FAW Russian Rear Leaf Spring: Engineering 20 Critical Components for Arctic Load Dominance

The FAW Russian Rear Leaf Spring assembly constitutes the primary load-bearing suspension architecture for the rear tandem bogie of the CA3250P66K24L1TE5Z dump truck. Designed to support payloads exceeding 30 tons in the unforgiving terrain of the Siberian North, this multi-leaf stack utilizes a sophisticated “55R” low-temperature alloy. The system provides the essential balance between vertical load support and torsional flexibility required to navigate frozen, uneven haul roads. This technical guide breaks down the 13-leaf graduated stack, the heavy-duty clamping system, and the structural cover plate logic that defines this suspension unit.

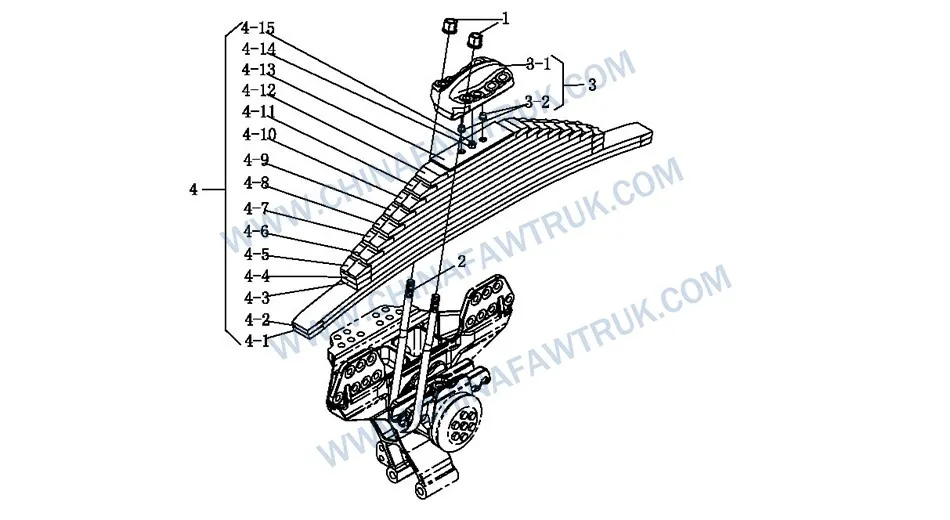

FAW Russian Rear Leaf Spring

The 13-Leaf Stack: Metallurgical Architecture

The foundation of the suspension is the Rear Leaf Spring Assembly (Part No. 2912010-55R). This massive component is comprised of thirteen individual steel leaves, graduated in length to create a progressive spring rate. The stack begins with the master leaves: the Rear Leaf Spring 1st Leaf (Part No. 2912201-55R) and the Rear Leaf Spring 2nd Leaf (Part No. 2912202-55R). These top leaves bear the primary tensile stress during suspension articulation. The “55R” suffix denotes a specialized silicon-manganese steel alloy, heat-treated to maximize fatigue resistance and ductility at -50°C. In standard springs, extreme cold can cause brittle fractures under shock loads; the FAW Russian Rear Leaf Spring is chemically formulated to remain elastic, absorbing the kinetic energy of the road without snapping.

As the load increases, the shorter leaves lower in the stack engage, stiffening the suspension to support the weight. From the Rear Leaf Spring 3rd Leaf (Part No. 2912203-55R) down to the Rear Leaf Spring 13th Leaf (Part No. 2912216-55R), each plate acts as a support beam for the one above it. This parabolic design allows the FAW Russian Rear Leaf Spring to provide a relatively compliant ride when the truck is empty, reducing driver fatigue, while offering immense load-carrying capacity when fully laden. The inter-leaf friction, or hysteresis, provides a natural damping effect that stabilizes the chassis during cornering.

The alignment of this massive stack is maintained by the Center Bolt – Rear Leaf Spring (Part No. 2912161-483). This high-tensile bolt passes through the center of all thirteen leaves, clamping them together. It serves a dual purpose: it keeps the leaves from fanning out during rebound, and its head acts as a locating dowel that indexes into the axle housing. If the FAW Russian Rear Leaf Spring center bolt were to shear, the axle could shift relative to the suspension, causing severe misalignment and “dog-tracking” of the vehicle.

