Mecanismo de control de inclinación de la cabina: El corazón hidráulico de doble potencia que garantiza 100% Accesibilidad al servicio en condiciones árticas

El Mecanismo de control de inclinación de la cabina es la central hidráulica responsable de otorgar acceso al compartimiento del motor del camión volquete FAW CA3250P66K24L1TE5Z. En el exigente entorno de la Federación Rusa, donde se debe realizar un mantenimiento de rutina independientemente de las temperaturas bajo cero o la acumulación de nieve, La confiabilidad de este sistema es crítica.. Este conjunto avanzado presenta una estrategia de actuación híbrida., combinando una bomba eléctrica de alta velocidad para comodidad diaria con un respaldo manual a prueba de fallas para situaciones de emergencia. Al integrar estas dos fuentes de energía independientes en una unidad cohesiva, el Mecanismo de control de inclinación de la cabina garantiza que la cabina siempre se pueda subir o bajar, proteger a los técnicos y minimizar el tiempo de inactividad en la dura realidad de las operaciones mineras.

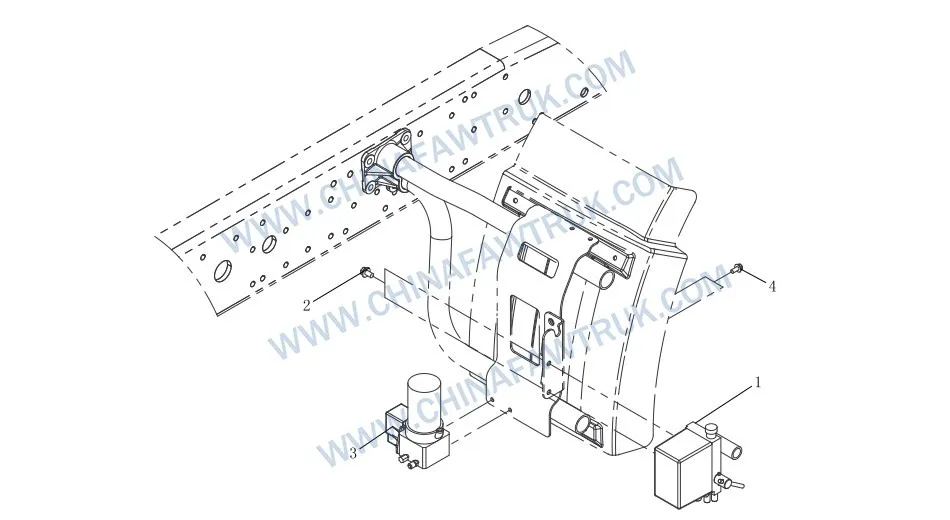

Mecanismo de control de inclinación de la cabina

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 5002070A77C-C00 | Montaje de bomba manual – Elevación de cabina | 1 |

| 2 | CQ1461020F6 | Perno combinado | 2 |

| 3 | 5002075AA01-C00 | Conjunto de bomba hidráulica eléctrica – Elevación de cabina | 1 |

| 4 | CQ1460820F6 | Perno combinado | 2 |

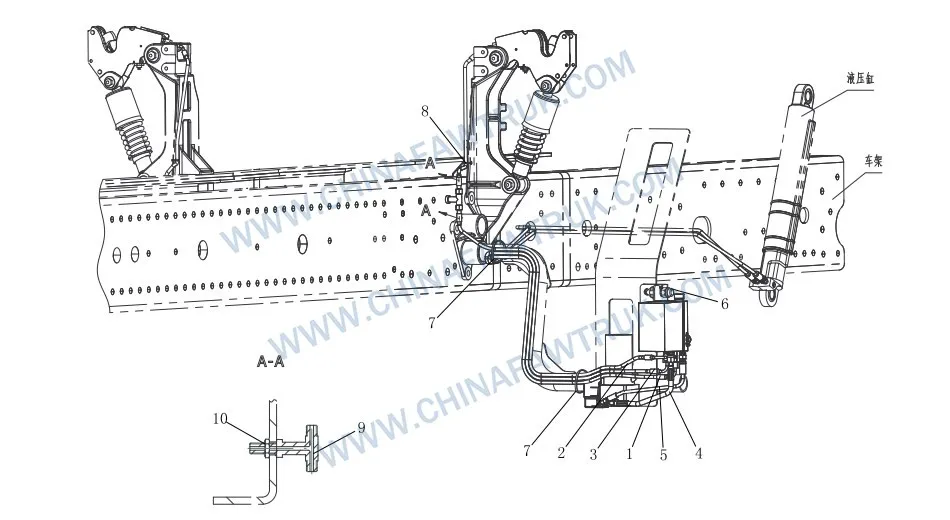

Mecanismo de control de inclinación de la cabina2

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 5002080BA03 | Conjunto de tubería de aceite – Puerto de empuje del cilindro hidráulico | 1 |

