Cab Tilt Control Mechanism: The Dual-Power Hydraulic Heart Ensuring 100% Service Accessibility in Arctic Conditions

The Cab Tilt Control Mechanism is the hydraulic powerhouse responsible for granting access to the engine bay of the FAW CA3250P66K24L1TE5Z dump truck. In the demanding environment of the Russian Federation, where routine maintenance must be performed regardless of freezing temperatures or snow accumulation, the reliability of this system is critical. This advanced assembly features a hybrid actuation strategy, combining a high-speed electric pump for daily convenience with a fail-safe manual backup for emergency situations. By integrating these two independent power sources into a cohesive unit, the Cab Tilt Control Mechanism ensures that the cab can always be raised or lowered, safeguarding technicians and minimizing downtime in the harsh reality of mining operations.

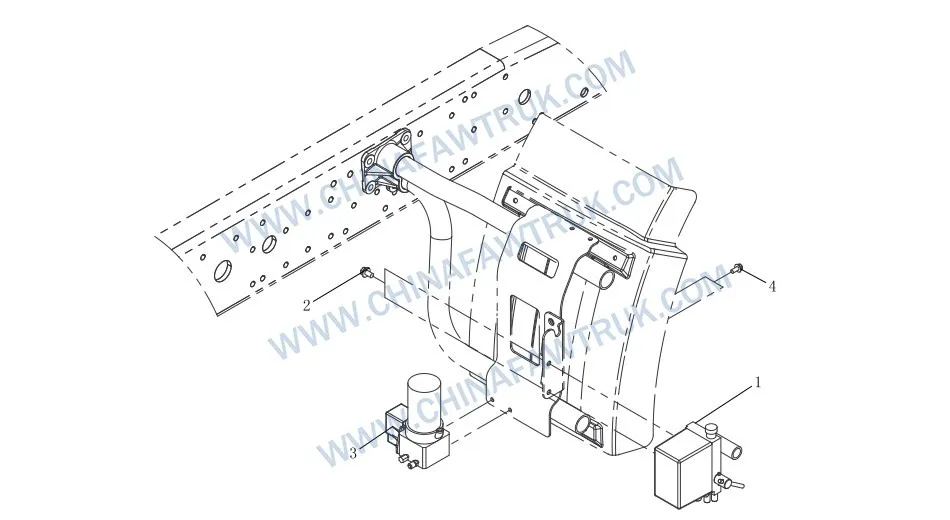

Cab Tilt Control Mechanism

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5002070A77C-C00 | Manual Pump Assembly – Cab Lift | 1 |

| 2 | CQ1461020F6 | Combination Bolt | 2 |

| 3 | 5002075AA01-C00 | Electric Hydraulic Pump Assembly – Cab Lift | 1 |

| 4 | CQ1460820F6 | Combination Bolt | 2 |

Cab Tilt Control Mechanism2

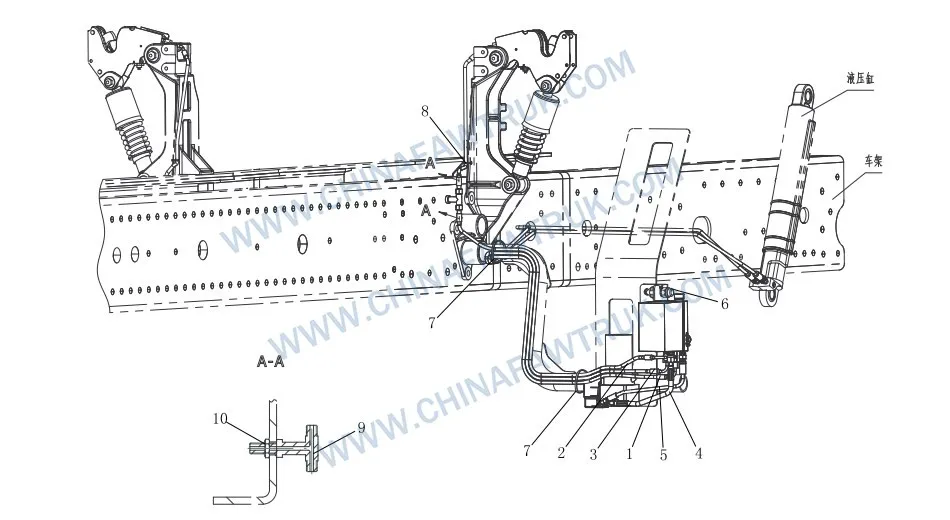

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5002080BA03 | Oil Pipe Assembly – Hydraulic Cylinder Push Port | 1 |

| 2 | 5002085-50V | Oil Pipe Assembly – Connecting Manual Pump and Tee Joint | 1 |