Securing the center bolt is the Hex Nut (Part No. CQ34116T). While small, this nut maintains the preload on the center of the pack. In the vibration-heavy environment of a mining site, checking the tightness of this nut is often overlooked but critical. A loose center pack allows for microscopic movement between the leaves of the FAW Russian Rear Leaf Spring, leading to fret corrosion and eventual leaf breakage at the center hole, the point of highest stress concentration.

High-Tension Clamping System

The attachment of the FAW Russian Rear Leaf Spring to the trunnion axle seat is managed by four massive U-bolt – Fastening Rear Leaf Spring (Part No. 2912411-64W). These U-bolts are the most critical fasteners in the rear suspension. Manufactured from high-yield alloy steel, they are designed to be torqued to yield, stretching slightly to provide a permanent clamping force. This force “welds” the spring pack to the axle seat through friction. The “64W” specification suggests a widened profile or enhanced thread pitch designed to withstand the shear forces generated by a 6×6 drivetrain fighting for traction on ice.

Securing these U-bolts are eight Nut – Fastening U-bolt (Part No. 2912413-56B). These are deep-profile nuts, often heat-treated to Grade 10 or 12, capable of holding the immense tension required. In the FAW Russian Rear Leaf Spring system, the torque on these nuts must be maintained precisely. If they loosen even slightly, the friction grip between the spring and axle is lost. The cyclic loading of the suspension will then hammer the center bolt until it shears, leading to catastrophic suspension failure.

The clamping system must also accommodate thermal contraction. In the -50°C Russian winter, the steel of the U-bolts contracts, potentially increasing tension, while the cast iron axle housing may contract at a different rate. The FAW Russian Rear Leaf Spring fasteners are engineered with specific elasticity to maintain clamping load across this thermal spectrum. Regular re-torquing of these U-bolts is the single most effective preventative maintenance task for the rear suspension.

This high-tension clamping logic ensures that the FAW Russian Rear Leaf Spring acts as a unified structural member with the axle. It prevents the “shuffling” of leaves which can wear down the center bolt. The robust design of the 2912411-64W U-bolts allows the truck to carry full payloads over washboard roads without the suspension dismantling itself, a testament to the heavy-duty engineering behind the FAW J6P platform.

Cover Plate and Locating Logic

Sitting atop the leaf stack is the Rear Leaf Spring Cover Plate with Locating Pin Assy (Part No. 2912410-55R). This component distributes the crushing force of the U-bolts evenly across the top leaf, preventing stress risers that could crack the steel. It consists of the main Cover Plate – Rear Leaf Spring (Part No. 2912406-64W) and integrated locating elements. The cover plate is a heavy casting, ribbed for stiffness to resist bending under the U-bolt load.

Crucial to the assembly are the two Locating Pin (Part No. 2912403-55R). These pins ensure the precise alignment of the cover plate relative to the spring pack and the trunnion seat. In the FAW Russian Rear Leaf Spring system, alignment is paramount. If the spring pack is mounted slightly askew, the rear axles will not be parallel, leading to severe tire scrubbing and unpredictable handling. The locating pins act as the geometric reference for the entire rear bogie installation.

The interface between the cover plate and the top leaf is a critical friction zone. The FAW Russian Rear Leaf Spring design ensures that this contact area is maximized. Any gap or debris here can lead to point loading. During assembly, it is vital that the surfaces are clean. The “55R” specification of the pins ensures they have the shear strength to resist the lateral forces generated when the truck turns, keeping the entire stack square and secure.

Furthermore, the cover plate provides the mounting surface for the rebound clips or stops (depending on chassis configuration). By integrating these functions into a single robust casting, the FAW Russian Rear Leaf Spring logic simplifies the suspension architecture while increasing its durability. The cover plate acts as the “capstone” of the leaf spring pyramid, locking the kinetic potential of the steel leaves into a usable suspension system.

