veículo, suspensão, e sistemas auxiliares. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.