FAW Russian Rear-Spring Stop Bracket: Reinforcing 7 Strategic Points for Suspension Travel Control

The FAW Russian Rear-Spring Stop Bracket logic assembly acts as the definitive travel limiter for the rear suspension of the CA3250P66K24L1TE5Z dump truck. Positioned to intercept excessive compression loads, this assembly prevents metal-on-metal contact between the frame and the axle housing. Engineered for the sub-zero environment of the Siberian mining sector, it utilizes specialized cushioning materials and high-tensile fasteners to absorb kinetic energy without fracturing. This guide details the bracket architecture, the impact damping cushion, and the SPL fastening technology that defines this critical safety stop.

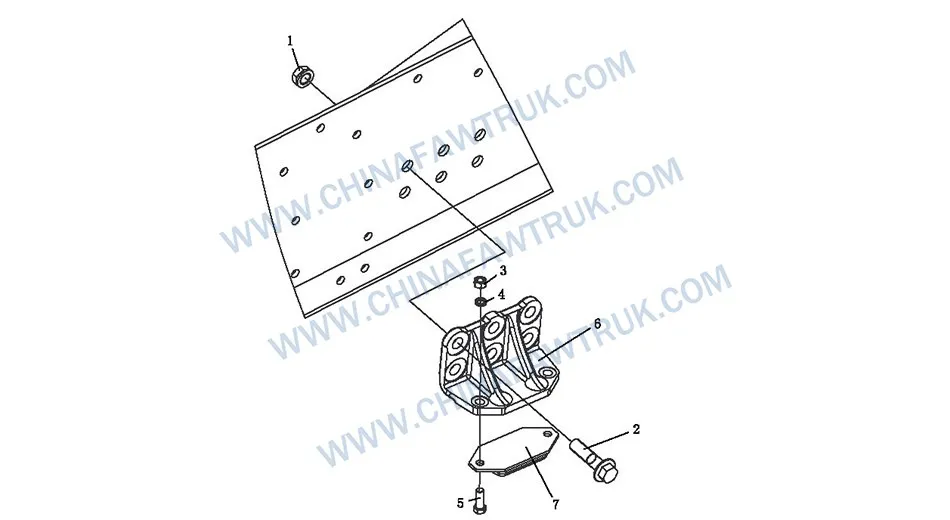

FAW Russian Rear-Spring Stop Bracket

Limit Bracket Structural Dynamics

The primary structural component of this assembly is the Limit Bracket – Buffer Block (Part No. 2912437-64W). This heavy-duty steel bracket acts as the rigid interface between the dynamic suspension system and the static chassis frame. In the FAW Russian Rear-Spring Stop Bracket configuration, this component is subjected to immense compressive forces whenever the truck hits a bump large enough to bottom out the suspension. The “64W” specification implies a reinforced web design capable of withstanding these repetitive impact loads without deforming or cracking.

The geometry of the FAW Russian Rear-Spring Stop Bracket is calculated to define the maximum upward travel of the rear axle. By limiting this travel, the bracket protects the chassis frame rails from being struck by the axle housing, which could cause structural buckling. Furthermore, it prevents the leaf springs from being inverted or over-stressed beyond their elastic limit. This mechanical stop is the final line of defense for the suspension system, ensuring that even under overload conditions, the physical limits of the drivetrain geometry are not exceeded.

Surface protection is critical for the FAW Russian Rear-Spring Stop Bracket. Located in the direct spray path of the rear tires, it is constantly bombarded by gravel, mud, and corrosive de-icing salts. The bracket undergoes a specialized coating process to prevent rust. If corrosion were to compromise the mounting flanges, the entire assembly could detach during a high-impact event, leaving the chassis vulnerable. Therefore, the structural integrity of the FAW Russian Rear-Spring Stop Bracket is maintained through robust material selection and advanced surface treatments.

The bracket also serves as the mounting platform for the rubber cushion. The precision of the mounting holes ensures that the cushion remains centered directly over the axle contact patch. Misalignment in the FAW Russian Rear-Spring Stop Bracket would cause the axle to strike the bracket off-center, leading to shear forces that could snap the mounting bolts. FAW’s engineering precision ensures that the load path remains purely vertical, maximizing the lifespan of the assembly.

Impact Cushioning Technology

Attached to the steel bracket is the Rear Leaf Spring Cushion (Part No. 2912434-65B). This component is the physical buffer that makes contact with the axle. In the context of the FAW Russian Rear-Spring Stop Bracket system, this cushion performs a dual role: it softens the final stage of suspension compression and reduces the noise and vibration transmitted to the chassis. A metal-on-metal stop would send a jarring shockwave through the truck; the cushion absorbs this energy, improving driver comfort and protecting onboard electronics.

The material composition of the cushion is tailored for the Russian Arctic. Standard rubber compounds become hard and brittle at -40°C, often shattering upon impact. The FAW Russian Rear-Spring Stop Bracket cushion utilizes a specialized synthetic elastomer that remains flexible in extreme cold. This ensures that the damping properties are preserved even in the depths of winter. The “65B” designation likely refers to the durometer (hardness) rating and the low-temperature formulation of the material.

