Gas-Heated Independent Heating System: Mastering 14 Strategic Components for Zero-Idling Arctic Thermal Assurance

The Gas-Heated Independent Heating System is a mission-critical auxiliary thermal unit for the FAW CA3250P66K24L1TE5Z dump truck, ensuring thermal readiness without engine idling. Designed specifically for the Russian Arctic, this air-heating system draws fuel to provide instant, dry heat to the cab and defrost the windshield. The Gas-Heated Independent Heating System dramatically reduces fuel consumption during rest periods and guarantees a safe, warm environment for the operator, fulfilling essential safety and operational requirements in temperatures well below freezing.

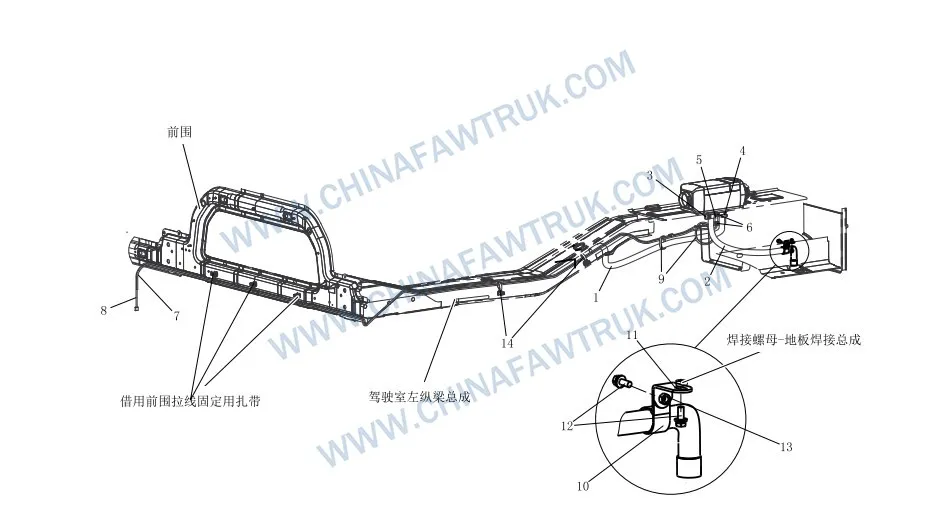

Gas-Heated Independent Heating System (For The Entire Vehicle)

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8115570-13A |

Oil Extraction Head Assembly |

1 |

| 2 |

8115596-B82 |

Standard Soft Connection |

3 |

| 3 |

8115595-B82 |

Clamp |

7 |

| 4 |

8115580-81U |

Oil Pump Assembly |

1 |

| 5 |

8115585-81U |

Oil Pump Fixing Bracket Assembly |

1 |

| 6 |

8115640-72C |

Oil Pump Wiring Harness Assembly – Vehicle |

1 |

| 7 |

8115562-72C |

Fuel Pipe B |

1 |

| 8 |

CQ1460835 |

Combination Bolt |

1 |

| 9 |

Q40208 |

Large Washer |

1 |

| 10 |

CQ34008 |

Hexagon Nut |

1 |

| 11 |

T67427946 |

Plastic Band |

6 |

| 12 |

8115561-13A |

Fuel Pipe A |

1 |

| 13 |

8115596-13A |

Special Soft Connection |

1 |

| 14 |

8115595-13A |

Clamp – Special Soft Connection |

1 |

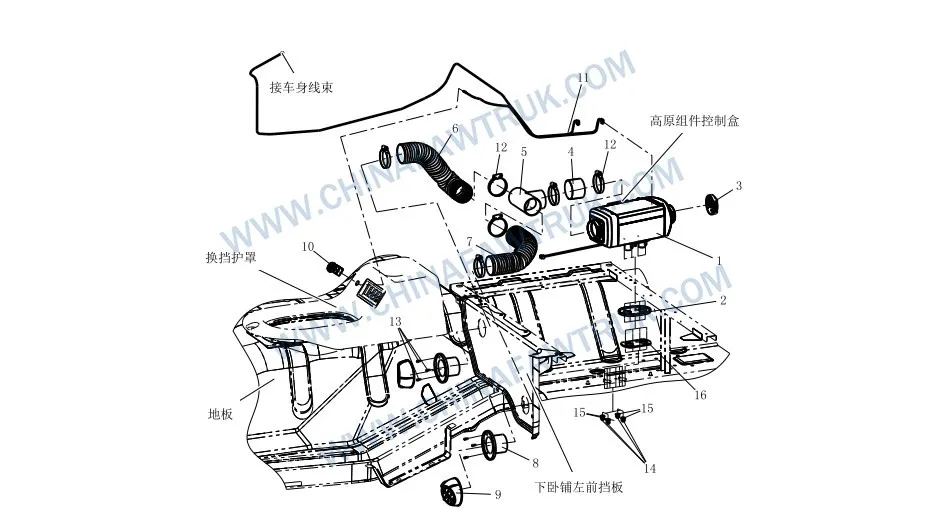

Gas-Heated Independent Heating System (Cab)