Maintenance and Arctic Serviceability

The service life of the FAW Russian Rear Leaf Spring is directly tied to maintenance discipline. In the Russian Arctic, mud and ice can pack between the leaves, causing rust jacking. This expansion of rust forces the leaves apart, increasing stress on the U-bolts and center bolt. Regular high-pressure washing and visual inspection for “fanning” (leaves splaying out) is essential. If fanning is observed, it indicates that the U-bolts have lost tension or the clamps have failed.

When replacing individual leaves, such as the Rear Leaf Spring 4th Leaf (Part No. 2912204-55R) or Rear Leaf Spring 5th Leaf (Part No. 2912206-55R), it is imperative to use genuine FAW parts. The curvature (camber) of each leaf must match perfectly. Mixing aftermarket leaves with different spring rates will create internal stress within the pack, leading to rapid failure of the new components. The FAW Russian Rear Leaf Spring functions as a tuned system; disrupting this harmony invites disaster.

Re-torquing the U-bolt nuts (Part No. 2912413-56B) should be performed with the vehicle loaded, if possible, to ensure the pack is fully compressed. The threads should be cleaned and lubricated to ensure the torque reading reflects actual clamping force, not friction. Neglecting the FAW Russian Rear Leaf Spring fasteners is the leading cause of suspension downtime in heavy-duty fleets.

Component Breakdown: Rear Leaf Spring Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | 2912413-56B | Nut – Fastening U-bolt | 8 |

| 2 | 2912411-64W | U-bolt – Fastening Rear Leaf Spring | 4 |

| 3 | 2912410-55R | Rear Leaf Spring Cover Plate with Locating Pin Assy | 1 |

| 3-1 | 2912406-64W | Cover Plate – Rear Leaf Spring | 1 |

| 3-2 | 2912403-55R | Locating Pin | 2 |

| 4 | 2912010-55R | Rear Leaf Spring Assembly | 1 |

| 4-1 | 2912201-55R | Rear Leaf Spring 1st Leaf | 1 |

| 4-2 | 2912202-55R | Rear Leaf Spring 2nd Leaf | 1 |

| 4-3 | 2912203-55R | Rear Leaf Spring 3rd Leaf | 1 |

| 4-4 | 2912204-55R | Rear Leaf Spring 4th Leaf | 1 |

| 4-5 | 2912206-55R | Rear Leaf Spring 5th Leaf | 1 |

| 4-6 | 2912207-55R | Rear Leaf Spring 6th Leaf | 1 |

| 4-7 | 2912208-55R | Rear Leaf Spring 7th Leaf | 1 |

| 4-8 | 2912209-55R | Rear Leaf Spring 8th Leaf | 1 |

| 4-9 | 2912211-55R | Rear Leaf Spring 9th Leaf | 1 |

| 4-10 | 2912212-55R | Rear Leaf Spring 10th Leaf | 1 |

| 4-11 | 2912213-55R | Rear Leaf Spring 11th Leaf | 1 |

| 4-12 | 2912214-55R | Rear Leaf Spring 12th Leaf | 1 |

| 4-13 | 2912216-55R | Rear Leaf Spring 13th Leaf | 1 |

| 4-14 | CQ34116T | Hex Nut | 1 |

| 4-15 | 2912161-483 | Center Bolt – Rear Leaf Spring | 1 |

Conclusion: The Backbone of Logistics

The FAW Russian Rear Leaf Spring is the unsung hero of the CA3250P66K24L1TE5Z dump truck’s capabilities. It manages the enormous dynamic loads of mining operations while ensuring stability and safety in extreme cold. By integrating 13 layers of specialized alloy steel with a robust clamping architecture, FAW has created a suspension system that thrives where others fracture.

For fleet operators, the maintenance of this system—specifically the U-bolts and center bolt—is the key to longevity. Using genuine FAW parts for replacement guarantees that the metallurgical properties and dimensional precision of the FAW Russian Rear Leaf Spring are preserved, ensuring the vehicle continues to deliver reliable performance in the harshest environments on Earth.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.