| 3 | 5002100BA03 | Oil Pipe Assembly – Hydraulic Cylinder Pull Port | 1 |

| 4 | 5002090AA01 | Connecting Thick Pipe Assembly | 1 |

| 5 | 5002095CA03 | Connecting Thin Pipe Assembly | 1 |

| 6 | 3735080-A01 | Hydraulic Tilt Switch Assembly | 1 |

| 7 | T67414646 | Plastic Band | 2 |

| 8 | T67410224 | Plastic Band | 1 |

| 9 | 5001156-80A | Three-way Oil Pipe Joint Body | 1 |

| 10 | CQ35112 | Hexagon Thin Nut | 1 |

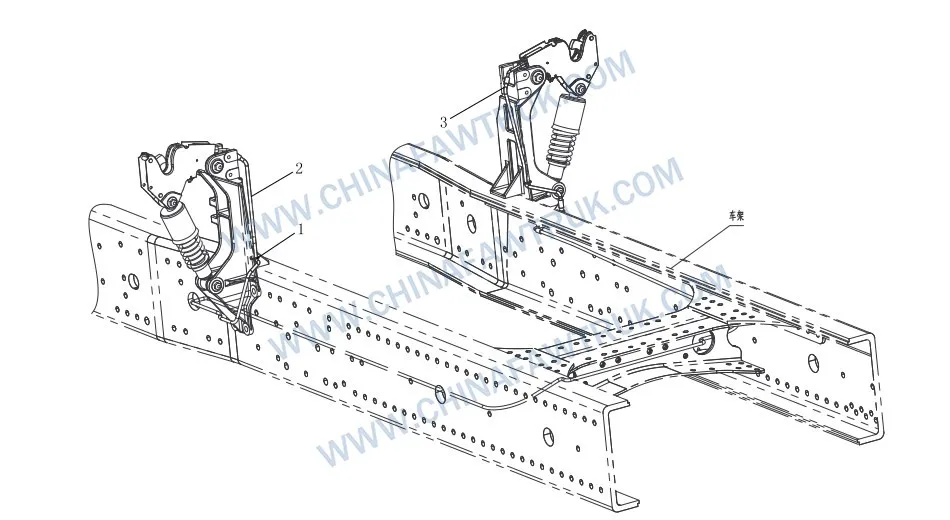

Cab Tilt Control Mechanism3

| No. |

Part Number |

Part Name |

Qty |

| 1 | T67410224 | Plastic Band | 2 |

| 2 | 5004125-14B-C00 | Oil Pipe Assembly – Connecting Left Hydraulic Lock and Tee Joint | 1 |

| 3 | 5004130-14B | Oil Pipe Assembly – Connecting Right Hydraulic Lock and Tee Joint | 1 |

The Primary Power Source: Electric Hydraulic Pump

At the core of the Cab Tilt Control Mechanism lies the Electric Hydraulic Pump Assembly – Cab Lift (Part No. 5002075AA01-C00). This sophisticated unit serves as the primary driver for raising the heavy steel cabin. In the context of the FAW J6P, the electric pump allows the driver to initiate the tilt sequence with the push of a button, eliminating the physical strain associated with manual pumping. The Cab Tilt Control Mechanism routes 24V power to a high-torque DC motor within the pump assembly, which pressurizes the hydraulic fluid to over 20 MPa. This pressure is then directed to the tilt cylinders, smoothly lifting the cab to its service position of approximately 60 degrees.

The “AA01-C00” specification of the electric pump indicates a unit optimized for cold-weather performance. Standard hydraulic pumps can struggle in the Russian winter as fluid viscosity increases, leading to motor burnout or blown fuses. The Electric Hydraulic Pump Assembly – Cab Lift incorporated into the Cab Tilt Control Mechanism features upgraded internal seals and a more powerful motor winding to overcome this viscous drag. Furthermore, the pump body includes an integrated reservoir with a specialized breather that prevents moisture ingress, ensuring that the hydraulic fluid remains uncontaminated by melting snow or ice.

Safety logic is built directly into the Cab Tilt Control Mechanism. The electric pump assembly contains check valves and flow restrictors that prevent the cab from falling freely if a hydraulic hose bursts. The Electric Hydraulic Pump Assembly – Cab Lift also interfaces with the truck’s safety interlock system, ensuring that the tilt operation can only commence when the parking brake is engaged and the gear selector is in neutral. This integration makes the Cab Tilt Control Mechanism not just a lifting tool, but a comprehensive safety system for the vehicle operator.

The Fail-Safe: Manual Pump Assembly

While electric actuation offers convenience, the harsh reality of Arctic operations demands redundancy. The Cab Tilt Control Mechanism includes a dedicated Manual Pump Assembly – Cab Lift (Part No. 5002070A77C-C00) as a completely independent backup system. In the event of a total electrical failure—a common scenario after a truck has been parked for days in -40°C—the manual pump allows the driver or mechanic to raise the cab to access the batteries and engine. The Cab Tilt Control Mechanism ensures that the vehicle remains serviceable even when it is “dead cold.”

