Welcome to this critical technical guide on the FAW Reverse Gear Assembly, the complete “idler” gearset for the manual transmission in the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This assembly is solely responsible for enabling the vehicle to move backward.

The FAW Reverse Gear Assembly is a high-strength gear system with a simple but critical logic. It is not in constant mesh with the main gearset. Instead, it is a separate “idler” gear that is physically moved into place by the driver’s shift linkage, intentionally reversing the flow of power to the main shaft.

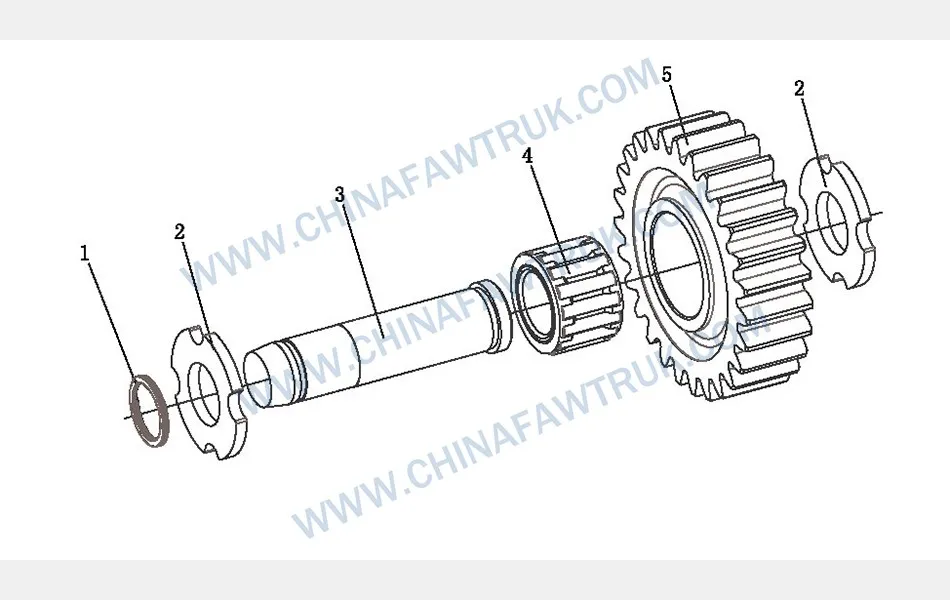

This in-depth guide is an essential resource for professional transmission technicians and parts specialists. We will deconstruct the entire FAW Reverse Gear Assembly into its 5 serviceable components, including the ‘Reverse idler gear’ (1701481-A7G), the ‘Idler shaft’ (1701482-A0L), its ‘Needle roller bearing’, and all critical locating hardware.

The heart of the FAW Reverse Gear Assembly is the ‘Reverse idler gear’ (1701481-A7G). This is a heavy-duty, forged steel gear that is precisely engineered to handle the high-torque, low-speed demands of moving a fully-loaded tractor in reverse.

Unlike the helical-cut (angled) gears used for forward motion (which are quiet and smooth), this gear is typically a “spur” gear, with straight-cut teeth. This straight-cut design is mechanically simpler and incredibly strong, able to withstand the high shock-load of being “slid” into mesh. This is what produces the characteristic “whine” sound when driving in reverse.

When the driver selects reverse, a shift fork slides this ‘Reverse idler gear’ into a very specific position: *between* the counter-shaft’s reverse drive gear and the main shaft’s reverse synchronizer sleeve. This is the “logic” of the FAW Reverse Gear Assembly. By introducing a third gear into the power path (Counter-shaft -> Idler Gear -> Main Shaft), it reverses the direction of the main shaft, causing the truck to move backward.

The teeth on this gear must be perfectly formed and hardened. A chipped or broken tooth on this single gear will make reverse inoperable and will send hardened steel fragments throughout the entire transmission, destroying other gears and bearings. This makes the quality of the FAW Reverse Gear Assembly‘s main gear critical.

The ‘Reverse idler gear’ does not float; it spins on the ‘Idler shaft’ (1701482-A0L). This is the stationary “axle” for the entire FAW Reverse Gear Assembly. This shaft is a large-diameter, precision-ground, and case-hardened steel rod.

