FAW Russian Catalytic Reduction Aftertreatment: Mastering 15 Critical Components for Flawless Arctic Performance

The FAW Russian Catalytic Reduction Aftertreatment logic assembly serves as the advanced chemical processing plant for the CA3250P66K24L1TE5Z dump truck. Designed to operate in the brutal extremes of the Siberian winter, this system manages the reduction of nitrogen oxides (NOx) into harmless nitrogen and water vapor. This guide analyzes the 15 critical components of the FAW Russian Catalytic Reduction Aftertreatment system, dissecting the engineering behind its ceramic substrates, thermal expansion straps, and high-tensile mounting hardware that ensures Euro 5/6 compliance at -40°C.

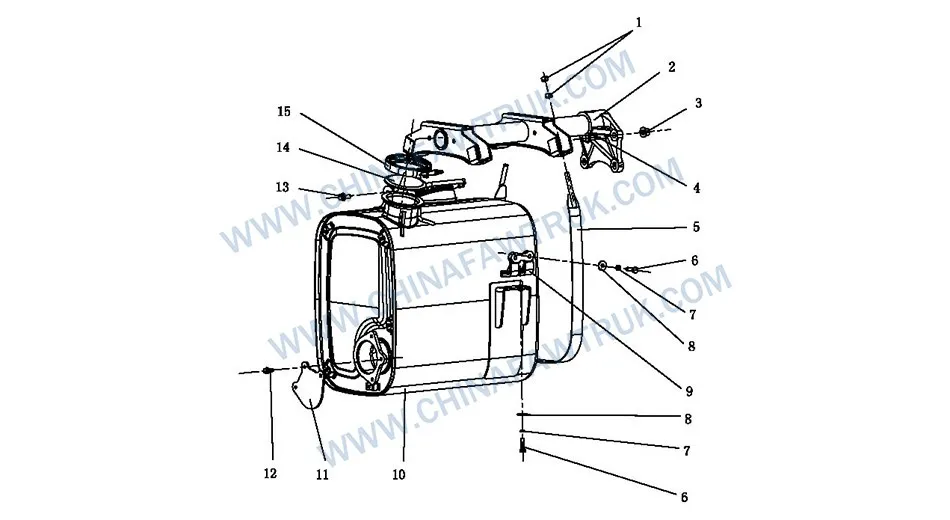

FAW Russian Catalytic Reduction Aftertreatment

The Reactor Core: Selective Catalytic Reduction Assembly

The central component is the Selective Catalytic Reduction After-Processor Assembly (Part No. 1208010-78C-C00). Within the FAW Russian Catalytic Reduction Aftertreatment architecture, this unit acts as a high-temperature reactor. It houses a ceramic honeycomb substrate coated with catalytic metals like Vanadium, optimized for Russian diesel fuel. The primary function is to facilitate the reaction between injected urea (AdBlue) and NOx. This requires precise thermal management; if internal temperatures drop due to Arctic winds, the reaction stalls. Urea then crystallizes, creating solid blockages that can destroy the engine’s backpressure balance.

To maintain heat, the FAW Russian Catalytic Reduction Aftertreatment housing uses double-walled stainless steel with an insulating air gap. This design minimizes heat loss to the freezing environment. Additionally, internal baffles are engineered to create turbulent flow. Turbulence ensures the atomized urea is evenly distributed across the catalyst brick. Without this, “ammonia slip” occurs, failing emissions tests. The robust construction ensures it withstands rapid thermal cycling from -40°C starts to 500°C regeneration temperatures without cracking.

Maintenance access is provided via the Cover Plate – Exhaust Tail Pipe (Part No. 1203018-73W) and the Access Cover (Part No. 1203019-77C). These plates allow technicians to inspect the catalyst for soot or crystal buildup without removing the entire FAW Russian Catalytic Reduction Aftertreatment unit. The sealing of these covers is critical, utilizing high-temperature gaskets to withstand pulsating exhaust pressure. Any leak here compromises sensor readings, leading to ECU fault codes and potential engine derating.

Mounting Logic: Managing Thermal Growth

Mounting the massive FAW Russian Catalytic Reduction Aftertreatment processor requires sophisticated engineering. The system uses a “floating” suspension anchored by the Bracket Assembly – After-Processor (Part No. 1203050-70V). These brackets are structural giants, formed from high-strength low-alloy (HSLA) steel designed to remain ductile at low temperatures. In the FAW Russian Catalytic Reduction Aftertreatment design, they provide a rigid foundation that resists the twisting forces of the truck chassis on uneven mining roads.

However, rigidity alone leads to failure. The stainless steel body expands significantly as it heats up. Direct bolting would cause stress fractures. FAW utilizes the Strap Assembly – After-Processor (Part No. 1203090-73W) to solve this. Two heavy-duty straps wrap around the unit, clamping it securely while allowing for radial expansion. These straps in the FAW Russian Catalytic Reduction Aftertreatment system are lined with friction material to isolate vibration and prevent metal-on-metal abrasion on the canister wall.