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8115631-B82 |

Intake Pipe |

1 |

| 2 |

8115621AB96 |

Exhaust Pipe |

1 |

| 3 |

8115625-B82 |

Exhaust Pipe Fixing Clamp Assembly |

1 |

| 4 |

CQ67630B |

Hose Clip B Type with Worm Drive |

5 |

| 5 |

8115596-B82 |

Standard Soft Connection |

1 |

| 6 |

8115595-B82 |

Clamp |

2 |

| 7 |

8115561-B82 |

Fuel Pipe |

1 |

| 8 |

8115645-B82 |

Oil/Fuel Pipe Wiring Harness Assembly – Cab |

1 |

| 9 |

T67427946 |

Plastic Band |

2 |

| 10 |

8115627-B82 |

Exhaust Pipe Clip |

1 |

| 11 |

8115656-B82 |

Bracket |

1 |

| 12 |

CQ1460616 |

Combination Bolt |

2 |

| 13 |

CQ34006 |

Hexagon Nut |

5 |

| 14 |

3724012-A01 |

Cable Tie II |

2 |

Gas-Heated Independent Heating System (Cab)2

| No. |

Part Number |

Part Name |

Qty |

| 1 |

8115505-D04 |

Highland Heater Assembly |

1 |

| 2 |

8115551-B82 |

Sealing Gasket |

1 |

| 3 |

8115552-B82 |

Intake Port Protection Cover |

1 |

| 4 |

8115601AB96 |

Heat Resistant Pipe A |

1 |

| 5 |

8115604-B82 |

T-Shaped Three-Way Connector |

1 |

| 6 |

8115602AB96 |

Heat Resistant Pipe B |

1 |

| 7 |

8115603AB96 |

Heat Resistant Pipe C |

1 |

| 8 |

8115611-B82 |

Air Outlet Base |

2 |

| 9 |

8115612-B82 |

Air Outlet Grille |

1 |

| 10 |

8115650-B82 |

Temperature Control Switch Assembly |

1 |

| 11 |

8115640-D04 |

Heater Main Line Harness Assembly |

1 |

| 12 |

CQ67670B |

Hose Clip B Type with Worm Drive |

6 |

| 13 |

CQ2713513 |

Cross Recessed Pan Head Self-Tapping Screw |

6 |

| 14 |

CQ34006 |

Hexagon Nut |

5 |

| 15 |

Q40106 |

Washer |

4 |

| 16 |

8115551AB96 |

Sealing Gasket |

1 |

Combustion and Air Management Cores

The functionality of the Gas-Heated Independent Heating System hinges on the management of air and exhaust gases. The Intake Pipe (Part No. 8115631-B82) draws fresh, oxygen-rich air into the burner’s combustion chamber. This air must be clean to ensure efficient, soot-free combustion, vital for the long-term health of the heat exchanger core. The rigid structure of the Intake Pipe prevents collapse under vacuum or strong crosswinds, guaranteeing the Gas-Heated Independent Heating System has a constant supply of air.

Combustion products are safely expelled via the Exhaust Pipe (Part No. 8115621AB96). This pipe must be completely leak-proof to prevent toxic fumes from entering the cab or interfering with the clean heat exchange process. The material of the Exhaust Pipe is high-grade stainless steel or aluminum, selected for its resistance to high temperatures and the corrosive, acidic condensation common in exhaust lines. This safety feature is critical for the Gas-Heated Independent Heating System, ensuring driver safety during long rest periods when the main engine is off.

Securing the exhaust line is the Exhaust Pipe Fixing Clamp Assembly (Part No. 8115625-B82). This clamp provides a rigid, vibration-resistant mount for the pipe, preventing it from rattling against the chassis. Further protection is offered by the Exhaust Pipe Clip (Part No. 8115627-B82), which ensures proper routing and thermal spacing. The correct mounting of the Exhaust Pipe is essential for maintaining the heat separation required for the safe and quiet operation of the Gas-Heated Independent Heating System.

Fuel and Electrical Interface Integrity

The connection between the main fuel system and the heater unit is managed by the Standard Soft Connection (Part No. 8115596-B82). This flexible polymer component isolates the heater assembly from the severe chassis vibration of the CA3250 dump truck. Without this soft connection, the rigid fuel line components would quickly fatigue and leak. The Standard Soft Connection is secured by the Clamp (Part No. 8115595-B82), which provides the necessary radial compression to ensure a leak-proof seal under constant pressure and vibration.