Securing the cushion to the bracket is achieved using the Hex Head Bolt (Part No. CQ1501235) paired with the Hex Nut (Part No. CQ34012) and Spring Washer (Part No. Q40312). This fastening set allows the cushion to be replaced independently of the bracket. In the FAW Russian Rear-Spring Stop Bracket assembly, the cushion is considered a sacrificial wear item. Over time, repeated impacts will compress and degrade the material. The bolted design facilitates quick field replacement, ensuring the protection system remains effective.

The spring washer plays a vital role in this sub-assembly. As the cushion compresses, the bolt tension can fluctuate. The Spring Washer (Part No. Q40312) maintains a constant preload on the nut, preventing it from vibrating loose. If the cushion were to fall off, the FAW Russian Rear-Spring Stop Bracket would essentially become a hammer anvil, striking the axle directly and causing severe damage to both components.

SPL Fastening and Chassis Integration

The attachment of the entire FAW Russian Rear-Spring Stop Bracket to the chassis frame rail is secured by a high-tech fastening system. Six Hexagon Head Convex Bolts (Part No. Q1852075T) pass through the frame web. These high-tensile flange bolts are designed to withstand the immense shear forces generated when the suspension bottoms out. The convex head design provides a smooth profile, reducing the accumulation of mud and ice around the fastener.

On the reverse side, the system utilizes the SPL Hex Small Flange Anti-loose Nut (Part No. T32720TF2). The SPL (Self-Prevailing Lock) nut represents a significant upgrade over standard locking nuts. It features a specialized thread deformation or metal interference fit that locks it securely to the bolt thread. In the high-vibration environment of a dump truck, where thermal cycles expand and contract the bolted joints, the SPL nut ensures that the FAW Russian Rear-Spring Stop Bracket never works loose.

The use of flange bolts and flange nuts eliminates the need for separate washers, creating a more reliable, unified clamping interface. The wide flange face distributes the load over a larger area of the chassis rail, preventing the fastener from digging into the steel. This is particularly important for the FAW Russian Rear-Spring Stop Bracket, as maintaining the clamping force is essential to prevent fretting corrosion between the bracket and the frame.

Fleet mechanics should note that SPL nuts are designed for maximum security and are often recommended for single use. When removing the FAW Russian Rear-Spring Stop Bracket for chassis repairs, installing new T32720TF2 nuts is the best practice. This guarantees that the locking feature is at 100% effectiveness, securing the suspension stop against the brutal forces of the road.

Inspection and Replacement Strategy

Regular inspection of the FAW Russian Rear-Spring Stop Bracket is a key part of the vehicle’s preventative maintenance schedule. The primary focus should be on the condition of the Rear Leaf Spring Cushion (Part No. 2912434-65B). If the rubber is cracked, missing chunks, or worn down to the metal backing, it must be replaced immediately. A missing cushion allows the FAW Russian Rear-Spring Stop Bracket to hammer against the axle, leading to stress fractures in the axle housing or the bracket itself.

The mounting bolts (Part No. Q1852075T) should be checked for tightness. Any sign of rust streaking around the bolt heads suggests movement and requires immediate re-torquing. In the FAW Russian Rear-Spring Stop Bracket assembly, loose bolts can elongate the frame holes, turning a simple bolt replacement into a major frame repair. Ensuring these fasteners are tight preserves the structural integrity of the chassis.

When sourcing replacement parts, it is vital to use genuine FAW components. The “64W” bracket and “65B” cushion are specifically formulated for the load and temperature profiles of the CA3250P66K24L1TE5Z. Generic rubber bumpers may freeze and shatter in the Russian winter, rendering the FAW Russian Rear-Spring Stop Bracket ineffective. Genuine parts ensure that the suspension travel limits are maintained exactly as the engineers intended.

By maintaining the FAW Russian Rear-Spring Stop Bracket, operators protect the expensive rear axle and leaf springs from overload damage. It is a small investment in inspection time that pays large dividends in vehicle longevity and reliability in the harshest working conditions.

Component Breakdown: Rear Spring Limit Bracket Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | T32720TF2 | SPL Hex Small Flange Anti-loose Nut | 6 |

| 2 | Q1852075T | Hexagon Head Convex Bolt | 6 |

| 3 | CQ34012 | Hex Nut | 2 |

| 4 | Q40312 | Spring Washer | 2 |

| 5 | CQ1501235 | Hex Head Bolt | 2 |

| 6 | 2912437-64W | Limit Bracket – Buffer Block | 1 |

| 7 | 2912434-65B | Rear Leaf Spring Cushion | 1 |

Conclusion: Protecting Suspension Limits

The FAW Russian Rear-Spring Stop Bracket assembly is the definitive travel limiter that safeguards the entire rear suspension architecture. By providing a cushioned, rigid stop for the axle, it prevents over-compression damage to the chassis and leaf springs. The integration of advanced SPL fastening technology with arctic-grade rubber compounds ensures that this safety device remains effective in the most demanding conditions.

For fleet managers, the FAW Russian Rear-Spring Stop Bracket is a simple yet vital component. Keeping the cushions fresh and the bolts tight is an easy way to prevent major structural failures. Utilizing genuine FAW parts ensures that the specific engineering requirements of the CA3250P66K24L1TE5Z are met, keeping the truck productive and safe on the frozen roads of the north.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.