| 2 | 5002085-50V | Conjunto de tubería de aceite – Conexión de la bomba manual y la junta en T | 1 |

| 3 | 5002100BA03 | Conjunto de tubería de aceite – Puerto de extracción del cilindro hidráulico | 1 |

| 4 | 5002090AA01 | Conexión del conjunto de tubería gruesa | 1 |

| 5 | 5002095CA03 | Conexión del conjunto de tubería delgada | 1 |

| 6 | 3735080-A01 | Conjunto de interruptor de inclinación hidráulica | 1 |

| 7 | T67414646 | Banda de plastico | 2 |

| 8 | T67410224 | Banda de plastico | 1 |

| 9 | 5001156-80A | Cuerpo de junta de tubo de aceite de tres vías | 1 |

| 10 | CQ35112 | Tuerca delgada hexágono | 1 |

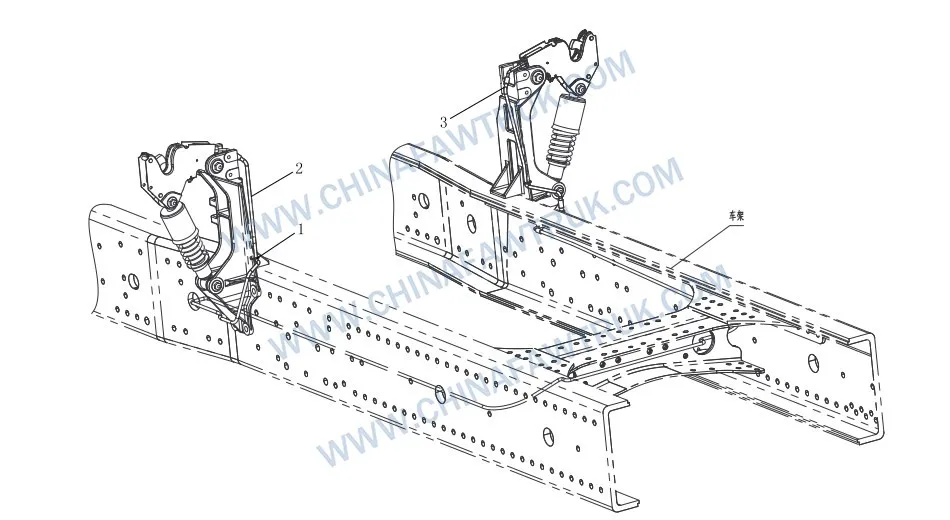

Mecanismo de control de inclinación de la cabina3

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | T67410224 | Banda de plastico | 2 |

| 2 | 5004125-14B-C00 | Conjunto de tubería de aceite – Conexión del bloqueo hidráulico izquierdo y la junta en T | 1 |

| 3 | 5004130-14B | Conjunto de tubería de aceite – Conexión del bloqueo hidráulico derecho y la junta en T | 1 |

La fuente de energía primaria: Bomba hidráulica eléctrica

En el núcleo de la Mecanismo de control de inclinación de la cabina miente el Conjunto de bomba hidráulica eléctrica – Elevación de cabina (Número de pieza. 5002075AA01-C00). Esta sofisticada unidad sirve como motor principal para elevar la pesada cabina de acero.. En el contexto del FAW J6P, La bomba eléctrica permite al conductor iniciar la secuencia de inclinación con solo presionar un botón., Eliminando la tensión física asociada con el bombeo manual.. El Mecanismo de control de inclinación de la cabina dirige la energía de 24 V a un motor de CC de alto torque dentro del conjunto de la bomba, que presuriza el fluido hidráulico a más 20 MPa. Esta presión luego se dirige a los cilindros de inclinación., levantando suavemente la cabina a su posición de servicio de aproximadamente 60 grados.

