الشاحن التربيني الروسي FAW: 17 مكونات دقيقة لقوة قطبية لا مثيل لها

ال الشاحن التربيني الروسي FAW is the forced induction powerhouse of the CA3250P66K24L1TE5Z engine, designed to deliver dense, oxygen-rich air for combustion even in the thinnest, coldest atmospheres. This guide explores the critical lubrication circuits, mounting architecture, and thermal shielding required to maintain boost pressure and reliability in the Russian Federation.

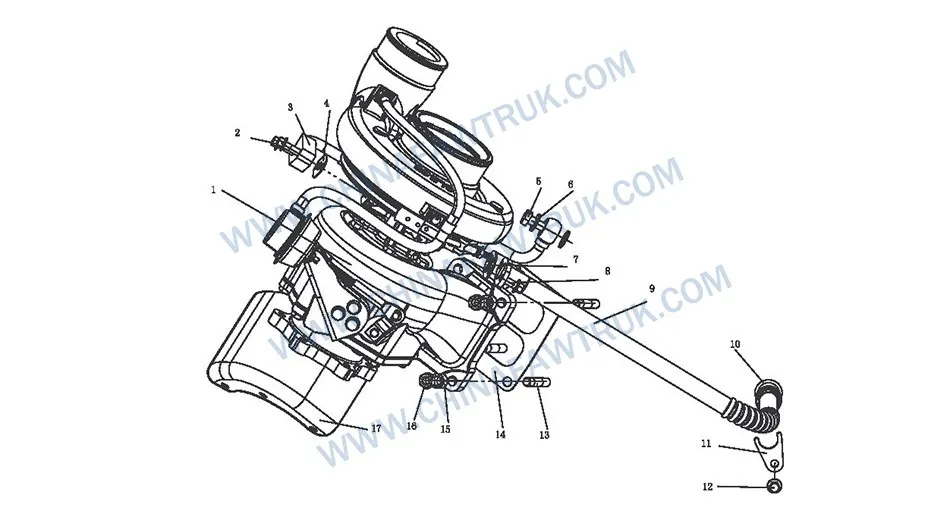

الشاحن التربيني الروسي FAW

الآلية الأساسية: Turbine Engineering and Heat Management

The centerpiece of the forced induction system is the تجميع الشاحن التوربيني (الجزء لا. 1118010-51W-C00). داخل الشاحن التربيني الروسي FAW بنيان, this component must bridge the gap between two thermal extremes: the freezing ambient air entering the compressor and the 700°C exhaust gases driving the turbine. The housing is cast from high-nickel alloys to resist thermal cracking during the rapid heating cycles characteristic of cold starts in Russia.

Maintaining the efficiency of the الشاحن التربيني الروسي FAW requires precise management of radiant heat. ال Turbocharger Heat Shield (الجزء لا. 1118031-51دبليو) is not a cosmetic cover; it is a critical thermal barrier. By containing the infrared radiation emitted by the turbine housing, it protects adjacent rubber hoses and electrical harnesses from melting.

بالإضافة إلى, this shield helps retain heat energy within the turbine housing itself. في الشاحن التربيني الروسي FAW نظام, heat equals energy; keeping the exhaust gases hot ensures they maintain maximum velocity to drive the turbine wheel. This results in faster spool-up times and reduced turbo lag, which is essential for maneuvering heavy dump trucks in deep snow or mud.

High-Pressure Feed: The Lifeblood of the Bearing

The shaft of the الشاحن التربيني الروسي FAW spins at speeds exceeding 100,000 دورة في الدقيقة, floating on a microscopic film of oil. This oil is delivered via the Turbocharger Oil Inlet Pipe Assembly (الجزء لا. 1118060-74أ). This steel pipe is precision-bent to route around the hot exhaust manifold without touching it, preventing oil coking within the line.

The connection to the turbo center housing utilizes a بولت جوفاء (الجزء لا. 1118071-53د), also known as a banjo bolt. This bolt features precisely drilled cross-holes that meter the oil flow. في الشاحن التربيني الروسي FAW تصميم, these holes act as a restrictor to prevent over-pressurizing the bearing seals, which could force oil into the intake or exhaust stream.

Sealing this high-pressure connection relies on two units of the غسالة ختم (الجزء لا. CQ72316). These crush washers, typically made of copper or aluminum, deform during torque application to create a hermetic seal. Reusing these washers is a primary cause of engine fires; a leak here sprays pressurized oil directly onto the hot turbine housing of the الشاحن التربيني الروسي FAW.

At the block interface, ال طوقا – Inlet Flange (الجزء لا. 1118063-D6) ensures a leak-free supply. This gasket must withstand high oil pressure and vibration simultaneously. The integrity of the supply line is non-negotiable; any interruption in oil flow, even for a second, will cause the الشاحن التربيني الروسي FAW bearings to weld themselves to the shaft instantly.

Gravity Drain: Ensuring Free-Flowing Return

After lubricating the bearings, the oil must exit the center housing rapidly via gravity. ال Turbocharger Oil Return Pipe Assembly (الجزء لا. 1118080-74أ) manages this crucial flow. في الشاحن التربيني الروسي FAW نظام, this pipe has a large diameter to prevent oil backup. If the oil cannot drain fast enough, it floods the bearing housing and leaks past the dynamic seals, causing the engine to burn oil and emit blue smoke.

The connection to the turbocharger is secured by the Press Plate – أنبوب عودة زيت الشاحن التوربيني (الجزء لا. 1118083-81د). This heavy steel plate distributes the clamping force of the مسامير شفة سداسية (الجزء لا. س1840816) evenly across the flange. Without this plate, the thin flange of the return pipe would warp, leading to leaks in the الشاحن التربيني الروسي FAW drain system.

