FAW Russian Intake Ducting: Mastering 12 Critical Components for Flawless Cold-Start Airflow

The FAW Russian Intake Ducting system serves as the respiratory lifeline for the heavy-duty CA3250P66K24L1TE5Z dump truck engine. Designed to conquer the brutal realities of the Siberian tundra, this logic assembly goes beyond simple piping; it is a sophisticated network of thermal-resistant polymers, damping brackets, and high-torque sealing mechanisms. This guide dissects the 12 essential components of the FAW Russian Intake Ducting, analyzing how they ensure clean airflow in conditions below -40°C.

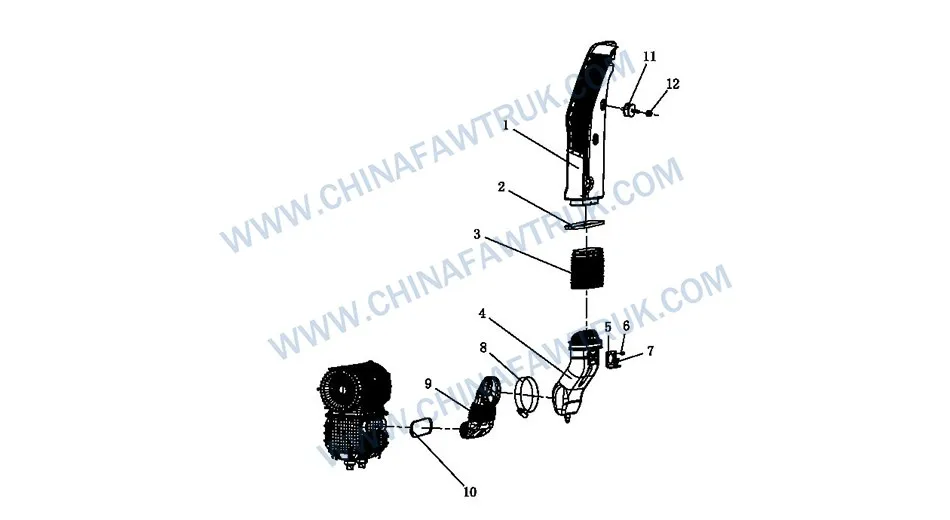

FAW Russian Intake Ducting

Flow Dynamics: The Intake Duct Assembly

The primary conduit for air entering the system is the Intake Duct Assembly (Pattern) (Part No. 1109230-61B-C00). This is not a standard plastic tube; in the context of the FAW Russian Intake Ducting system, it is an engineered component manufactured from high-grade reinforced polymers. The design must reconcile two opposing forces: the high suction vacuum created by the turbocharger and the external impact forces from ice and debris. The internal surface finish is polished to a microscopic level to minimize air resistance, ensuring that the engine breathes freely. This efficiency is a core characteristic of the FAW Russian Intake Ducting architecture, allowing for optimal combustion even when air density fluctuates significantly during winter operation.

Connecting directly to the filtration unit is the Intake Pipe – Air Filter (Pattern) (Part No. 1109291-74U). This pipe features a specific geometric curvature designed to accelerate airflow while reducing turbulence. Turbulence in the intake tract can cause sensor reading errors and reduce combustion efficiency. By utilizing a “Pattern” design, FAW ensures that every replacement part maintains the exact volumetric efficiency of the original FAW Russian Intake Ducting factory unit. The material composition of this pipe includes UV stabilizers and cold-weather plasticizers, preventing the “glass transition” phase where polymers become brittle enough to crack under simple engine vibration.

Bridging the gap between the rigid ducting and the engine intake is the Connecting Hose Assembly – Air Filter (Part No. 1109260-50A). This flexible component is the unsung hero of the FAW Russian Intake Ducting assembly. Made from multi-ply EPDM rubber reinforced with aramid fibers, it absorbs the violent shaking of the diesel engine, isolating the rigid plastic ducts from stress. In Russian winters, lesser rubber hoses freeze into a solid state, transmitting vibration until something snaps. This specific FAW hose remains pliable down to extreme sub-zero temperatures, maintaining the structural integrity of the entire intake line.

Pressure Retention: Worm Drive Clamp Logic

An intake system is only as good as its seals. The FAW Russian Intake Ducting utilizes a redundant clamping strategy to prevent “dusting”—the ingestion of unfiltered air. The primary securing mechanism is the Worm Drive Hose Clamp Assembly (Pattern) (Part No. 1109210-50A). Unlike spring clamps which can lose tension over time, this worm drive design allows for positive, torque-specific tightening. The stainless steel band is perforated to engage the worm gear securely, ensuring that the clamp does not loosen even under the thermal expansion and contraction cycles of a working truck engine, a vital requirement for the FAW Russian Intake Ducting reliability.

For larger diameter connections, the system employs the Worm Drive Hose Clamp Assembly (Pattern) (Part No. 1109210-74U). The size differentiation is critical; using an undersized clamp creates ovalization of the hose, leading to leaks, while an oversized clamp leaves a “tail” that can interfere with other engine components. Complementing these is the specialized Worm Drive Hose Clamp Type B (Part No. CQ676230B). The “Type B” designation refers to a rolled-edge band design. Standard sharp-edged clamps can cut into the soft EPDM rubber of the hoses when overtightened. The Type B clamp prevents this damage, preserving the hermetic seal of the FAW Russian Intake Ducting system.

