Bienvenido a esta guía técnica crítica sobre la Conjunto de marcha atrás FAW, el completo “ocioso” Juego de engranajes para la transmisión manual en FAW Jiefang CA4251P66K24T1A3E5 6.×4 tractor semirremolque diésel. Este conjunto es el único responsable de permitir que el vehículo retroceda..

El Conjunto de marcha atrás FAW Es un sistema de engranajes de alta resistencia con una lógica simple pero crítica.. No está en constante engrane con el conjunto de engranajes principal.. En cambio, es un separado “ocioso” engranaje que se mueve físicamente a su lugar mediante el varillaje de cambio del conductor, Invertir intencionalmente el flujo de potencia al eje principal..

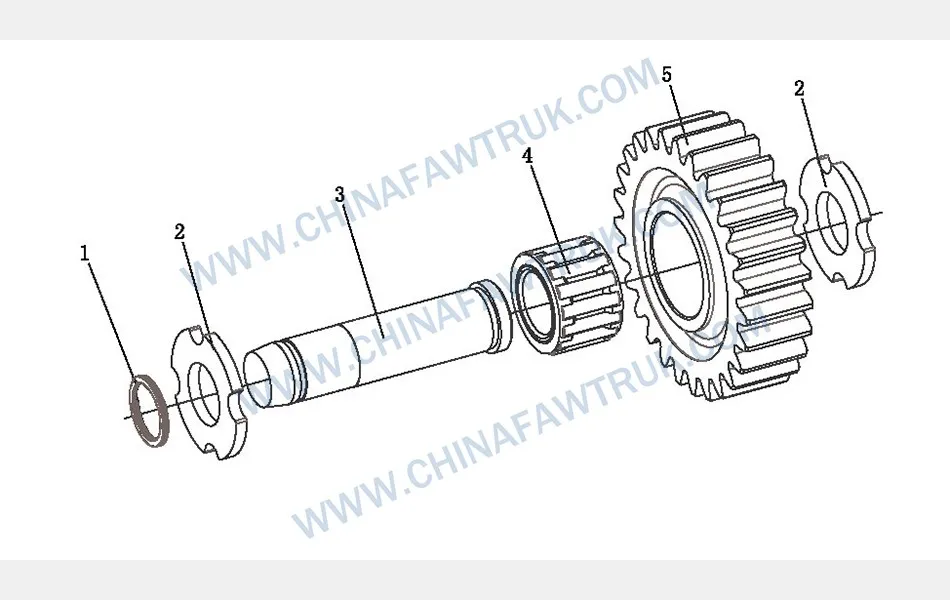

Esta guía detallada es un recurso esencial para técnicos profesionales de transmisiones y especialistas en repuestos.. Deconstruiremos todo Conjunto de marcha atrás FAW en su 5 componentes reparables, incluyendo el 'Engranaje loco de marcha atrás’ (1701481-A7G), el 'eje loco’ (1701482-A0L), su 'Rodamiento de agujas', y todo el hardware de localización crítico.

El corazón de la Conjunto de marcha atrás FAW es el 'engranaje loco de marcha atrás’ (1701481-A7G). Este es un trabajo pesado, Engranaje de acero forjado diseñado con precisión para manejar el alto torque., Demandas de baja velocidad al mover un tractor completamente cargado en reversa..

A diferencia del corte helicoidal (angular) engranajes utilizados para el movimiento hacia adelante (que son silenciosos y suaves), Este equipo suele ser un “estimular” engranaje, con dientes de corte recto. Este diseño de corte recto es mecánicamente más simple e increíblemente resistente., capaz de soportar la alta carga de impacto de ser “se deslizó” en malla. Esto es lo que produce la característica “gimoteo” sonido al conducir en reversa.

Cuando el conductor selecciona marcha atrás, una horquilla de cambio desliza esta “marcha loca de marcha atrás”’ en una posición muy específica: *entre* el engranaje impulsor de marcha atrás del contraeje y el manguito sincronizador de marcha atrás del eje principal. Este es el “lógica” del Conjunto de marcha atrás FAW. Introduciendo una tercera marcha en la ruta de potencia. (Contraeje -> Engranaje loco -> Eje principal), invierte la dirección del eje principal, haciendo que el camión retroceda.

Los dientes de este engranaje deben estar perfectamente formados y endurecidos.. Un diente astillado o roto en este único engranaje hará que la marcha atrás no funcione y enviará fragmentos de acero endurecido a lo largo de toda la transmisión., destruyendo otros engranajes y cojinetes. Esto hace que la calidad del Conjunto de marcha atrás FAWEl engranaje principal es crítico..

El engranaje loco de marcha atrás’ no flota; gira sobre el 'eje loco’ (1701482-A0L). este es el estacionario “eje” para todo Conjunto de marcha atrás FAW. Este eje es de gran diámetro., rectificado de precisión, y varilla de acero cementado.