This strap-based mounting is a defining feature of the FAW Russian Catalytic Reduction Aftertreatment architecture. It effectively decouples the thermal dynamics of the exhaust system from the mechanical dynamics of the chassis. This ensures that even when the truck twists through a frozen ditch, the sensitive ceramic substrates are cushioned from shock. This prevents internal cracking that would render the expensive component useless.

Fastening Dynamics: High-Torque Security

The system’s integrity is maintained by carefully selected fasteners. Primary loads are handled by the Hexagon Flange Bolt Coarse Shank (Part No. Q1841460). The “Coarse Shank” designation is vital, offering superior resistance to stripping in heavy-duty applications. In the FAW Russian Catalytic Reduction Aftertreatment assembly, the flange head distributes the immense clamping load over a large area, preventing the bolt from digging into the bracket and creating stress risers.

Securing these bolts are the Hexagon Flange Locking Nut (Part No. CQ32614). Standard nuts fail here due to high-frequency exhaust vibration. These locking nuts feature a distorted thread form that mechanically bites into the mating surface, resisting loosening. This eliminates the need for split lock washers in high-stress locations, improving the reliability of the FAW Russian Catalytic Reduction Aftertreatment mount under severe conditions.

For auxiliary connections, the system employs Hexagon Nut (Part No. CQ34012) and Spring Washer (Part No. Q40310). Additionally, maintenance-friendly Combination Bolt (Part No. CQ1460825) with captive washers are used for covers. In a snowy environment, dropping a loose washer means losing it. By using combination bolts, FAW ensures technicians can service the FAW Russian Catalytic Reduction Aftertreatment system efficiently without fumbling with small parts in the cold.

Connectivity Logic: V-Band Clamping

Connecting the FAW Russian Catalytic Reduction Aftertreatment unit to the exhaust stream is the Snap Ring Assembly (Part No. 1203075-50A). This heavy-duty V-band clamp is designed for high-pressure sealing. Unlike flange gaskets requiring multiple bolts, the V-band uses a single tension point for uniform radial pressure. This allows rapid removal for service. The clamp creates a wedging action that pulls flanges together, creating a seal capable of withstanding pressures exceeding 5 bar.

Tensioning is handled by a Hexagon Head Bolt (Part No. CQ1501035). This bolt must withstand high tensile loads at elevated temperatures without stretching. In the FAW Russian Catalytic Reduction Aftertreatment system, a stretched bolt leads to leaks and failed emissions tests. The precision clamp profile ensures perfect pipe alignment, reducing turbulence that could disrupt flow dynamics entering the catalyst.

Ultimately, reliability hinges on these 15 components interacting perfectly. From the chemical coating to the zinc-flake bolts, every detail is optimized for Russia. Ignoring specifications—using a standard bolt or generic strap—compromises the FAW Russian Catalytic Reduction Aftertreatment logic, leading to expensive repairs.

Component Breakdown: 86. Selective Catalytic Reduction After-Processor Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | CQ34012 | Hexagon Nut | 8 |

| 2 | 1203050-70V | Bracket Assembly – After-Processor | 1 |

| 3 | CQ32614 | Hexagon Flange Locking Nut | 4 |

| 4 | Q1841460 | Hexagon Flange Bolt Coarse Shank (Standard) | 4 |

| 5 | 1203090-73W | Strap Assembly – After-Processor | 2 |

| 6 | CQ1501035 | Hexagon Head Bolt | 4 |

| 7 | Q40310 | Spring Washer | 4 |

| 8 | Q40210 | Large Washer | 4 |

| 9 | 1203059-70V | Bracket – After-Processor | 1 |

| 10 | 1208010-78C-C00 | Selective Catalytic Reduction After-Processor Assembly | 1 |

| 11 | 1203018-73W | Cover Plate – Exhaust Tail Pipe | 1 |

| 12 | CQ1460825 | Combination Bolt | 2 |

| 13 | CQ1461030 | Combination Bolt | 2 |

| 14 | 1203019-77C | Access Cover | 1 |

| 15 | 1203075-50A | Snap Ring Assembly | 1 |

Conclusion: Arctic Reliability

The FAW Russian Catalytic Reduction Aftertreatment assembly is a sophisticated engineering solution for polar transport. By combining advanced chemical processing with heavy-duty structural engineering, FAW ensures the CA3250P66K24L1TE5Z leaves a minimal environmental footprint while delivering maximum power. The system’s ability to withstand thermal shock and vibration ensures fleet owners can operate with confidence.

For the maintenance technician, understanding this assembly is key. Replacing a flange bolt with a standard one or overtightening a strap compromises the FAW Russian Catalytic Reduction Aftertreatment system. By adhering to the genuine parts list and respecting the design intent, operators ensure their trucks remain profitable assets in the harsh Russian environment.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.