Mecanismo de controle de inclinação da cabine: O coração hidráulico de dupla potência garante 100% Acessibilidade de serviço em condições árticas

O Mecanismo de controle de inclinação da cabine é a central hidráulica responsável por dar acesso ao compartimento do motor do caminhão basculante FAW CA3250P66K24L1TE5Z. No ambiente exigente da Federação Russa, onde a manutenção de rotina deve ser realizada independentemente de temperaturas congelantes ou acúmulo de neve, a confiabilidade deste sistema é crítica. Esta montagem avançada apresenta uma estratégia de atuação híbrida, combinando uma bomba elétrica de alta velocidade para conveniência diária com um backup manual à prova de falhas para situações de emergência. Ao integrar estas duas fontes de energia independentes numa unidade coesa, o Mecanismo de controle de inclinação da cabine garante que a cabine sempre possa ser elevada ou abaixada, protegendo os técnicos e minimizando o tempo de inatividade na dura realidade das operações de mineração.

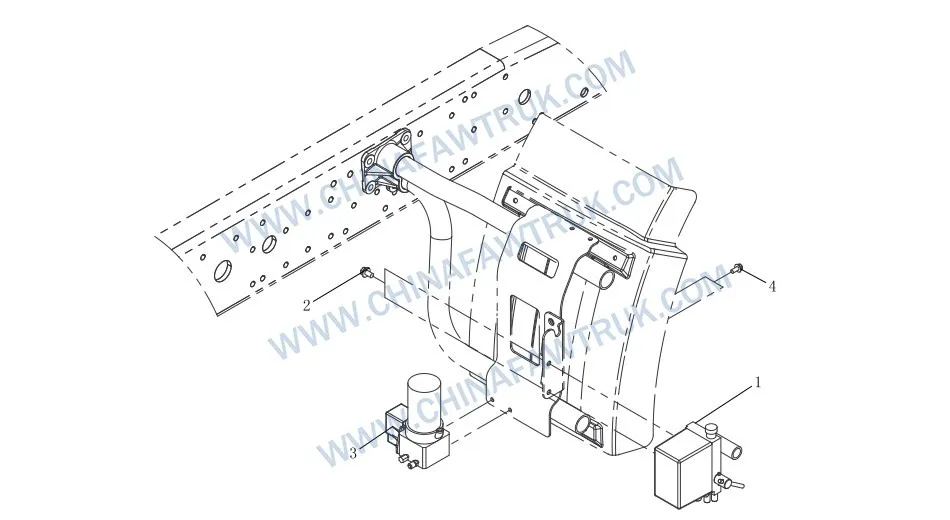

Mecanismo de controle de inclinação da cabine

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 5002070A77C-C00 | Conjunto de bomba manual – Elevador de cabine | 1 |

| 2 | CQ1461020F6 | Parafuso de combinação | 2 |

| 3 | 5002075AA01-C00 | Conjunto de bomba hidráulica elétrica – Elevador de cabine | 1 |