The strategic placement of these clamps within the FAW Russian Intake Ducting architecture creates a robust barrier against contaminants. This is vital in the dusty environments of mining operations. If a clamp fails, abrasive silica dust enters the cylinders, acting like sandpaper on the piston rings. Therefore, the specification of high-grade, corrosion-resistant steel for these clamps (CQ series) is a direct response to the salted roads of Russia, ensuring the worm gear mechanism remains operable for maintenance even after years of exposure to corrosive slush.

Vibration Management: Brackets and Bases

The intake system spans a significant length across the chassis, making it susceptible to harmonic resonance. To combat this, the FAW Russian Intake Ducting assembly relies on a robust support network. The Connection Base Assembly (Pattern) (Part No. 1109250-58H) acts as the foundational anchor. This component provides a flat, stable platform for the ducting to route through the engine bay. Its design allows for slight lateral movement to accommodate chassis flex, which is common in dump trucks traversing uneven terrain, without transferring that stress to the plastic pipes of the FAW Russian Intake Ducting.

Supporting the vertical load is the heavy-duty Bracket (Part No. 1109311-43B). This metal bracket is more than a simple stay; it is geometrically shaped to resist fatigue cracking. In the Russian cold, metal fatigue accelerates. FAW engineers have optimized the thickness and bend radii of this bracket to ensure it outlasts the vehicle. It positions the ducting away from high-heat sources like the exhaust manifold, preventing the plastic from heat cycling and warping, thus maintaining the precise alignment required by the FAW Russian Intake Ducting.

Perhaps the most critical structural component is the Damping Bracket Assembly – Intake Duct (Part No. 1109220-50A). Note the quantity: there are 5 of these units used in the assembly. These are not rigid mounts; they contain rubber isolators that decouple the ducting from the chassis vibration frequency. By using five distinct damping points, the FAW Russian Intake Ducting system effectively “floats” above the engine. This prevents the high-frequency diesel hum from vibrating the plastic ducts into dust, a common failure mode in inferior intake designs where rigid mounting leads to immediate fracturing.

Fastening Integrity: Bolts and Locking Nuts

The integration of the intake system requires fasteners that stay tight. The FAW Russian Intake Ducting utilizes Combination Bolt (Part No. CQ1461020) and Combination Bolt (Part No. CQ1461025). These “Combination” bolts feature integrated washers that are captive to the bolt head. This design speeds up assembly on the production line but, more importantly, ensures that a washer is never forgotten during field repairs. The washer spreads the clamping load, preventing the bolt head from crushing the plastic mounting tabs of the FAW Russian Intake Ducting components.

Securing the assembly against the relentless vibration of a 30-ton truck is the Hexagon Flange Locking Nut (Part No. CQ32606). There are 5 of these nuts employed, corresponding to the critical mounting points. The “Locking” feature typically involves a nylon insert or a distorted thread design that creates friction, preventing the nut from backing off. In the context of the FAW Russian Intake Ducting, flange nuts are preferred because the wide flange acts as a built-in washer, providing a large surface area for grip. This is essential when bolting metal brackets to the frame.

The selection of these specific fasteners highlights the attention to detail in the CA3250P66K24L1TE5Z. Standard bolts would loosen within the first 1000 kilometers of washboard roads. By standardizing on high-grade CQ series hardware, FAW ensures that the structural integrity of the FAW Russian Intake Ducting system is maintained. Any compromise in hardware quality disrupts the logic of the entire assembly, potentially leading to loose piping and catastrophic engine damage downstream.

Component Breakdown: 82. FAW Russian Intake Ducting Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1109230-61B-C00 |

Intake Duct Assembly (Pattern) |

1 |

| 2 |

1109210-50A |

Worm Drive Hose Clamp Assembly (Pattern) |

1 |

| 3 |

1109260-50A |

Connecting Hose Assembly – Air Filter |

1 |

| 4 |

1109250-58H |

Connection Base Assembly (Pattern) |

1 |

| 5 |

1109311-43B |

Bracket |

1 |

| 6 |

CQ1461020 |

Combination Bolt |

4 |

| 7 |

CQ1461025 |

Combination Bolt |

2 |

| 8 |

CQ676230B |

Worm Drive Hose Clamp Type B |

1 |

| 9 |

1109291-74U |

Intake Pipe – Air Filter (Pattern) |

1 |

| 10 |

1109210-74U |

Worm Drive Hose Clamp Assembly (Pattern) |

1 |

| 11 |

1109220-50A |

Damping Bracket Assembly – Intake Duct |

5 |

| 12 |

CQ32606 |

Hexagon Flange Locking Nut |

5 |

Conclusion: The Logic of Arctic Reliability

The FAW Russian Intake Ducting system exemplifies the engineering philosophy behind the FAW J6P series: logic over simplicity. In the harsh conditions of Russia, a simple pipe is a liability. By integrating flexible damping brackets, roll-edged clamps, and chemically resistant polymers, FAW creates an intake system that is both rigid enough to handle turbo boost and flexible enough to survive chassis torsion. Every component, from the largest duct to the smallest locking nut, plays a vital role in maintaining the clean air supply that the engine depends on, highlighting the necessity of the complete FAW Russian Intake Ducting package.

For fleet owners, the message is clear: when maintaining the intake system, shortcuts are not an option. Using generic clamps or non-reinforced hoses disrupts the carefully balanced logic of the assembly. Only by utilizing the specified genuine parts can one ensure that the CA3250P66K24L1TE5Z continues to operate at peak efficiency, regardless of how far the thermometer drops. Investing in the correct FAW Russian Intake Ducting components is an investment in the longevity and profitability of the entire vehicle.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.