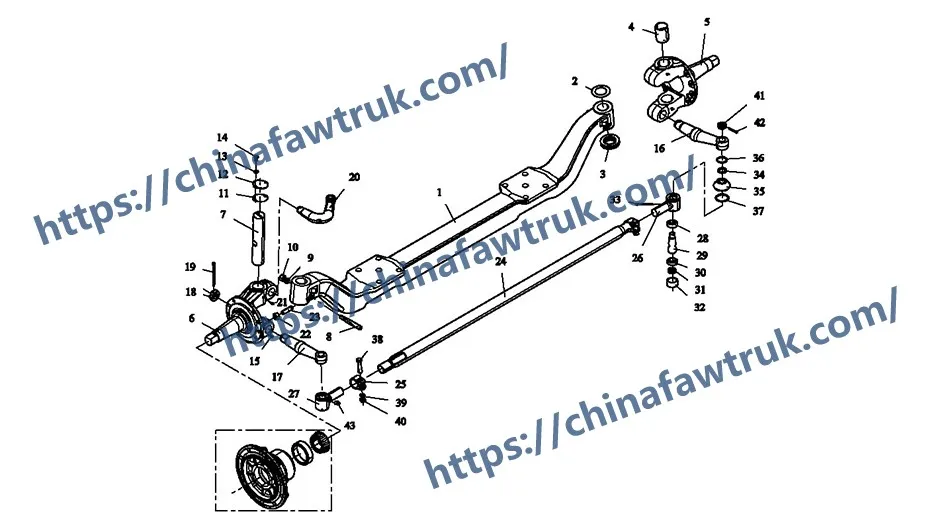

Esta es una guía técnica completa para el Conjunto de eje delantero FAW J6P (Model 3000010-14B) Para FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado. Esta deconstrucción analiza 43 piezas reparables, from the main axle beam and steering knuckles to the complete drag link and tie rod assemblies.

El Conjunto de eje delantero FAW J6P is the foundation of the vehicle’s steering and front-end load-bearing capabilities. As a non-driven “haz yo” eje, its primary role is to support the immense weight of the engine and cab, while providing a robust, stable platform for the steering mechanism. En un camión volquete pesado, this component is over-engineered to withstand severe shock loads, twisting forces, and constant impacts from off-road environments. This analysis will break down the three core systems: the axle beam and kingpin knuckles, the drag link (steering input), and the tie rod (wheel synchronization). Un mantenimiento adecuado Conjunto de eje delantero FAW J6P is non-negotiable for steering precision, vehicle safety, and managing tire wear.

This group represents the core structural components of the Conjunto de eje delantero FAW J6P. It includes the main beam that bears the vehicle’s load and the pivot points for the wheels.

1. Componente: ‘Axle’ (3001011-242) – Cantidad 1

Este (compensación 1, subparte) is the main ‘I-beam’. es un solo, forged piece of high-tensile steel that provides maximum vertical strength with minimal weight. This is the backbone of the entire Conjunto de eje delantero FAW J6P, connecting the two front leaf springs and supporting the entire front end.

2. Componente: ‘Left/Right steering knuckle’ (3001015-14B, 3001022-14B) – Cantidad 1 cada

Estos (compensación 5 & 6) son los grandes, C-shaped components that hold the wheel hubs. They attach to the ends of the axle beam via the kingpins, allowing the wheels to pivot for steering. Estos son críticos, high-stress parts of the Conjunto de eje delantero FAW J6P.

3. Componente: Piedra angular & Bearing Group (3001044-4mi, 3001040-14B-C00)

Este (compensación 7, 3) es el Kingpin Logic, the pivot on which the steering knuckle turns. It includes the ‘Main pin-steering knuckle’ (compensación 7) and the ‘Thrust bearing-kingpin’ (compensación 3). This bearing is critical, as it supports the entire vertical load of the truck at the pivot point, allowing for low-friction steering.

4. Componente: ‘Shim-front steering knuckle’ (3001041-4mi) – Cantidad según requerimiento.

Este (compensación 2) is a set of precision shims in various thicknesses. El Kingpin Pre-load Logic is a vital assembly step. These shims are used to set the precise vertical “jugar” or pre-load on the kingpin bearings. Incorrect shimming in the Conjunto de eje delantero FAW J6P will lead to either steering wobble (too loose) or bearing seizure (too tight).