The Manual Pump Assembly – Cab Lift is designed with a long lever arm socket to maximize mechanical advantage. This allows a single operator to generate the necessary hydraulic pressure without excessive physical exertion. The internal valving of the manual pump within the Cab Tilt Control Mechanism is separated from the electric circuit, meaning a failure in the electric pump’s check valve does not compromise the manual operation. This isolation is a critical design feature of the Cab Tilt Control Mechanism, providing a true “Plan B” for field repairs.

Constructed from high-grade cast steel and treated with anti-corrosion coatings, the Manual Pump Assembly – Cab Lift is built to withstand exposure to road salt and grime. It is typically mounted in an accessible location on the chassis, often behind the cab steps. The Cab Tilt Control Mechanism design ensures that the manual pump lever clearance is sufficient even when the truck is equipped with side fairings or mudguards, ensuring that access is never impeded during an emergency.

Precision Mounting and Structural Integrity

The mounting of the Cab Tilt Control Mechanism components to the chassis requires absolute rigidity. The electric pump is secured using two Combination Bolt fasteners (Part No. CQ1460820F6). These M8 bolts feature an integrated flange and serrated face that bite into the mounting bracket, preventing them from backing out under the high-frequency vibration of the diesel engine. The Cab Tilt Control Mechanism relies on these bolts to maintain the pump’s orientation, ensuring that the fluid pickup remains submerged in the reservoir even when the truck is parked on a steep incline.

Similarly, the manual pump is anchored by heavier M10 Combination Bolt units (Part No. CQ1461020F6). The manual pump experiences significant torque loads when the operator is pumping the handle lever. The larger diameter of these bolts within the Cab Tilt Control Mechanism provides the shear strength necessary to resist twisting forces. If these bolts were to loosen, the manual pump could shift, potentially kinking the rigid hydraulic lines connected to it. The Cab Tilt Control Mechanism engineering specifies “F6” corrosion-resistant plating for all fasteners, protecting the threads from seizing due to rust.

The hydraulic connections between the Electric Hydraulic Pump Assembly – Cab Lift, the Manual Pump Assembly – Cab Lift, and the lift cylinders are made via high-pressure steel lines and flexible hoses. The Cab Tilt Control Mechanism utilizes banjo fittings and copper crush washers at the pump interfaces to ensure leak-free performance. Maintaining the integrity of these connections is vital; a single leak in the Cab Tilt Control Mechanism can render the entire tilt system inoperative, trapping the engine beneath the cab.

Maintenance and Troubleshooting

Regular maintenance of the Cab Tilt Control Mechanism is essential for safety. The hydraulic fluid level in the reservoir should be checked during every service interval. Low fluid levels can cause air cavitation in the Electric Hydraulic Pump Assembly – Cab Lift, leading to jerky cab movement or pump failure. The manual pump handle pivot should be lubricated to ensure smooth operation. Fleet mechanics must also inspect the Combination Bolt fasteners for tightness, as chassis vibration can loosen them over time.

If the electric tilt fails to operate, the first diagnostic step for the Cab Tilt Control Mechanism is to check the fuse and the relay in the chassis fuse box. If power is present, the motor brushes or solenoid may be worn. In such cases, the modular design of the Cab Tilt Control Mechanism allows for the replacement of the Electric Hydraulic Pump Assembly – Cab Lift as a single unit. Attempting to rebuild the pump in the field is generally not recommended due to the precision required for the internal gear set.

Testing the Manual Pump Assembly – Cab Lift should be part of the annual inspection. Over time, the internal seals of the manual pump can dry out if unused. Cycling the manual pump through a full lift and lower sequence ensures that the seals remain lubricated and that the Cab Tilt Control Mechanism is ready for an emergency. Using genuine FAW replacement parts ensures that the pressure ratings and flow characteristics match the system design, preventing damage to the lift cylinders.

Conclusion: Unlocking Serviceability

The Cab Tilt Control Mechanism is the gateway to the engine, enabling all major maintenance tasks on the vehicle. By combining the Electric Hydraulic Pump Assembly – Cab Lift and the Manual Pump Assembly – Cab Lift into a redundant system, FAW ensures that access is never denied. The 4 components listed—the two pumps and their mounting bolts—form the core of this critical system.

For fleet managers, the Cab Tilt Control Mechanism represents the guarantee of maintainability. A stuck cab can turn a minor repair into a major logistical headache. By maintaining the pumps and hydraulic connections, and ensuring the mounting hardware is secure, operators protect their ability to service the fleet efficiently, keeping the trucks running and productive in the challenging Russian environment.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.