The fuel lines themselves, such as the Fuel Pipe (Part No. 8115561-B82), must be chemically resistant to diesel fuel and structurally robust against cold cracking. This Fuel Pipe material specification ensures flexibility at sub-zero temperatures. Electrical power and control signals are transmitted via the Oil/Fuel Pipe Wiring Harness Assembly – Cab (Part No. 8115645-B82). This harness features specialized insulation that is highly resistant to both abrasion and cold cracking, protecting the electrical connections of the Gas-Heated Independent Heating System.

The secure routing of the harness and fuel lines is critical, utilizing the Plastic Band (Part No. T67427946) and Cable Tie II (Part No. 3724012-A01) to anchor the wires away from heat sources and sharp edges. This prevents chafing, which could lead to a dangerous short circuit or fuel leak, preserving the operational integrity of the Gas-Heated Independent Heating System. The integrity of this harness is paramount; a short circuit could disable the heater in life-threatening temperatures.

Mounting Hardware and Clamp Security

The structural mounting of the heater is provided by the Bracket (Part No. 8115656-B82). This component ensures the burner remains correctly oriented and stable during operation. The Bracket is secured with specialized fasteners like the Combination Bolt (Part No. CQ1460616), which features an anti-vibration locking mechanism to maintain the mounting rigidity. This is a necessity for the safe and precise operation of the Gas-Heated Independent Heating System burner and blower fan.

The numerous connection points require robust clamping, utilizing the Hose Clip B Type with Worm Drive (Part No. CQ67630B). These clips provide continuous, adjustable radial compression, which is crucial for forming an airtight seal on the flexible components and preventing detachment during temperature extremes. The worm drive design allows for precision tightening without cutting into the pipe material, preserving its longevity and the reliability of the Gas-Heated Independent Heating System.

The mounting hardware includes the Hexagon Nut (Part No. CQ34006), which is corrosion-resistant. This is vital as the heater is mounted in the lower chassis areas exposed to road salts and moisture. The resistance of the Hexagon Nut and Combination Bolt to seizing ensures that the Bracket and other components can be easily removed and serviced, maintaining the crucial efficiency of the Gas-Heated Independent Heating System throughout the CA3250 dump truck’s service life.

Maintenance and System Reliability

Maintenance of the Gas-Heated Independent Heating System involves checking the integrity of the exhaust and fuel lines. The Exhaust Pipe Clip should be inspected for signs of loosening, which can indicate excessive vibration. The Fuel Pipe and the harness must be checked regularly for abrasion, especially near the mounting points secured by the Plastic Band. Immediate replacement of a damaged Standard Soft Connection is required to prevent diesel leaks and ensure safety, as this is a common wear point for the Gas-Heated Independent Heating System.

The Intake Pipe must be checked for blockage, especially after driving through deep snow or mud. A clogged intake restricts the air required for combustion, leading to inefficient burning and excessive carbon buildup in the heater core. Maintaining the cleanliness of the Intake Pipe and the structural integrity of the Exhaust Pipe is crucial for maximizing the heater’s efficiency and minimizing toxic emissions. The use of the specific Hose Clip B Type with Worm Drive is also vital for ensuring an effective seal.

The components, such as the Exhaust Pipe Fixing Clamp Assembly and the Bracket, provide rigid anchors. Utilizing only genuine fasteners, such as the Combination Bolt and Hexagon Nut, ensures that this auxiliary system remains a reliable safety and cost-saving asset in the highly challenging operating environment of the Russian Arctic. This attention to detail ensures the Gas-Heated Independent Heating System performs its intended function flawlessly.

Conclusion: Guaranteed Thermal Readiness

The Gas-Heated Independent Heating System is a non-negotiable safety feature for the FAW CA3250 dump truck. Its meticulous engineering ensures reliable performance in extreme cold. By integrating the high-temperature Exhaust Pipe with the protective Oil/Fuel Pipe Wiring Harness Assembly – Cab, FAW guarantees continuous thermal readiness. The Standard Soft Connection and the Exhaust Pipe Fixing Clamp Assembly maintain the integrity of the fuel and exhaust circuits, preventing failure.

This system, anchored by the Bracket and secured by corrosion-resistant hardware, ensures that the driver can always return to a warm cab and start a preheated engine. Adhering to the specified components and maintenance protocols ensures the Gas-Heated Independent Heating System continues to deliver efficiency and safety, allowing operations to proceed smoothly in the harshest environments the Russian North can offer. The secure routing using the Plastic Band and Cable Tie II is critical for long-term reliability.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.