| 4 | CQ1460820F6 | Parafuso de combinação | 2 |

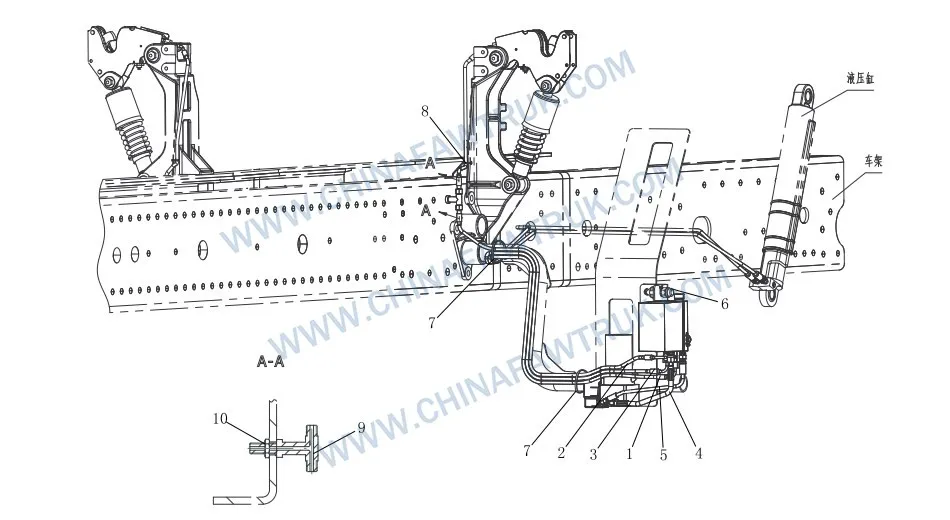

Mecanismo de controle de inclinação da cabine 2

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 5002080BA03 | Conjunto de tubo de óleo – Hydraulic Cylinder Push Port | 1 |

| 2 | 5002085-50V | Conjunto de tubo de óleo – Connecting Manual Pump and Tee Joint | 1 |

| 3 | 5002100BA03 | Conjunto de tubo de óleo – Hydraulic Cylinder Pull Port | 1 |

| 4 | 5002090AA01 | Connecting Thick Pipe Assembly | 1 |

| 5 | 5002095CA03 | Connecting Thin Pipe Assembly | 1 |

| 6 | 3735080-A01 | Hydraulic Tilt Switch Assembly | 1 |

| 7 | T67414646 | Faixa de plástico | 2 |

| 8 | T67410224 | Faixa de plástico | 1 |

| 9 | 5001156-80A | Three-way Oil Pipe Joint Body | 1 |

| 10 | CQ35112 | Porca Fina Hexágono | 1 |

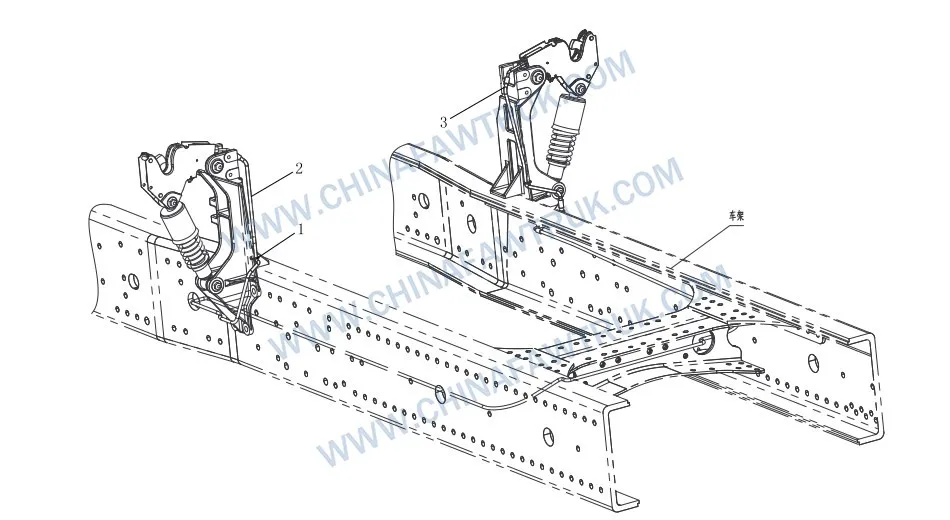

Cab Tilt Control Mechanism3

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | T67410224 | Faixa de plástico | 2 |

| 2 | 5004125-14B-C00 | Conjunto de tubo de óleo – Connecting Left Hydraulic Lock and Tee Joint | 1 |

| 3 | 5004130-14B | Conjunto de tubo de óleo – Connecting Right Hydraulic Lock and Tee Joint | 1 |

The Primary Power Source: Electric Hydraulic Pump

No centro do Mecanismo de controle de inclinação da cabine reside o Conjunto de bomba hidráulica elétrica – Elevador de cabine (Parte não. 5002075AA01-C00). This sophisticated unit serves as the primary driver for raising the heavy steel cabin. In the context of the FAW J6P, the electric pump allows the driver to initiate the tilt sequence with the push of a button, eliminating the physical strain associated with manual pumping. O Mecanismo de controle de inclinação da cabine routes 24V power to a high-torque DC motor within the pump assembly, which pressurizes the hydraulic fluid to over 20 MPa. This pressure is then directed to the tilt cylinders, smoothly lifting the cab to its service position of approximately 60 graus.