This shaft is mounted securely (often press-fit or bolted) into the transmission housing. It must be perfectly parallel to the main shaft and counter-shaft to ensure that when the idler gear slides into mesh, the gear teeth are perfectly aligned.

Any wear, scoring, or bending on this shaft is a critical failure. If the shaft is worn, the idler gear will be able to “wobble” on its axis. This wobble will cause a loud, growling noise in reverse and, more dangerously, will prevent the gear teeth from meshing correctly. This can cause the gear to “pop out” under load or, in a worst-case scenario, shatter the gear teeth. The ‘Idler shaft’ is the rigid foundation of the FAW Reverse Gear Assembly.

The ‘Reverse idler gear’ (1701481-A7G) must be able to spin freely on the ‘Idler shaft’ with minimal friction. This is the job of the ‘Needle roller bearing’ (1701485-A7G). This is the key “anti-friction” component of the FAW Reverse Gear Assembly.

This bearing is a “caged” set of small-diameter steel rollers (needles). It is pressed into the bore of the idler gear. This design is chosen for its extremely high **radial load capacity** in a very compact space. It allows the gear to support the immense separating forces created when the gear teeth are under torque.

This bearing is lubricated by the transmission’s “splash” oiling system. A failure of this bearing is a common fault in a high-mileage FAW Reverse Gear Assembly. It is typically diagnosed as a loud, high-pitched “whine” or “rumble” that only occurs when the truck is in reverse (either moving or stationary with the clutch out). If this bearing collapses, the gear will seize to the shaft or be destroyed, resulting in a total loss of reverse.

The final two components of the FAW Reverse Gear Assembly are responsible for “end-play” control and security.

**’Gasket/Washer – reverse idler gear’ (1701487-A7G):** The parts list calls for two of these. These are not “gaskets”; they are **thrust washers**. These are hardened, precision-ground, and polished steel washers that are placed on either side of the idler gear (between the gear and the transmission case/circlip). Their job is to absorb the **axial load** (the fore-and-aft force) that is generated as the gear is slid into mesh. They provide a low-friction, replaceable wear surface. Worn-out thrust washers are a primary cause of a “sloppy” shifter feel or a transmission that “jumps” out of reverse.

**’Circlip – reverse idler shaft’ (1701488-A7G):** This is the final retaining component. This large “snap ring” (circlip) is fitted into a groove cut into the ‘Idler shaft’. It acts as the final “hard stop,” preventing the entire assembly (the gear, bearing, and thrust washers) from sliding off the end of the shaft. It is a single-use part; a fatigued circlip that is re-used can fail, allowing the entire FAW Reverse Gear Assembly to fall apart inside the transmission.

The following table provides the complete, detailed breakdown of all 5 components identified in the ‘Reverse Gear Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. A rebuild of the FAW Reverse Gear Assembly requires replacing all bearings, washers, and circlips.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701488-A7G | Circlip – reverse idler shaft | 1 |

| 2 | 1701487-A7G | Gasket/Washer – reverse idler gear | 2 |

| 3 | 1701482-A0L | Idler shaft | 1 |

| 4 | 1701485-A7G | Needle roller bearing | 1 |

| 5 | 1701481-A7G | Reverse idler gear | 1 |

The specifications for the FAW Reverse Gear Assembly are defined by its function as a high-torque, sliding-mesh idler gear system. The entire FAW Reverse Gear Assembly is a matched set of components.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Reverse Gear Assembly |

| Main Gear P/N | 1701481-A7G (Reverse idler gear) |

| Main Shaft P/N | 1701482-A0L (Idler shaft) |

| Bearing Type | 1x Needle roller bearing (1701485-A7G) |

| Gear Type | Spur-Cut (Straight-Cut) Idler Gear |

| Actuation Method | Sliding-Mesh (via Shift Fork) |

| Thrust Control | 2x Thrust Washers (1701487-A7G) |

| Security Fastener | 1x Circlip (1701488-A7G) |

| Primary Function | To be inserted between the counter-shaft and main shaft, reversing the direction of power flow. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.