Sealing is provided by the طوقا – أنبوب عودة زيت الشاحن التوربيني (الجزء لا. 1118094-29د) at the top and the الهيدروليكية الهوائية O-حلقة مطاطية الختم (الجزء لا. CQ7343236B) where the pipe enters the engine block. This O-ring is formulated from high-temperature Viton to resist hardening. A failed O-ring here allows oil to weep down the side of the block, a common issue in older الشاحن التربيني الروسي FAW installations if maintenance is neglected.

Mounting Stability: ترصيع, الأكمام, and Expansion

The connection between the turbocharger and the exhaust manifold is one of the most stressed joints in the engine. ال الشاحن التربيني الروسي FAW utilizes four Double End Studs (الجزء لا. CQ1201025) for this purpose. Studs are preferred over bolts because they allow for more accurate torque application and are less likely to seize in the manifold casting.

A unique feature of the الشاحن التربيني الروسي FAW mounting system is the use of the كم – الشاحن التوربيني (الجزء لا. 1118014-53د). These spacer sleeves are placed over the studs. They act as thermal buffers, allowing the fastener assembly to expand and contract at a different rate than the cast iron flanges. This elasticity prevents the studs from snapping under the immense thermal stress of a regeneration cycle or a long uphill climb.

The seal between the manifold and the turbo is created by the Turbocharger Gasket (الجزء لا. 1118013A81D). This is a multi-layer steel (متعدد الأطراف) gasket capable of surviving 800°C. Securing the entire stack are the بندق – الشاحن التوربيني (الجزء لا. 1118073-29د) وحدات. These are typically copper-plated or made of a specific alloy to prevent galling, ضمان الشاحن التربيني الروسي FAW can be serviced in the future without cutting the nuts off.

قائمة تفصيل المكونات

يسرد الجدول التالي المكونات المحددة التي تتألف منها الشاحن التربيني الروسي FAW منطق. Fleet managers must use these exact part numbers to ensure the flow rates, thermal tolerances, and fitment match the CA3250P66K24L1TE5Z specification.

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 |

1118010-51W-C00 |

تجميع الشاحن التوربيني (نمط) |

1 |

| 2 |

س1840830 |

سداسية شفة الترباس (عرقوب خشن/قياسي) |

2 |

| 3 |

1118060-74أ |

Turbocharger Oil Inlet Pipe Assembly |

1 |

| 4 |

1118063-D6 |

طوقا – Inlet Flange |

1 |

| 5 |

1118071-53د |

بولت جوفاء (Banjo Bolt) |

1 |

| 6 |

CQ72316 |

غسالة ختم |

2 |

| 7 |

1118094-29د |

طوقا – أنبوب عودة زيت الشاحن التوربيني |

1 |

| 8 |

س1840816 |

سداسية شفة الترباس (عرقوب خشن/قياسي) |

2 |

| 9 |

1118080-74أ |

Turbocharger Oil Return Pipe Assembly |

1 |

| 10 |

CQ7343236B |

الهيدروليكية الهوائية O-حلقة مطاطية الختم |

1 |

| 11 |

1118083-81د |

Press Plate – أنبوب عودة زيت الشاحن التوربيني |

1 |

| 12 |

س1840812 |

سداسية شفة الترباس (عرقوب خشن/قياسي) |

1 |

| 13 |

CQ1201025 |

مسمار نهاية مزدوجة |

4 |

| 14 |

1118013A81D |

Turbocharger Gasket |

1 |

| 15 |

1118014-53د |

كم – الشاحن التوربيني |

4 |

| 16 |

1118073-29د |

بندق – الشاحن التوربيني |

4 |

| 17 |

1118031-51دبليو |

Turbocharger Heat Shield |

1 |

Diagnostic Protocols for Boost Health

فحص الشاحن التربيني الروسي FAW starts with visual checks of the lubrication lines. Oil wetness around the بولت جوفاء or the return pipe flange indicates a compromised seal. في الشتاء الروسي, these leaks often appear after the engine cools down and components contract. Addressing these leaks immediately is vital to prevent oil starvation or fire.

Auditory diagnostics can reveal internal issues. A high-pitched whine that varies with engine load suggests bearing wear or compressor blade damage. This often results from restricted oil flow through the Turbocharger Oil Inlet Pipe Assembly. Regularly checking the oil feed line for sludge buildup is a proactive measure that can save the turbo.

أخيراً, verify the integrity of the mounting hardware. Loose Double End Studs or nuts can cause exhaust leaks between the manifold and turbo. This reduces boost pressure, leading to low power and black smoke. إذا Turbocharger Gasket has blown out, it must be replaced along with new locking nuts to restore the system’s efficiency.

خاتمة: Power and Reliability

ال الشاحن التربيني الروسي FAW is a precision instrument essential for the performance of the CA3250P66K24L1TE5Z dump truck. It provides the air density needed for efficient combustion in harsh environments. كل مكون, from the thermal كم to the oil-control Banjo Bolt, is engineered to withstand the unique stresses of Arctic operation.

لأصحاب الأسطول, maintaining this assembly with genuine parts is the key to maximizing uptime. Generic turbos or seals often fail to meet the material specifications required for extreme temperature cycling. من خلال الاستثمار في الأصيل الشاحن التربيني الروسي FAW النظام البيئي, you ensure that your fleet retains its power, كفاءة, and reliability on the toughest roads in the world.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.