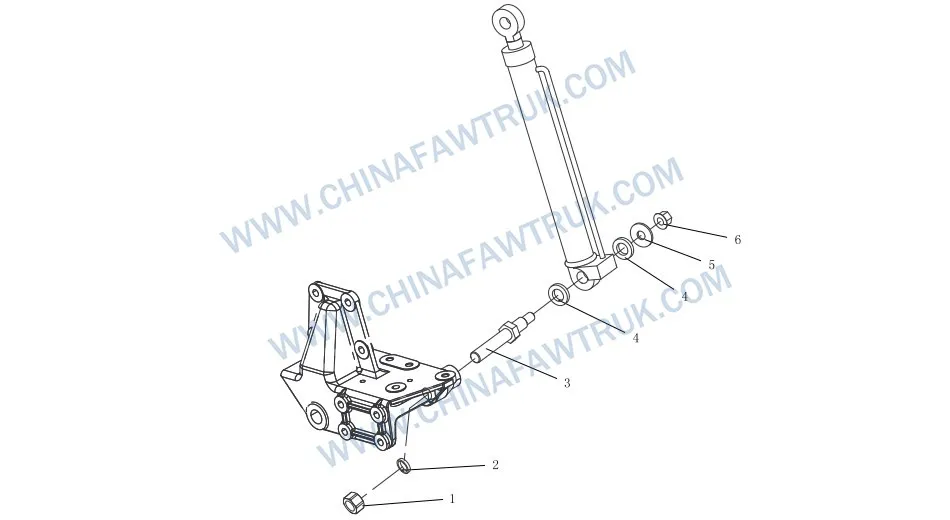

Dispositivo de soporte hidráulico para cabina: Estableciendo el punto de anclaje inferior para 6 Elementos de sujeción críticos en operaciones de inclinación en el Ártico

El Dispositivo de soporte hidráulico para cabina (Instalación inferior) is the pivotal mechanical interface that anchors the cabin lifting mechanism to the chassis of the FAW CA3250P66K24L1TE5Z dump truck. In the severe operational environment of the Russian Federation, where routine engine maintenance must be performed regardless of sub-zero temperatures, the reliability of the cabin tilt system is non-negotiable. This specific assembly focuses on the lower fixation point of the hydraulic cylinder, a high-stress area that bears the entire weight of the cab during the tilting process. By utilizing precision-machined pins, vibration-dampening soft cushions, and specialized locking hardware, el Dispositivo de soporte hidráulico para cabina ensures that the lifting geometry remains stable and secure, preventing catastrophic detachment during maintenance intervals.

Dispositivo de soporte hidráulico para cabina

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | CQ34124 | Tuerca hexagonal | 1 |

| 2 | Q40324 | Arandela de resorte | 1 |

| 3 | 5002023-76A | Pin Shaft – Hydraulic Cylinder Lower Anchor Point | 1 |

| 4 | 5002027-A01 | Soft Cushion – Hydraulic Cylinder Lower Anchor Point | 2 |

| 5 | Q40218 | Lavadora grande | 1 |

| 6 | Q32918 | Tipo 1 Non-metallic Insert Hex Lock Nut | 1 |

The Structural Pivot Logic

El Dispositivo de soporte hidráulico para cabina depends entirely on the integrity of its lower pivot point to function safely. This assembly is not a static mount; it is a dynamic hinge that must accommodate significant rotation while bearing loads that can exceed the static weight of the cab during the initial phase of lifting. The central component facilitating this action is the Pin Shaft – Hydraulic Cylinder Lower Anchor Point (Número de pieza. 5002023-76A). This shaft is precision-ground from high-tensile steel, designed to withstand the immense shear forces generated when the hydraulic cylinder pushes the cab upward against gravity and wind resistance.

En el contexto de la Dispositivo de soporte hidráulico para cabina, the surface finish of the pin shaft is critical. It must be smooth enough to allow rotation without binding, yet durable enough to resist galling under load. El “76A” specification implies a specific heat treatment or surface hardening process, likely nitriding or induction hardening, to provide a wear-resistant outer layer while maintaining a tough, núcleo dúctil. This combination is essential for the Dispositivo de soporte hidráulico para cabina to survive the shock loads of off-road driving when the cab is locked down, as well as the friction of rotation when the cab is being tilted for service.

Además, the pin shaft acts as the load transfer mechanism. The hydraulic force generated by the cylinder is transmitted through the eye of the cylinder rod, onto this pin, and then into the chassis brackets. Cualquier falla en el Dispositivo de soporte hidráulico para cabina pin would result in the immediate collapse of the lift cylinder, potentially dropping the cab dangerously. Por lo tanto, the dimensional tolerances of this pin are strictly controlled to ensure a precise fit that distributes the load evenly, preventing stress concentrations that could lead to metal fatigue over the vehicle’s lifespan.