O “AA01-C00” specification of the electric pump indicates a unit optimized for cold-weather performance. Standard hydraulic pumps can struggle in the Russian winter as fluid viscosity increases, leading to motor burnout or blown fuses. O Conjunto de bomba hidráulica elétrica – Elevador de cabine incorporated into the Mecanismo de controle de inclinação da cabine features upgraded internal seals and a more powerful motor winding to overcome this viscous drag. Além disso, the pump body includes an integrated reservoir with a specialized breather that prevents moisture ingress, ensuring that the hydraulic fluid remains uncontaminated by melting snow or ice.

Safety logic is built directly into the Mecanismo de controle de inclinação da cabine. O conjunto da bomba elétrica contém válvulas de retenção e restritores de fluxo que evitam que a cabine caia livremente se uma mangueira hidráulica estourar. O Conjunto de bomba hidráulica elétrica – Elevador de cabine também faz interface com o sistema de intertravamento de segurança do caminhão, garantindo que a operação de inclinação só possa começar quando o freio de estacionamento estiver acionado e o seletor de marcha estiver em ponto morto. Essa integração faz com que Mecanismo de controle de inclinação da cabine não apenas uma ferramenta de elevação, mas um sistema de segurança abrangente para o operador do veículo.

O à prova de falhas: Conjunto de bomba manual

Embora a atuação elétrica ofereça conveniência, a dura realidade das operações no Ártico exige redundância. O Mecanismo de controle de inclinação da cabine inclui um dedicado Conjunto de bomba manual – Elevador de cabine (Parte não. 5002070A77C-C00) como um sistema de backup completamente independente. No caso de uma falha elétrica total – um cenário comum depois que um caminhão fica estacionado por dias a -40°C – a bomba manual permite que o motorista ou mecânico eleve a cabine para acessar as baterias e o motor. O Mecanismo de controle de inclinação da cabine garante que o veículo permaneça operacional mesmo quando estiver “frio mortal.”

O Conjunto de bomba manual – Elevador de cabine é projetado com um soquete de braço de alavanca longo para maximizar a vantagem mecânica. Isto permite que um único operador gere a pressão hidráulica necessária sem esforço físico excessivo. A válvula interna da bomba manual dentro do Mecanismo de controle de inclinação da cabine está separado do circuito elétrico, ou seja, uma falha na válvula de retenção da eletrobomba não compromete o funcionamento manual. Este isolamento é uma característica crítica do projeto do Mecanismo de controle de inclinação da cabine, proporcionando um verdadeiro “Plano B” para reparos em campo.

Construído em aço fundido de alta qualidade e tratado com revestimentos anticorrosivos, o Conjunto de bomba manual – Elevador de cabine é construído para resistir à exposição ao sal e sujeira da estrada. Normalmente é montado em um local acessível no chassi, muitas vezes atrás dos degraus da cabine. O Mecanismo de controle de inclinação da cabine O design garante que a folga da alavanca da bomba manual seja suficiente mesmo quando o caminhão estiver equipado com carenagens laterais ou guarda-lamas, garantindo que o acesso nunca seja impedido durante uma emergência.

Montagem de Precisão e Integridade Estrutural

A montagem do Mecanismo de controle de inclinação da cabine componentes ao chassi requer rigidez absoluta. A eletrobomba é fixada por dois Parafuso de combinação fixadores (Parte não. CQ1460820F6). Esses parafusos M8 apresentam um flange integrado e uma face serrilhada que encaixam no suporte de montagem, impedindo-os de recuar sob a vibração de alta frequência do motor diesel. O Mecanismo de controle de inclinação da cabine depende desses parafusos para manter a orientação da bomba, garantindo que o coletor de fluido permaneça submerso no reservatório mesmo quando o caminhão estiver estacionado em uma inclinação íngreme.