Este eje está montado de forma segura. (a menudo encajados a presión o atornillados) en la caja de la transmisión. Debe estar perfectamente paralelo al eje principal y al contraeje para garantizar que cuando el engranaje loco se deslice y engrane, los dientes del engranaje están perfectamente alineados.

Cualquier desgaste, tanteo, o doblarse en este eje es una falla crítica. Si el eje está desgastado, el engranaje loco podrá “tambalearse” en su eje. Esta oscilación provocará un fuerte, gruñido en reversa y, más peligrosamente, impedirá que los dientes del engranaje engranen correctamente. Esto puede hacer que el engranaje “salir” bajo carga o, en el peor de los casos, romper los dientes del engranaje. El 'eje loco’ es la base rígida de la Conjunto de marcha atrás FAW.

El engranaje loco de marcha atrás’ (1701481-A7G) debe poder girar libremente sobre el 'eje loco'’ con mínima fricción. Este es el trabajo del 'Rodamientos de agujas'’ (1701485-A7G). esta es la clave “antifricción” componente de la Conjunto de marcha atrás FAW.

Este rodamiento es un “enjaulado” juego de rodillos de acero de pequeño diámetro (agujas). Se presiona en el orificio del engranaje loco.. Este diseño se elige por su extremadamente alta **capacidad de carga radial** en un espacio muy compacto. Permite que el engranaje soporte las inmensas fuerzas de separación creadas cuando los dientes del engranaje están bajo torsión..

Este cojinete es lubricado por el “chapoteo” sistema de lubricación. Una falla de este rodamiento es una falla común en un vehículo de alto kilometraje. Conjunto de marcha atrás FAW. Generalmente se diagnostica como un sonido ruidoso., agudo “gimoteo” o “retumbar” Eso solo ocurre cuando el camión está en reversa. (ya sea en movimiento o estacionario con el embrague fuera). Si este rodamiento colapsa, el engranaje se atascará en el eje o se destruirá, resultando en una pérdida total de reversa.

Los dos últimos componentes del Conjunto de marcha atrás FAW son responsables de “juego final” control y seguridad.

**'Junta/arandela – engranaje loco de marcha atrás’ (1701487-A7G):** La lista de piezas requiere dos de estos.. Estos no son “juntas”; son **arandelas de empuje**. estos estan endurecidos, rectificado de precisión, y arandelas de acero pulido que se colocan a cada lado del engranaje loco (entre el engranaje y la caja de transmisión/circlip). Su trabajo es absorber la **carga axial** (la fuerza hacia adelante y hacia atrás) que se genera cuando el engranaje se desliza hacia el engrane. Proporcionan una baja fricción, superficie de desgaste reemplazable. Las arandelas de empuje desgastadas son la causa principal de un “descuidado” sensación de la palanca de cambios o una transmisión que “salta” fuera de reversa.

**'circlip – eje loco inverso’ (1701488-A7G):** Este es el componente de retención final.. este grande “anillo de presión” (anillo de seguridad) se coloca en una ranura cortada en el "eje loco". Actúa como final “parada difícil,” impidiendo que todo el montaje (el engranaje, cojinete, y arandelas de empuje) de deslizarse fuera del extremo del eje. Es una pieza de un solo uso.; un circlip fatigado que se reutiliza puede fallar, permitiendo que toda la Conjunto de marcha atrás FAW desmoronarse dentro de la transmisión.

La siguiente tabla proporciona la información completa, desglose detallado de todos 5 componentes identificados en el 'Conjunto de marcha atrás’ diagrama para el tractor FAW CA4251P66K24T1A3E5. Una reconstrucción del Conjunto de marcha atrás FAW requiere reemplazar todos los rodamientos, lavadoras, y circlips.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1701488-A7G | clip de seguridad – eje loco inverso | 1 |

| 2 | 1701487-A7G | Junta/arandela – engranaje loco de marcha atrás | 2 |

| 3 | 1701482-A0L | Eje loco | 1 |

| 4 | 1701485-A7G | Rodamiento de agujas | 1 |

| 5 | 1701481-A7G | Engranaje loco de marcha atrás | 1 |

Las especificaciones para el Conjunto de marcha atrás FAW se definen por su función como un alto par, sistema de engranaje loco de malla deslizante. todo el Conjunto de marcha atrás FAW es un conjunto combinado de componentes.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Conjunto de marcha atrás FAW |

| N/P del engranaje principal | 1701481-A7G (Engranaje loco de marcha atrás) |

| N/P del eje principal | 1701482-A0L (Eje loco) |

| Tipo de rodamiento | 1x Rodamiento de agujas (1701485-A7G) |

| Tipo de engranaje | Corte recto (Corte recto) Engranaje loco |

| Método de actuación | Malla deslizante (a través de Shift Fork) |

| Control de empuje | 2x Arandelas de empuje (1701487-A7G) |

| Cierre de seguridad | 1x Circlip (1701488-A7G) |

| Función primaria | Para insertar entre el contraeje y el eje principal., invertir la dirección del flujo de energía. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.