El “AA01-C00” La especificación de la bomba eléctrica indica una unidad optimizada para el rendimiento en climas fríos.. Las bombas hidráulicas estándar pueden tener problemas en el invierno ruso a medida que aumenta la viscosidad del fluido, lo que provoca que el motor se queme o se quemen los fusibles. El Conjunto de bomba hidráulica eléctrica – Elevación de cabina incorporado al Mecanismo de control de inclinación de la cabina Cuenta con sellos internos mejorados y un devanado del motor más potente para superar esta resistencia viscosa.. Además, El cuerpo de la bomba incluye un depósito integrado con un respiradero especializado que evita la entrada de humedad., Garantizar que el fluido hidráulico no se contamine por el derretimiento de la nieve o el hielo..

La lógica de seguridad está integrada directamente en el Mecanismo de control de inclinación de la cabina. El conjunto de la bomba eléctrica contiene válvulas de retención y limitadores de flujo que evitan que la cabina caiga libremente si estalla una manguera hidráulica.. El Conjunto de bomba hidráulica eléctrica – Elevación de cabina también interactúa con el sistema de bloqueo de seguridad del camión, Asegurarse de que la operación de inclinación solo pueda comenzar cuando el freno de mano esté puesto y el selector de marchas esté en punto muerto.. Esta integración hace que Mecanismo de control de inclinación de la cabina no solo una herramienta de elevación, sino un completo sistema de seguridad para el conductor del vehículo.

El a prueba de fallos: Montaje de bomba manual

Mientras que el accionamiento eléctrico ofrece comodidad, La dura realidad de las operaciones en el Ártico exige redundancia.. El Mecanismo de control de inclinación de la cabina incluye un dedicado Montaje de bomba manual – Elevación de cabina (Número de pieza. 5002070A77C-C00) como un sistema de respaldo completamente independiente. En caso de una falla eléctrica total (un escenario común después de que un camión ha estado estacionado durante días a -40 °C), la bomba manual permite al conductor o al mecánico levantar la cabina para acceder a las baterías y al motor.. El Mecanismo de control de inclinación de la cabina garantiza que el vehículo siga siendo útil incluso cuando esté “frío muerto.”

El Montaje de bomba manual – Elevación de cabina Está diseñado con un casquillo de brazo de palanca largo para maximizar la ventaja mecánica.. Esto permite que un solo operador genere la presión hidráulica necesaria sin un esfuerzo físico excesivo.. La válvula interna de la bomba manual dentro del Mecanismo de control de inclinación de la cabina está separado del circuito eléctrico, es decir, una falla en la válvula de retención de la electrobomba no compromete el funcionamiento manual. Este aislamiento es una característica de diseño crítica del Mecanismo de control de inclinación de la cabina, proporcionando una verdadera “Plan B” para reparaciones en el campo.

Construido con acero fundido de alta calidad y tratado con revestimientos anticorrosión., el Montaje de bomba manual – Elevación de cabina está construido para resistir la exposición a la sal y la suciedad de la carretera. Por lo general, se monta en una ubicación accesible en el chasis., a menudo detrás de los escalones de la cabina. El Mecanismo de control de inclinación de la cabina El diseño garantiza que el espacio libre para la palanca de la bomba manual sea suficiente incluso cuando el camión está equipado con carenados laterales o guardabarros., Garantizar que el acceso nunca se vea impedido durante una emergencia..

Montaje de precisión e integridad estructural

El montaje de la Mecanismo de control de inclinación de la cabina Los componentes del chasis requieren una rigidez absoluta.. La bomba eléctrica se fija mediante dos Perno combinado sujetadores (Número de pieza. CQ1460820F6). Estos pernos M8 cuentan con una brida integrada y una cara dentada que se introducen en el soporte de montaje., evitando que retrocedan bajo la vibración de alta frecuencia del motor diesel. El Mecanismo de control de inclinación de la cabina Se basa en estos pernos para mantener la orientación de la bomba., Asegurar que el recogedor de fluido permanezca sumergido en el depósito incluso cuando el camión esté estacionado en una pendiente pronunciada..