The drag link is the component that transfers the steering wheel’s input (from the steering box pitman arm) hacia Conjunto de eje delantero FAW J6P, initiating the turn.

1. Componente: ‘Drag link assy’ (3003050-174) – Cantidad 1

Este (compensación 24) is the complete drag link assembly. It is a non-adjustable rod with ball joints at each end, designed to transmit pushing and pulling forces. This is the primary link between the chassis-mounted steering box and the axle-mounted Conjunto de eje delantero FAW J6P.

2. Componente: ‘Ball stud’ (3003032-1h) & ‘Ball socket’ (3003066-1h)

Estos (compensación 29, 30) are the serviceable inner components of the drag link ends. El Lógica de rótula allows the link to move up and down with the suspension while simultaneously pivoting to steer. ‘Ring spring’ (compensación 25) y 'Gorra’ (compensación 32) hold this joint together under tension.

3. Componente: ‘Seal’ & ‘Dust Cover’ (3003071-1h, 3003074-4mi)

Este (compensación 35, 34) is the vital protection system. The ‘Seal’ and ‘Dust cover’ (with its ‘Springs’, compensación 36/37) evitar el agua, suciedad, and grit from entering the ball joint. A failed seal is the number one cause of drag link failure in the Conjunto de eje delantero FAW J6P, as it allows the grease (CQ70001, compensación 43) to be contaminated.

The tie rod is the component that connects the left and right steering knuckles *together*. This ensures that both wheels turn in unison and at the correct angles (Ackermann geometry).

1. Componente: ‘Left ball joint assy-drag link’ (3003055-1h) & ‘Connecting rod-drag link’ (3003060-1h)

Este (compensación 27, 26) forms the complete tie rod. Unlike the drag link, this assembly is adjustable. The ‘Connecting rod’ (the main tube) has threaded ends, allowing the ‘Left ball joint’ (tie rod end) to be screwed in or out.

2. Componente: ‘Hex castle nut’ (CQ38736) & 'Chaveta’ (Q5006070)

Este (compensación 18, 19) es el Safety Fastener Logic. The ball joint studs on the Conjunto de eje delantero FAW J6P are secured with castle nuts. A cotter pin is then inserted through the nut and the stud, making it physically impossible for the nut to vibrate loose. This is a non-negotiable safety feature.

3. Componente: ‘Hexagon jam nut’ (CQ38722) – Cantidad 2

Este (compensación 41) es el “nuez de mermelada” on the tie rod. El Toe Adjustment Logic is performed here. A technician rotates the central connecting rod (compensación 26) to set the ‘toe-in’ or ‘toe-out’ of the front wheels. Once the alignment is perfect, these jam nuts are tightened against the tie rod ends to lock the setting in place. This is the most common alignment procedure for the Conjunto de eje delantero FAW J6P.

La siguiente tabla proporciona la información completa, desglose detallado de todos 43 tipos de componentes en el Conjunto de eje delantero FAW J6P (3000010-14B) Para FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado. This list is essential for ordering spare parts and performing a complete service of the GoJ6P Front Axle Assembly.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 3000010-14B | Front axle assy | 1 | |

| 1 | 3001011-242 | Eje | 1 |

| 2 | 3001041-4mi | Shim-front steering knuckle | Como se requiere. |

| 3001042-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3001043-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3001049-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3001051-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3001052-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3001053-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3001054-4mi | Shim-front steering knuckle | Como se requiere. | |