Vibration Isolation and Bushing Technology

Un rasgo definitorio de la Dispositivo de soporte hidráulico para cabina is its integration of vibration isolation. The assembly utilizes two units of the Soft Cushion – Hydraulic Cylinder Lower Anchor Point (Número de pieza. 5002027-A01). These cushions act as the interface between the steel pin and the mounting bracket or cylinder eye. Their primary role within the Dispositivo de soporte hidráulico para cabina is to absorb high-frequency vibrations transmitted from the chassis before they can reach the hydraulic seals of the lift cylinder. Without these cushions, the rigid metal-on-metal contact would transmit every road imperfection directly into the cylinder, leading to rapid seal wear and fluid leakage.

The material composition of these soft cushions is specifically engineered for the Russian “Cold Zone.” Standard rubber bushings become rock-hard and brittle at -40°C, losing their ability to dampen vibration and often cracking under load. El Dispositivo de soporte hidráulico para cabina employs a specialized elastomer or polyurethane blend that retains flexibility in cryogenic conditions. This ensures that the damping characteristics of the Dispositivo de soporte hidráulico para cabina remain consistent year-round, protecting the hydraulic components from shock damage during winter operations on frozen, rutted haul roads.

Además, these cushions serve a pivotal role in alignment. By providing a slight degree of compliance, they allow the Dispositivo de soporte hidráulico para cabina to accommodate minor misalignments between the chassis brackets and the cab structure. This self-aligning property reduces side-loading on the hydraulic cylinder rod, which is a primary cause of bent rods and seal failure. By keeping the forces acting on the cylinder purely axial, el Dispositivo de soporte hidráulico para cabina maximizes the lifespan of the entire tilt system.

Fastening Security and Load Distribution

La integridad estructural del Dispositivo de soporte hidráulico para cabina is maintained by a robust fastening system designed to resist loosening under extreme vibration. The assembly uses a Tipo 1 Non-metallic Insert Hex Lock Nut (Número de pieza. Q32918). This is not a standard nut; it features a nylon or polymer ring insert that deforms elastically over the bolt threads. This interference fit creates a prevailing torque that prevents the nut from backing off, even under the severe shaking of a diesel engine or off-road driving. En el Dispositivo de soporte hidráulico para cabina, this locking feature is a critical safety redundancy.

Working in tandem with the lock nut is the Lavadora grande (Número de pieza. Q40218). El uso de un “Large” washer specification in the Dispositivo de soporte hidráulico para cabina es deliberado. It provides a significantly increased surface area to distribute the clamping force of the nut against the soft cushion or bracket face. This prevents the nut from embedding into the material, which would lead to a loss of preload and eventually a loose joint. The large washer also acts as a shield, protecting the bushing material from direct abrasion during the tightening process.

The assembly also lists a standard Tuerca hexagonal (Número de pieza. CQ34124) y Arandela de resorte (Número de pieza. Q40324), likely used on the opposing side or a secondary retention point of the pin. The spring washer provides active tensioning, compensating for thermal contraction of the metal parts in the Dispositivo de soporte hidráulico para cabina during rapid cooling. This multi-layered approach to fastening—utilizing friction, mechanical locking, and active tensioning—ensures that the lower anchor point remains secure for the operational life of the vehicle.

Protocolo de mantenimiento e inspección

Routine inspection of the Dispositivo de soporte hidráulico para cabina es esencial para la seguridad. The most common failure mode is the degradation of the Soft Cushion. Operators should visually inspect these cushions for cracks, tears, or excessive compression set. If the pin shaft appears to be off-center within the bushing, or if there is metal-to-metal contact visible, the cushions of the Dispositivo de soporte hidráulico para cabina have failed and must be replaced immediately to prevent damage to the cylinder.

El Pin Shaft should be checked for signs of corrosion or “stepping” (wear grooves). While the pin is hardened, the ingress of abrasive mining dust can act as a grinding paste, wearing down the shaft diameter over time. A worn pin in the Dispositivo de soporte hidráulico para cabina creates excessive play, leading to clunking noises when the cab tilts and potential binding. Lubricación, if a zerk fitting is present on the housing (though often these are dry-lube designs), should be performed according to the severe service schedule.

Finalmente, the torque on the Tipo 1 Non-metallic Insert Hex Lock Nut must be verified. Sin embargo, lock nuts should generally not be reused after removal, as the nylon insert loses its gripping power. si el Dispositivo de soporte hidráulico para cabina is disassembled for any reason, new lock nuts should always be installed. Fleet managers must ensure that the correct grade of hardware is used; substituting a standard nut for the specified lock nut compromises the safety of the entire cab tilt system.

Conclusión: The Foundation of Safe Access

El Dispositivo de soporte hidráulico para cabina (Instalación inferior) is a deceptively simple assembly that carries a heavy responsibility. que comprende solo 6 tipos de componentes, it forms the critical anchor for the cab lifting system. Its design balances the need for rigid structural support with the requirement for vibration isolation and articulation.

Para operadores de flotas, el Dispositivo de soporte hidráulico para cabina is a safety-critical checkpoint. Ensuring that the pin, cojines, and locking hardware are in good condition allows for safe and reliable engine access, which is fundamental to maintaining the truck’s powertrain. By respecting the engineering logic of this assembly and using genuine FAW replacement parts, operators protect their technicians and ensure the long-term availability of their vehicles.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.