Similarmente, La bomba manual está anclada por M10 más pesado. Perno combinado unidades (Número de pieza. CQ1461020F6). La bomba manual experimenta cargas de torsión significativas cuando el operador bombea la palanca del mango.. El mayor diámetro de estos pernos dentro del Mecanismo de control de inclinación de la cabina Proporciona la resistencia al corte necesaria para resistir las fuerzas de torsión.. Si estos tornillos se aflojaran, la bomba manual podría cambiar, potencialmente doblar las líneas hidráulicas rígidas conectadas a él. El Mecanismo de control de inclinación de la cabina ingeniería especifica “F6” revestimiento resistente a la corrosión para todos los sujetadores, Proteger las roscas del agarrotamiento debido al óxido..

Las conexiones hidráulicas entre el Conjunto de bomba hidráulica eléctrica – Elevación de cabina, el Montaje de bomba manual – Elevación de cabina, y los cilindros de elevación se fabrican mediante líneas de acero de alta presión y mangueras flexibles.. El Mecanismo de control de inclinación de la cabina Utiliza accesorios tipo banjo y arandelas de cobre en las interfaces de la bomba para garantizar un rendimiento sin fugas.. Mantener la integridad de estas conexiones es vital; una sola fuga en el Mecanismo de control de inclinación de la cabina puede dejar inoperativo todo el sistema de inclinación, Atrapando el motor debajo de la cabina..

Mantenimiento y solución de problemas

Mantenimiento regular de la Mecanismo de control de inclinación de la cabina es esencial para la seguridad. El nivel de fluido hidráulico en el depósito debe verificarse durante cada intervalo de servicio.. Los niveles bajos de líquido pueden causar cavitación de aire en el Conjunto de bomba hidráulica eléctrica – Elevación de cabina, lo que provoca movimientos bruscos de la cabina o fallas de la bomba. El pivote del mango de la bomba manual debe lubricarse para garantizar un funcionamiento suave.. Los mecánicos de la flota también deben inspeccionar el Perno combinado sujetadores para estanqueidad, ya que la vibración del chasis puede aflojarlos con el tiempo.

Si la inclinación eléctrica no funciona, el primer paso diagnóstico para el Mecanismo de control de inclinación de la cabina es comprobar el fusible y el relé en la caja de fusibles del chasis. Si hay energía presente, Las escobillas del motor o el solenoide pueden estar desgastados.. En tales casos, el diseño modular del Mecanismo de control de inclinación de la cabina permite la sustitución del Conjunto de bomba hidráulica eléctrica – Elevación de cabina como una sola unidad. Generalmente no se recomienda intentar reconstruir la bomba en el campo debido a la precisión requerida para el conjunto de engranajes internos..

Probando el Montaje de bomba manual – Elevación de cabina debe ser parte de la inspección anual. Con el tiempo, Los sellos internos de la bomba manual pueden secarse si no se utilizan.. Realizar un ciclo de la bomba manual a través de una secuencia completa de elevación y descenso garantiza que los sellos permanezcan lubricados y que el Mecanismo de control de inclinación de la cabina está listo para una emergencia. El uso de piezas de repuesto genuinas de FAW garantiza que las clasificaciones de presión y las características de flujo coincidan con el diseño del sistema., evitando daños a los cilindros de elevación.

Conclusión: Desbloqueo de la capacidad de servicio

El Mecanismo de control de inclinación de la cabina es la puerta de entrada al motor, permitiendo todas las tareas de mantenimiento importantes en el vehículo. Al combinar el Conjunto de bomba hidráulica eléctrica – Elevación de cabina y el Montaje de bomba manual – Elevación de cabina en un sistema redundante, FAW garantiza que nunca se deniegue el acceso. El 4 Los componentes enumerados (las dos bombas y sus pernos de montaje) forman el núcleo de este sistema crítico..

Para los gerentes de flota, el Mecanismo de control de inclinación de la cabina representa la garantía de mantenibilidad. Un taxi atascado puede convertir una reparación menor en un gran dolor de cabeza logístico. Manteniendo las bombas y conexiones hidráulicas., y asegurarse de que el hardware de montaje esté seguro, Los operadores protegen su capacidad para dar servicio a la flota de manera eficiente., mantener los camiones en funcionamiento y productivos en el desafiante entorno ruso.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.