De forma similar, a bomba manual é ancorada por M10 mais pesado Parafuso de combinação unidades (Parte não. CQ1461020F6). A bomba manual sofre cargas de torque significativas quando o operador está bombeando a alavanca do punho. O diâmetro maior desses parafusos dentro do Mecanismo de controle de inclinação da cabine fornece a resistência ao cisalhamento necessária para resistir às forças de torção. Se esses parafusos se soltassem, a bomba manual pode mudar, potencialmente dobrando as linhas hidráulicas rígidas conectadas a ele. O Mecanismo de controle de inclinação da cabine engenharia especifica “F6” revestimento resistente à corrosão para todos os fixadores, protegendo os fios de gripagem devido à ferrugem.

As conexões hidráulicas entre o Conjunto de bomba hidráulica elétrica – Elevador de cabine, o Conjunto de bomba manual – Elevador de cabine, e os cilindros de elevação são feitos através de linhas de aço de alta pressão e mangueiras flexíveis. O Mecanismo de controle de inclinação da cabine utiliza acessórios de banjo e arruelas de cobre nas interfaces da bomba para garantir um desempenho livre de vazamentos. Manter a integridade dessas conexões é vital; um único vazamento no Mecanismo de controle de inclinação da cabine pode tornar todo o sistema de inclinação inoperante, prendendo o motor embaixo da cabine.

Manutenção e solução de problemas

A manutenção regular do Mecanismo de controle de inclinação da cabine é essencial para a segurança. O nível de fluido hidráulico no reservatório deve ser verificado durante cada intervalo de manutenção. Níveis baixos de fluido podem causar cavitação de ar no Conjunto de bomba hidráulica elétrica – Elevador de cabine, levando a movimentos bruscos da cabine ou falha da bomba. O pivô da alavanca da bomba manual deve ser lubrificado para garantir um funcionamento suave. Os mecânicos da frota também devem inspecionar o Parafuso de combinação fixadores para aperto, pois a vibração do chassi pode afrouxá-los com o tempo.

Se a inclinação elétrica não funcionar, o primeiro passo diagnóstico para o Mecanismo de controle de inclinação da cabine é verificar o fusível e o relé na caixa de fusíveis do chassi. Se a energia estiver presente, as escovas do motor ou solenóide podem estar desgastadas. Em tais casos, o design modular do Mecanismo de controle de inclinação da cabine permite a substituição do Conjunto de bomba hidráulica elétrica – Elevador de cabine como uma única unidade. A tentativa de reconstruir a bomba no campo geralmente não é recomendada devido à precisão necessária para o conjunto de engrenagens internas.

Testando o Conjunto de bomba manual – Elevador de cabine deve fazer parte da inspeção anual. Ao longo do tempo, as vedações internas da bomba manual podem secar se não forem utilizadas. O ciclo da bomba manual através de uma sequência completa de elevação e descida garante que as vedações permaneçam lubrificadas e que o Mecanismo de controle de inclinação da cabine está pronto para uma emergência. O uso de peças de reposição genuínas da FAW garante que as classificações de pressão e as características de fluxo correspondam ao projeto do sistema, evitando danos aos cilindros de elevação.

Conclusão: Desbloqueando a capacidade de manutenção

O Mecanismo de controle de inclinação da cabine é a porta de entrada para o motor, permitindo todas as principais tarefas de manutenção no veículo. Ao combinar o Conjunto de bomba hidráulica elétrica – Elevador de cabine e o Conjunto de bomba manual – Elevador de cabine em um sistema redundante, FAW garante que o acesso nunca seja negado. O 4 os componentes listados – as duas bombas e seus parafusos de montagem – formam o núcleo deste sistema crítico.

Para gerentes de frota, o Mecanismo de controle de inclinação da cabine representa a garantia de manutenibilidade. Um táxi preso pode transformar um pequeno reparo em uma grande dor de cabeça logística. Ao manter as bombas e conexões hidráulicas, e garantindo que o hardware de montagem esteja seguro, os operadores protegem a sua capacidade de servir a frota de forma eficiente, manter os caminhões funcionando e produtivos no desafiador ambiente russo.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.