| 3 | 3001040-14B-C00 | Thrust bearing-kingpin | 2 |

| 4 | 3001026AA8S | Bushing-steering knuckle | 4 |

| 5 | 3001020-14B | Nudillo de dirección derecha & conjunto de casquillo | 1 |

| 3001022-14B | Nudillo de dirección derecha | 1 | |

| 6 | 3001015-14B | Left steering knuckle & conjunto de casquillo | 1 |

| 3001021-14B | Left steering knuckle | 1 | |

| 7 | 3001044-4mi | Main pin-steering knuckle | 2 |

| 8 | 3001046-4mi | Lock pin-steering knuckle main pin | 2 |

| 9 | Q40314 | arandela de resorte | 2 |

| 10 | CQ34014 | Nuez hexagonal | 2 |

| 11 | Arandela de sello | 2 | |

| 12 | 3001047-A3S | Cover-steering knuckle main pin hole | 4 |

| 13 | Q40308 | arandela de resorte | 8 |

| 14 | CQ1500814 | Perno guía de cabeza hexagonal | 8 |

| 15 | Q5510832 | llave de aspa | 3 |

| 16 | 3001032-14B | Right steering arm | 1 |

| 17 | 3001031-14B | Left steering arm | 1 |

| 18 | CQ38736 | Hex castle nut | 3 |

| 19 | Q5006070 | Alfiler | 3 |

| 20 | 3001034-14B | Steering knuckle upper arm | 1 |

| 21 | CQ70001 | Engrasador tipo recto | 4 |

| 22 | CQ34116 | Nuez hexagonal | 2 |

| 23 | 3001036-4mi | Stop block-steering knuckle | 2 |

| 24 | 3003050-174 | Drag link assy | 1 |

| 3003054-174 | Drag link | 1 | |

| 25 | 3003056-1h | Ring spring-drag link | 1 |

| 26 | 3003060-1h | Connecting rod-drag link | 1 |

| 3003062-1h | Connecting rod-drag link | 1 | |

| 27 | 3003055-1h | Left ball joint assy-drag link | 1 |

| 3003061-1h | Left ball joint-drag link | 1 | |

| 28 | 3003067-1h | Ball stud-drag link ball joint | 2 |

| 29 | 3003032-1h | Ball stud | 2 |

| 30 | 3003066-1h | Ball socket-drag link ball joint | 2 |

| 31 | 3003068-01 | Pin-drag link | 2 |

| 32 | 3003069-1h | Cap-drag link ball joint | 2 |

| 33 | Q5005080 | Alfiler | 2 |

| 34 | 3003074-4mi | Dust cover-drag link ball joint seal | 2 |

| 35 | 3003071-1h | Seal-drag link ball joint | 2 |

| 36 | 3003077-4mi | Spring-drag link ball joint seal cover | 2 |

| 37 | 3003076-4mi | Spring-drag link ball joint seal cover | 2 |

| 38 | CQ1501460 | Perno guía de cabeza hexagonal | 2 |

| 39 | Q40314 | arandela de resorte | 2 |

| 40 | CQ34014 | Nuez hexagonal | 2 |

| 41 | CQ38722 | Hex castle nut | 2 |

| 42 | Q5005045 | Alfiler | 2 |

| 43 | CQ70001 | Engrasador tipo recto | 2 |

Las especificaciones para el Conjunto de eje delantero FAW J6P are defined by its robust I-beam construction and heavy-duty steering linkage, designed for the demanding environment of a 6×4 camión volcado. Comprender estas especificaciones es clave para ordenar el producto correcto. Conjunto de eje delantero FAW J6P regiones.

| Solicitud de vehículo | FAW Jiefang CA3250P66K2L1T1E 6×4 Camión de la basura |

| Grupo de sistema | Conjunto de eje delantero FAW J6P |

| Modelo de eje | 3000010-14B |

| Tipo de eje | Non-Driven I-Beam (Steer Axle) |

| Componente central | ‘Axle’ (3001011-242) |

| Steering Linkage 1 | ‘Drag link assy’ (3003050-174) |

| Steering Linkage 2 | ‘Left ball joint assy-drag link’ (3003055-1h) (Esos género) |

| Kingpin Bearing | ‘Thrust bearing-kingpin’ (3001040-14B-C00) |

| Kingpin Adjustment | ‘Shim-front steering knuckle’ (3001041-4mi) (Según sea necesario) |

| Toe Adjustment | ‘Hex castle nut’ (CQ38722) on ‘Connecting rod’ (3003060-1h) |

| Tipos de componentes totales | 43 |

| Sistema asociado | Chasis / Sistema de dirección. El Conjunto de eje delantero FAW J6P es el núcleo. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.